1. Continuous Cutting:The inner bore and gear shaft are machined by turning instead of grinding.

Cutting State:Continuous Cutting,Dry Cutting.

The processing case is shown in the figure below.

| Machining Part | Gear Wheel |  | |

| Machining Materials | Hardened Steel | ||

| Workpiece Hardness | HRC58-63 | ||

| Machining Type | Continuous Turning | ||

| Insert Model | BN-H10 CNGA120408S01020 | ||

| Cutting Parameters | Vc=180m/min,Fr=0.1mm/r,ap=0.2mm | ||

| Machining Effect | |||

| Insert Materials | Cutting Speed | Tool Life/Edge | Efficiency |

| Halnn BN-H10 | 180m/min | 800 pcs | 6 s / pcs |

| Ceramic Insert | 130m/min | 150 pcs | 8.5 s / psc |

CBN insert brand BN-H10 is recommended for continuous cutting:

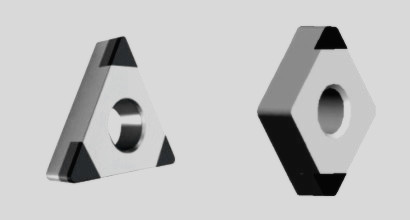

The wear resistance and collapse resistance of BN-H10 are balanced.Roughness within Ra0.4 can be obtained by machining with it.BN-H10 is a edge-welded CBN insert. The cutter drawing is as follows:

CBN insert BN-H11 can also be used for continuous cutting:

Specialty:More CBN cutting edge makes the processing cost lower.The tool structure of CBN inserts BN-H11 is shown in the figure below.

Cutting parameters that are frequently used for continuous cutting

Linear velocity:Vc=120-230m/min;fn=0.06-0.25mm/r

Back cutting depth:ap=0.15mm;Dry Cutting.

Discontinuous gear cutting cases and the brand description of the CBN inserts for Finishing:Gear needs to be machined after quenching its end face.However, when there are bolt holes on the end face of the gear or oil holes in the inner hole of the gear, there will be a process of "intermittent processing" in hot finishing.This process requires excellent fracture toughness and collapse resistance of the tool. In this case, brands CBN inserts BN-H20 and BN-H21 are generally selected.

| Machining Part | Gear Wheel |  | |

| Machining Materials | Gear Steel | ||

| manufacturing procedure | HRC58-63 | ||

| Machining Type | Medium Intermittent Cutting | ||

| Insert Model | BN-H20 WNGA080408S01020 | ||

| Cutting Parameters | Vc=120m/min,Fr=0.1mm/r,ap=0.25mm | ||

| Machining Effect | |||

| Insert Materials | Cutting Speed | Tool Life/Edge | Single Tool Fee |

| Halnn BN-H20 | 120m/min | 700 pcs | 0.1$ |

| Other PCBN Insert | 120m/min | 650 pcs | 0.1$ |

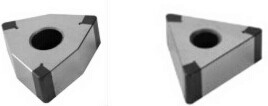

BN-H20 brand CBN inserts for intermittent cutting:

Medium intermittent cutting with CBN inserts are more economical.

Cutting line speed:Vc=100-180m/min,fn=0.07-0.15mm/r

Intermittent Cutting with New product BN-H21 tools.BN-H21 is a strong intermittent cutting tool which is welding insert composite structure.

2. High Allowance Cutting or Rough Machining Tool Machining Cases After Heating

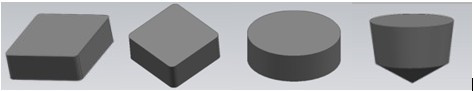

The CBN insert BN-S20 brand integral PCBN insert can be used for rough machining and discontinuous machining of hardened steel with large allowance.Its single side back feed ap up to 7.5mm.CBN insert BN-S20 can be used for machining hardened gear rings, repairing molds, and rough turning other hardened steel (hardness HRC45-HRC68) parts instead of grinding.

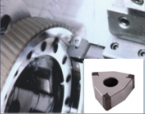

The case is shown in the diagram below

BN-S20 CBN inserts can be used for carburized steel in strong intermittent cutting.The deformation of large gear (gear ring) after carburizing and quenching is serious.The outer ring deformation of gear ring is up to 2mm.The hardness of gear after quenching is HRC60-HRC65.

Cutting Line Speed:50--70m/min

The Depth of The Turning:1.5--2mm

Feed Per Revolution:0.12-0.2mm

| Machining Part | Gear Wheel |  | |

| Machining Materials | Hardened Steel | ||

| manufacturing procedure | HRC60 | ||

| Machining Type | Finish Turning | ||

| Insert Model | BN-S20 | ||

| Cutting Parameters | Vc=90m/min,Fr=0.12mm/r,ap=2.5mm | ||

| Machining Effect | |||

| Insert Materials | Cutting Speed | Tool Life/Edge | Final Failure Mode |

| Halnn BN-S20 | 90m/min | 5 pcs | Normal Wear and Tear |

| Other PCBN Insert | 45m/min | 0.3 pcs | Destroied |

BN-S20 CBN inserts have better impact resistance than the original imported cutting tools.Its life is 6 times that of the original cutting tool when the cutting depth is increased by 3 times and cutting efficiency increased by 6 times.

Or feel free to contact with us sales@halnntools.com, Whatsapp:+8613271562251.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.