In addition to the same high strength and high modulus as resin-based composite materials, metal matrix composites can withstand high temperatures, and are non-combustible, non-moisture-absorbing, good thermal and electrical conductivity, and radiation-resistant. It is an eye-catching high-temperature material for aerospace and can be used as a surface material for aircraft turbine engines and rocket engine hot spots and supersonic aircraft.

Metal matrix composites can be divided into aluminum matrix composites, magnesium matrix composites, titanium matrix composites, nickel matrix composites, copper matrix composites, superalloy matrix composites, intermetallic compound matrix and Refractory metal matrix composites, etc.

The cutting process of metal matrix composite materials includes: turning, milling, reaming, drilling, cutting, etc. In the specific cutting process, which insert is more suitable to choose? Let's see the text

Performance characteristics of metal matrix composites

Aluminum and its alloys are suitable as the matrix of metal matrix composites. The reinforcement of aluminum matrix composites can be continuous fibers, short fibers, or particles from spherical to irregular shapes. At present, aluminum-based composite material reinforced particle materials include SiC, AL2O3, BN, etc., and intermetallic compounds such as Ni-Al, Fe-Al and Ti-Al are also used to strengthen particles.

The performance of aluminum matrix metal composites depends on the characteristics, content, distribution, etc. of the matrix alloy and the reinforcement. Compared with aluminum alloys, aluminum matrix composites have many excellent properties: 1. Low density; 2. Good dimensional stability; 3. Strength, modulus and plasticity; 4. Wear resistance; 5. Fatigue and fracture toughness ; 6. Thermal performance

Applications of metal matrix composites

1. Application in the automotive field

The application research of aluminum matrix composite materials in metal matrix composite materials in the automotive industry started earlier, such as aluminum matrix composite material engine pistons, particle reinforced aluminum matrix composite material automotive brake discs, particle reinforced aluminum matrix composite material automotive gearboxes and other automobiles. The weight of parts is reduced, and the wear resistance is improved, the noise is significantly reduced, and the friction and heat dissipation are fast; the automobile gearbox made of aluminum matrix composite material is better than the aluminum alloy gearbox in terms of strength and wear resistance. Significant improvement. Aluminum alloy composite materials can also be used to manufacture brake system components such as brake rotors, brake pistons, brake pads, and calipers. Aluminum matrix composites can also be used to manufacture automotive drive shafts, rocker arms and other automotive parts.

2. Application in aerospace field

With the development of modern science and technology, higher and higher requirements are put forward for the performance of materials. Especially in the field of aerospace, it is necessary to manufacture light, flexible and high-performance aircraft, satellites, etc., so the application of composite materials accounts for more and more. Such as aluminum-based composite materials, titanium-based composite materials, nickel-based composite materials, high-temperature alloy-based composite materials, etc.

3. Application in electronic and optical instruments

Aluminum-based composite materials, especially reinforced aluminum-based composite materials, are suitable for manufacturing electronic devices such as lining materials and heat sinks due to their small thermal expansion coefficient, low density, and good thermal conductivity. In the application research of precision instruments and optical instruments, aluminum matrix composites are used to manufacture telescope brackets and secondary mirrors. In addition, aluminum matrix composites can also be used to manufacture precision parts of inertial navigation systems, rotating scanning mirrors, infrared observation mirrors, laser mirrors, laser gyroscopes, mirrors, mirror bases and optical instrument brackets and many other precision instruments and optical instruments.

4. Application in sporting goods

Aluminum matrix composites can replace wood and metal materials to make tennis rackets, fishing rods, golf clubs and snowboards. The bicycle sprocket made of particle-reinforced aluminum-based composite material is light in weight, high in rigidity, and not easy to be deformed, and its performance is better than that of aluminum alloy sprocket.

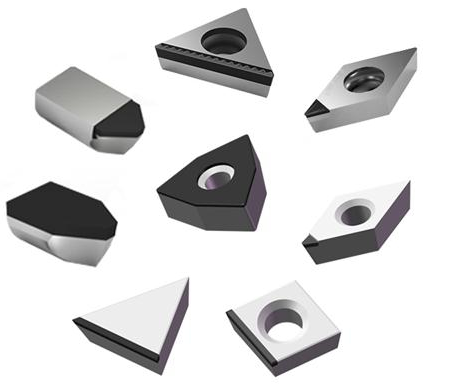

Selection of Insert Material for Machining Metal Matrix Composites

Although metal matrix composites can be made into parts with different precision and different forms through various small or no cutting processes, cutting is still inevitable for workpieces with higher precision requirements. Due to the great abrasiveness of the reinforcing phase in metal matrix composites, traditional tool materials such as high-speed steel and cemented carbide can no longer meet the requirements of cutting metal matrix composites, especially finishing.

In recent years, various industrialized countries in the world and major domestic companies are scrambling to develop new polycrystalline diamond cutting tool materials to solve the cutting processing problems of metal matrix composite materials. Among them, the most representative ones are the CDW010, CDW025 and CDW302 series of polycrystalline diamond (PCD) insert materials developed by Zhengzhou Halnn Superhard Company. In general, the thicker the particles, the better the wear resistance of the tool.

CDW010 material, CDW025 material and CDW302 material belong to synthetic polycrystalline diamond (PCD) inserts. The so-called polycrystalline PCD inserts are made of natural or synthetic diamond powder and binder (including cobalt, nickel and other metals) in a certain proportion. It is sintered at high temperature (1000-2000°C) and high pressure (50-100,000 atmospheres).

Advantages of Halnn superhard diamond (PCD) inserts in cutting metal matrix composites

Correct selection of tool material and cutting amount can ensure the processing quality and high processing efficiency of metal matrix composites. The advantages of Halnn superhard diamond (PCD) inserts in processing metal matrix composites are as follows:

1. Long tool life

Halnn superhard PCD tools process metal matrix composites, and the average tool durability is 50-100 times that of other tool materials. Moreover, when the wear of other tool materials increases sharply, the wear of Halnn superhard PCD tools and diamond-coated tools rate remained stable.

2. Good surface finish

Built-up edge and reinforcing phase are two main factors affecting the surface roughness of metal matrix composites. Built-up edge will promote the formation of scales during the cutting process, which will reduce the quality of surface processing, and Halnn superhard PCD tools Compared with other tools, there is very little built-up edge, and the obtained surface roughness Ra is the smallest, and the finish is also the best

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.