For processing compressor companies, CBN tools with low production cost and high processing efficiency have become the main choice to be alternatives of carbide tools. However, when processing compressors, due to the wide variety of compressor components, CBN tool manufacturers are uneven. , The selection of CBN tools has become a difficult problem for many companies. Today, the author will combine his own research data and the feedback of processing compressor companies to talk about how to select the most efficient CBN tools when processing various gray cast iron compressors.

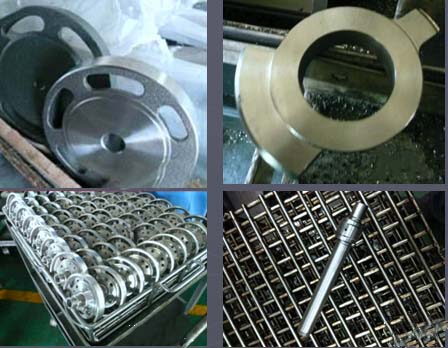

As the most important component of air conditioners, processing compressors has always been the top priority of production enterprises, especially the sealing plates (flanges) that need to be mass-produced, which will produce a lot of heat during high-speed cutting and mass-processing processes. Heat causes abnormal phenomena such as rapid wear of the tool. In addition, gray cast iron often has defects such as hard spots, sand inclusions, and pores, and the working conditions are slightly complicated. Although CBN tools have a series of advantages such as high hardness, high heat resistance, high chemical inertness.Which make up for the shortcomings of carbide tools perfectly .However, due to the differences in the production technology and raw material quality of CBN tool manufacturers, the life of CBN tools is also different.

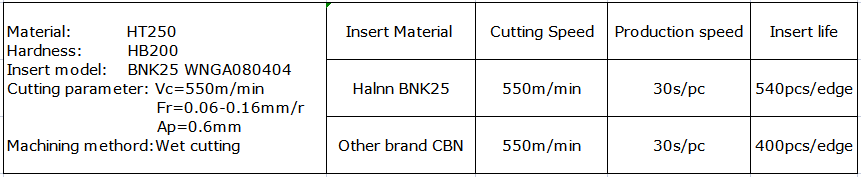

In order to find out the performance of various CBN tools, the author has organized and analyzed the current mainstream CBN tool grades for processing compressors. The specific reference data are as follows:

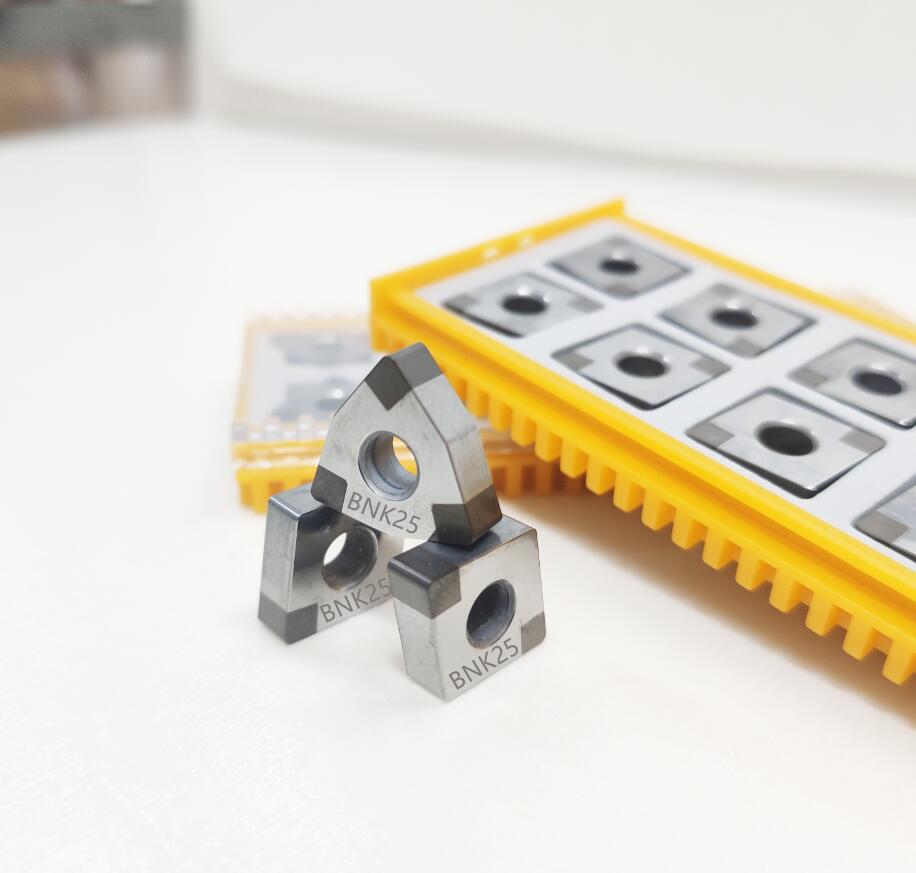

As can be seen from the above image, as a CBN tool, the life of the BNK25 is significantly improved under the same working conditions, which should be the reason why the CBN tool is popular in the processing of compressor gray cast iron.

In addition, the author found that BNK30 has also won the favor of the market with its excellent performance when processing compressor gray cast iron cylinders.

According to public information, BNK30 grade CBN tools can perform high-speed machining for gray cast iron at a cutting speed of 600-2000m/min, and can still work normally at a high temperature of 1000 °C, especially in the field of finishing, BNK30 life and stability are higher or more 50% than homogeneous products.

As the main CBN tool for processing compressor gray cast iron, Halnn BNK series tools stand out from the crowd of CBN tools with their excellent performance, occupying the field of processing compressor cylinders, upper bearings, sealing discs and other gray cast iron. There is a big market, but Halnn is still working hard on full solution of machining the compressor.

Speaking of all, when processing gray cast iron of compressors, how to choose CBN tools is the most efficient. I think everyone has a simple understanding. BNK30 can be used for processing cylinders, and BNK30 can be selected for processing upper bearings and sealing plates (flanges). BNK25 can help you improve processing efficiency and reduce production costs in minutes.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.