With the diversification of processed materials and the increasing requirements for workpiece processing efficiency and accuracy, the application range of precise and efficient CBN inserts is further expanded. CBN inserts are even used for workpieces that are only Semi quench (both hard and soft materials) and require one-off machining. However, these relatively soft (Semi quench) materials often face tangling problems during machining, which can lead to scratches on the workpiece or even cause it to be scrapped.

Behind this issue are aspects such as material diversity, machining efficiency and precision, winding problems and workpiece protection.

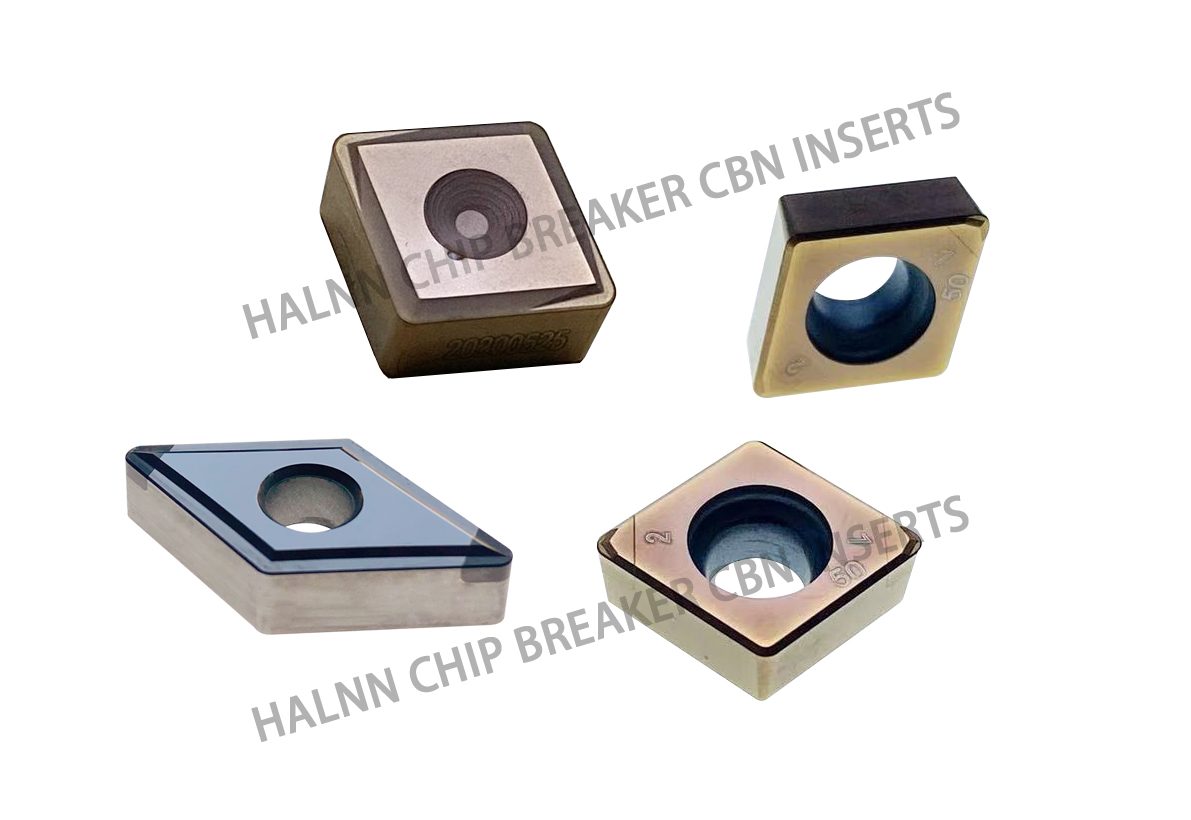

In order to cope with these challenges, Halnn, as a pioneer in the localization of superhard cutting tools, has produced a series of chip breaker CBN inserts with smooth chip removal and uniform chip size, which not only prevents the chips from wrapping around the workpiece or the insert, but also extend the service life of the insert while ensuring good surface quality of the workpiece.

CBN insert with chipbreaker can not only control the chips generated during the cutting process, but also achieve the control of chip curl and breakage.CBN insert with chipbreaker can help slow down the wear of the inserts, reduce the cutting resistance during the processing, there by improving the processing efficiency and improving the surface quality of the processed workpiece.

The chipbreaker of Halnn CBN insert is ground by ultra-precision grinding machine and is the customized products, which is more stable in performance and smoother in appearance compared with the laser-engraved method. The chip breaker CBN insert needs to design the chip breaker geometry according to the conditions of the workpiece being processed, and then the three-dimensional shape is machined on the front face of the cutting tool for testing. At the same time, the design of chipbreaker can also be combined with coating technology to achieve better cutting effect.

Halnn chip breaking CBN inserts have different shapes such as SV, VB, LV, etc.

Halnn chip breaking CBN insert structure includes PCBN inserts, brazed CBN inserts, and overall perforated CBN inserts.

Application range of Halnn CBN inserts chipbreaker:

(1)Post-processing of spray welding of nickel-based alloys on mechanical engineering assembly surfaces such as ball valves: CBN insert with chipbreaker show special effects in this case, which can effectively deal with the astringency of the machined surface and improve the machining quality.

(2)Workpieces with hard and soft surfaces that need to be machined at the same time: For workpieces with uneven material hardness, especially those that need to be machined at the same time with hard and soft machined parts,CBN insert with chipbreaker can effectively break the chips and provide a practical solution for machining.

(3)Hard turning of thin-walled parts: In addition to the chipbreaking function, CBN insert with chipbreaker are able to effectively suppress vibration and vibration patterns, thus improving machining stability and accuracy.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.