Graphite is a non-metal material and is widely used in graphite molds, graphite crucibles, graphite battery plates, etc., especially in today's increasingly serious energy and environmental pollution problems. The development of new energy vehicles has been the implementation of national energy conservation and emission reduction, and the development of low-carbon economy. As one of the key parts of the fuel cell which drives the new energy vehicle, the performance of the graphite plate has directly effect the output power and service life of the entire battery stack, so its quality is required to be very high.

Although graphite is a simple cutting material, it is easy to break due to brittleness, edge chipping, and tool wear during processing, which affects the surface performance of the product. It is recommended to use halnn PCD tools for turning, such as CDW010 and CDW025.

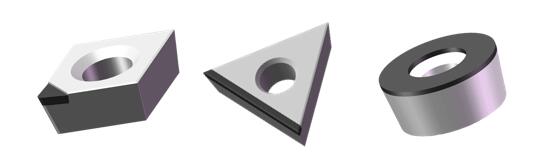

Some enterprises in graphite turning often use carbide tools to process, they are not wear-resistant and have too short life., but this problem does not occur when using PCD tools. PCD tools are synthetic polycrystalline diamond tools with extremely high hardness and can be made of PCD inserts, PCD milling cutters, PCD drills, PCD non-standard insert and other structural forms.

The PCD tools for turning graphite were mainly welding tools in the early days. At present, CNC inserts have been used instead of welding tools to process graphite. The PCD CNC insert of CDW010 and CDW025 materials belong to the national standard model, which is convenient to match with the turning tool holder, and is easy to disassemble and replace. Both CNC lathes and machining centers can be used. Compared with traditional carbide inserts, higher speeds can be used for machining, and the tool life is also greatly improved.

| Material | Recommend PCD insert | Cutting Parameters | ||||

| Vc(m/min) | Fr(mm/r) | Ap(mm) | ||||

| Graphite | CDW302 | CDW025 | CDW010 | 100-600 | 0.1-0.5 | 0.05-2.0 |

In addition to PCD inserts, for graphite parts, Halnn can also provide PCD end mills and milling inserts, PCD drill bits, diamond-coated tools and other products, providing a complete cutting solution for graphite processing.

The tool structure of graphite milling tools includes rod-shaped milling cutters and milling inserts. The types are: PCD end mills, PCD ball end mills, PCD single flute milling insert, pcd two flutes milling insert, pcd groove milling insert, pcd Chamfering insert, diamond pcd face milling cutters, pcd milling inserts and CVD diamond coating milling cutters, etc.

The forms of graphite hole processing tools are: pcd drill bit, pcd inner hole turning tool, pcd boring tool, pcd milling insert, cvd diamond coated drill bit, etc.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.