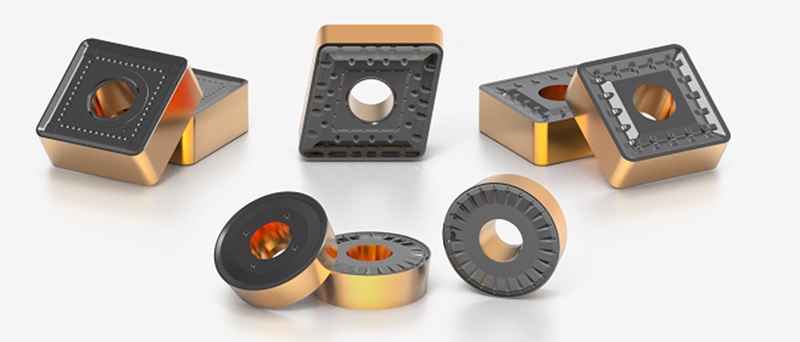

Experience unmatched performance and durability with Halnn’s Heavy Turning Inserts, designed to handle the most demanding machining tasks. Whether you're working with tough alloys, hardened materials, or facing interrupted cuts, our heavy-duty turning inserts deliver superior cutting performance and reliability for high-efficiency machining.

Built with superior toughness to withstand extreme cutting forces in high-feed and high-depth operations.

Optimized cutting geometries ensure smooth chip flow and excellent surface finishes even under heavy loads.

Manufactured with premium CBN, ceramic, or carbide materials, these inserts deliver extended tool life in challenging conditions.

Capable of maintaining cutting performance in high-temperature environments, reducing the need for frequent tool changes.

Designed to fit a wide range of tool holders and machines, making them versatile for various machining setups.

1. Increased Productivity: High material removal rates and consistent performance reduce cycle times.

2. Long Tool Life: Superior material quality and design minimize wear, lowering overall tooling costs.

3. Improved Surface Quality: Achieve precision finishes even on tough materials.

4. Reduced Downtime: Reliable inserts mean fewer tool changes and smoother operations.

5. Versatile Solutions: Designed to meet the unique demands of diverse heavy-duty turning applications.

Mode:RNMN RCMX-V RCMX-Y PCD Type:BN-K1,BN-S20,CDW010 Application:Rollers

Mode:CBN tools Type:cylinder liner Application:auto parts

Mode:CBN tools Type:Solid CBN Insert,PCBN Insert Application:hardened steel

Mode:Milling,Drilling,Reaming Type:PCD tools,Carbide coated tools Application:Aerospace field

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.