Full name: Parallel Grinding Wheel, cylindrical diamond wheel, diamond wheel for pdc, Large Diameter Parallel Grinding Wheel, Diamond Bruting Wheel

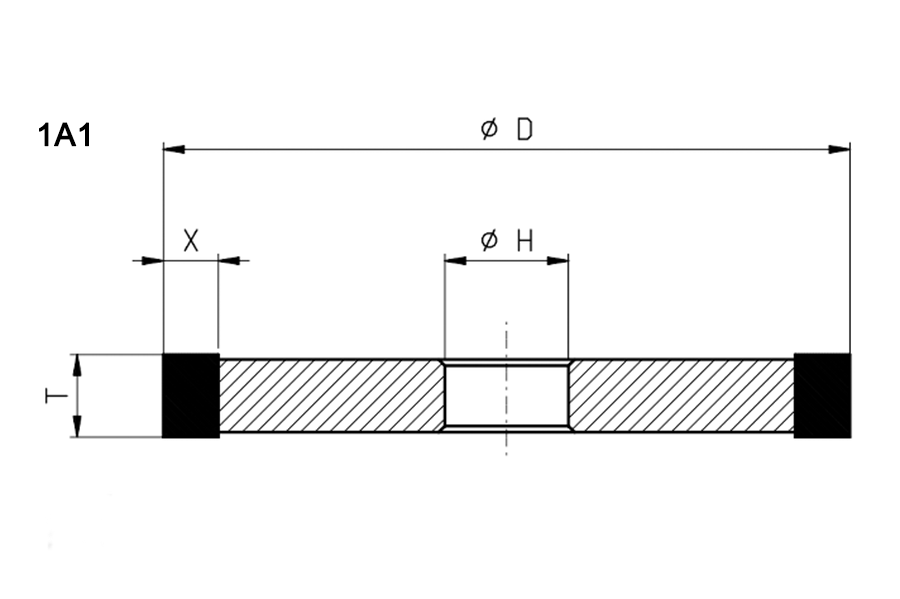

Model: 1A1, 3A1, 14A1etc.

Adhesive: Vitrified, resin

Application: Cylindrical grinding for PCD tools& PDC cutter

Whatsapp: +8613271562251

Email: halnn@halnn-group.com

Parallel Grinding Wheel is widely used for cylindrical grinding for PCD tools, PDC cutter

Specifications:

| D | T | H | X |

25~750 | 3~60 | 6~305 | 2~15 | |

Granularity: 325/400, W40 (500#), W28 (600#), W20 (800#), W10 (1500#), W5 (3000#), W3 (5000#) | ||||

Common specifications:

200×32×10×10 | 200×32×20×10 | 250×75×10×10 | 350×127×10×10 | 400×127×10×10 |

Please note: Other specifications can be customized according to customer drawings or needs.

Granularity(Grain size):

Machining Type | Grain Size | Characteristics |

Precision Finishing | W5(3000#, D7) | Getting a brilliant quality of machined surfaces |

W3.5 (4000#,D3) | ||

Finishing | W10(1500#, D15A) | Getting a very good quality of machined surfaces |

W7(2000#, D15B) | ||

Roughing | W40(400-500#, D35) | Regrinding a blade edge profile and sharpening of much worn inserts |

W28(600-700#,D20) | ||

Universal | W20(800-1000#,D20) | Standard grain size also can get a high sharpening efficiency, good quality surfaces |

Advantage of Halnn Parallel Grinding Wheel

1. High efficiency

2. Good self-sharpening

3. Excellent surface finish

4. Long service life

5. Fast delivery

Mode:RNMN RCMX-V RCMX-Y PCD Type:BN-K1,BN-S20,CDW010 Application:Rollers

Mode:CBN tools Type:Solid CBN Insert,PCBN Insert Application:hardened steel

Mode: Type: Application:

Mode:Milling,Drilling,Reaming Type:PCD tools,Carbide coated tools Application:Aerospace field

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.