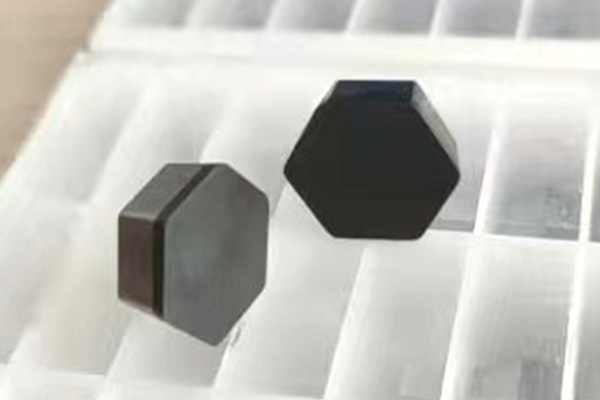

Description: Full Face CBN Inserts

Processing Material: Cast Iron, High Speed Steel, Hardened Steel

Machined Parts: Rolls, Wind Power Bearings, Cast Iron Engine

Machining Type: Semi-Finishing, Finishing

Whatsapp: +8613271562251

Email: halnn@halnn-group.com

| Full face CBN blade style | |||

|

|

|

|

|

|

|  |

1.2750 Inner ring processing case

Difficulties: the wear resistance of the blade is poor, the size of the pressure angle machined to the lower channel is out of tolerance, the roughness is out of tolerance, and the workpiece surface has scratches.

The BN-H200 material has excellent wear resistance and can easily solve customers' problems

Parts:Rough finishing of inner ring ribs

Diameter:2750mm

Material:42CrMo4

Hardness:HRC58-63

Type:BN-H200 RNMN090300

Machining parameter:Vc=190m/min, Fr=0.32mm/r, ap=0.6-0.7mm

2. 2750 outer ring processing case

Difficulties: 1-1.5mm Cutting depth;

Heavy interrupted cutting;

Insufficient wear resistance.

BN-H200 High wear resistance and strong impact resistance

| Insert Materials | Cutting Speed | Tool Life | Efficiency |

| Halnn BN-H200 | 197m/min | 1 PC Obligatory replacement | 60% cost reduction |

| Foreign CBN | 197m/min | 1 PC Obligatory replacement |

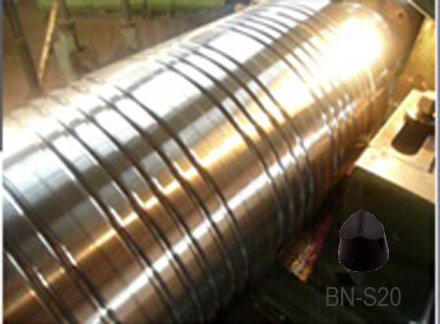

3.BN-S20 Full face CBN Insert Machining HSS Rolls

Materials: HSS Rolls,

Hardness:HSD90,

Insert Model:BN-S20 RCMX120700,

Cutting Parameters:Vc=50m/min, Fr=0.2mm/r

| Insert Materials | Machining Beats | Tool Life/blade | Efficiency |

| Halnn BN-S20 | 2h | 25 grooves/blade | Improve 6 times |

| Carbide Insert | 12h | 3 grooves/blade | / |

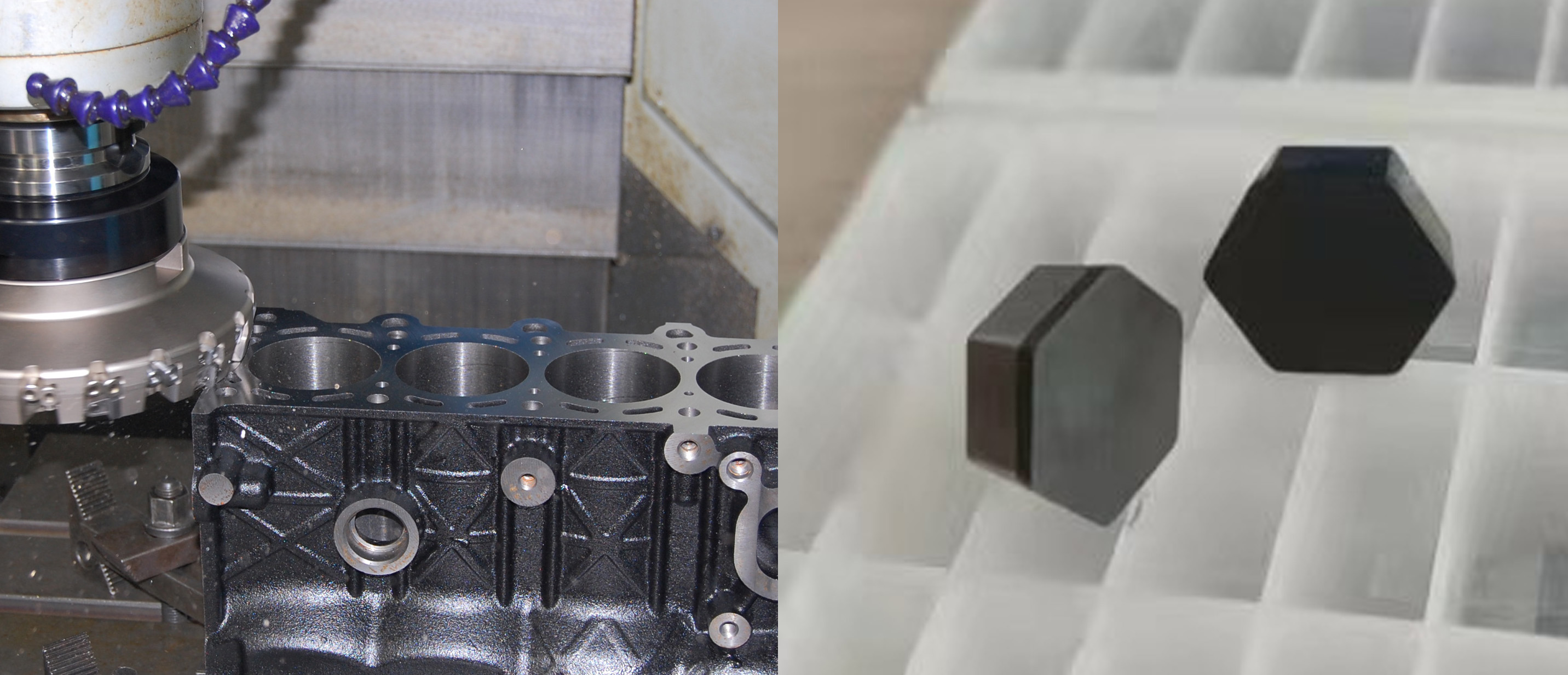

4.Full face CBN insert BN-S300 milling engine cylinder block

Mode: Type: Application:

Mode:CBN tools Type:Solid CBN Insert,PCBN Insert Application:hardened steel

Mode:CBN tools, PCD tools Type:PCBN insert, pcd tools Application:auto parts

Mode:RNMN RCMX-V RCMX-Y PCD Type:BN-K1,BN-S20,CDW010 Application:Rollers

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.