Ceramic tools and CBN tools are widely used in manufacturing industry globally. CBN and ceramics are two kinds of cutting tools materials, but in terms of inorganic non-metallic materials, CBN (full name: Cubic Boron Nitride) and alumina, silicon oxide and other traditional ceramic tool materials collectively referred to as ceramic materials. So, in some applications, both ceramic tools and CBN tools are suitable. As a pioneer brand of applying CBN and ceramic tools in heavy-duty machining and hard turning, Halnn Superhard has always believed that ceramic tools and CBN tools belong to a symbiotic relationship, not an antagonistic relationship. Both of them, respectively, play their respective advantages to assist the rapid development of the manufacturing industry.

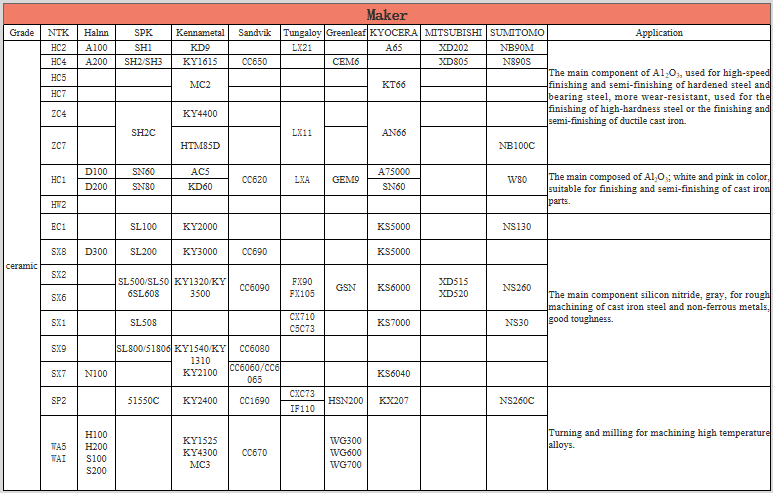

In terms of ceramic inserts, the common brands on the market are Sweden's Sandvik, Germany's SPK, Japan's NTK, the U.S. Green Leaf, Japan's Kyocera, China's Halnn, among which whisker toughened ceramic tools are mainly used in the field of high-temperature alloys, silicon nitride ceramics are used in the machining of hard materials and cast iron, alumina ceramics are used for hard turning. All above applications are overlapped with CBN.

Ceramic tools and CBN tools her ferrous materials cutting. Generally speaking, for hardened steel precision hard cutting, PCBN is most applied; For non-precision hard cutting, ceramic and CBN tools have a lot of overlaps in application, especially in roughing-finishing applications. The segment market of solid CBN inserts is dominated by Chinese manufacturers, among which Halnn is the most famous one. For example:

In cast iron field such as brake discs, brake drums, engine blocks and other gray cast iron automotive parts, ceramic tools from SPK and Sandvik are popular. While, for high-efficiency production lines, customers are preferring solid CBN inserts from SECO or Halnn. In order to cope with the growing demands on specialization, scale and productivity, more and more far-sighted manufacturers noticed the advantages of CBN which are higher cutting speed and longer lifetime. Among these CBN tools, BN-S300 series from Halnn is getting more and more acceptance because of its better performance and comprehensive use of cost.

Followings are posters of Halnn from EMO exhibition from which we could see Halnn is providing solutions including machining methods for brake discs/drums sectors. Reducing the cycle time and increasing productivity by upgrading the inserts that is exactly what the end users need.

Rolling mill field:

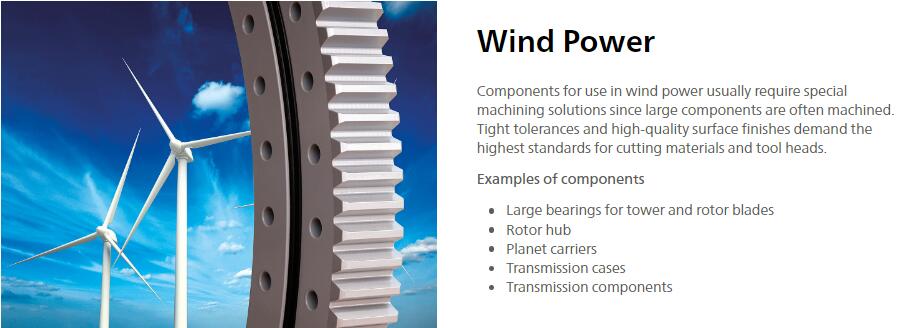

Heavy duty hard cutting field such as wind turbine energy: Coexistence of ceramic and CBN tools, the following content is extracted from SPK and halnn's introduction to this heavy duty hard cutting field, and some pictures are from the EMO exhibition, which are shared with you.

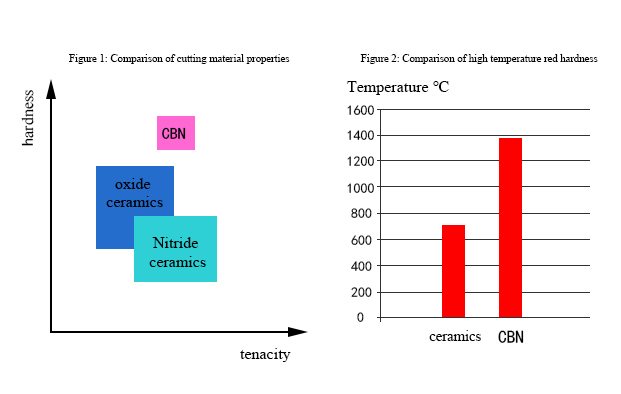

Finally, I would like to popularize the difference in physical properties between PCBN and ceramic inserts:

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.