In the realm of precision machining, maintaining stability and accuracy is essential. One of the significant challenges in turning operations is managing vibrations, which can adversely affect the quality of the finished product. Halnn, a leader in machining solutions, offers an advanced solution with its vibration-damped boring bars for turning. These tools are meticulously designed to enhance machining performance, providing numerous benefits across various industries.

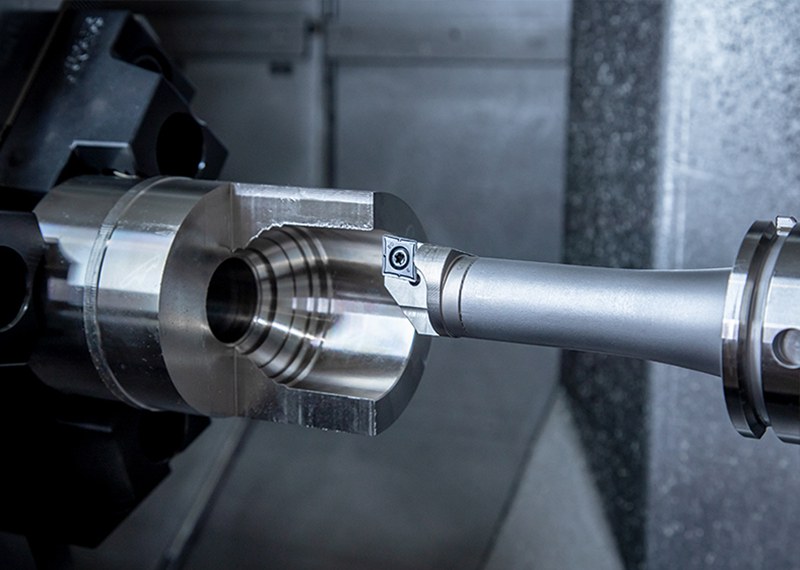

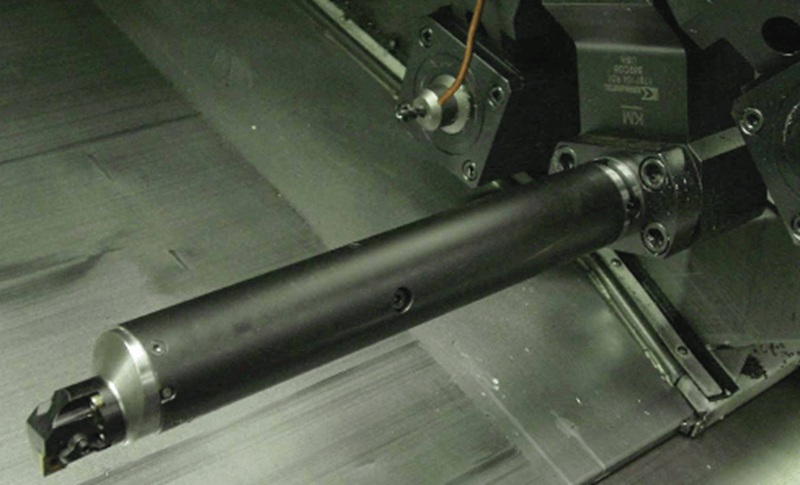

Vibration-damped boring bars are specialized machining tools engineered to minimize vibrations during turning operations. These bars incorporate design features and materials that effectively absorb and dissipate vibrations, ensuring a smoother and more stable cutting process compared to conventional boring bars.

Using vibration-damped boring bars offers several advantages:

Enhanced Precision: Reduced vibrations lead to more accurate cuts and tighter tolerances.

Improved Surface Finish: A smoother cutting process results in superior surface finishes.

Extended Tool Life: Less vibration reduces wear and tear, prolonging the tool’s lifespan.

Increased Productivity: Enhanced stability allows for higher cutting speeds and feeds, improving overall efficiency.

These boring bars utilize various damping techniques, such as internal dampers and specialized materials, to absorb and dissipate vibrations. The design includes elements like tuned mass dampers and viscous dampers, which counteract the oscillations that occur during cutting. This sophisticated damping mechanism ensures that the cutting process remains stable, even under challenging conditions.

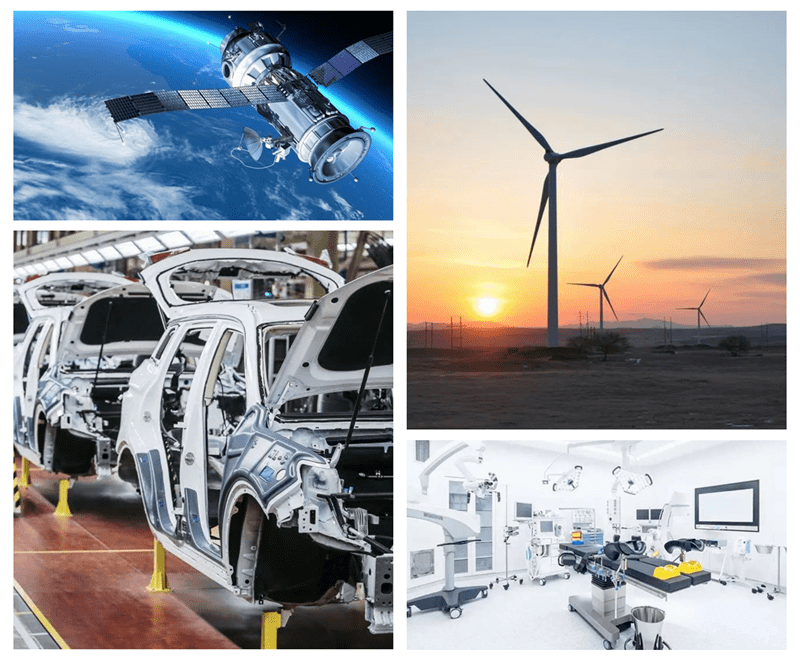

Halnn's vibration-damped boring bars are ideal for several industries, including:

Aerospace: Machining turbine blades and other critical components with high precision.

Automotive: Ensuring accurate machining of engine parts and transmission components.

Medical Devices: Producing intricate and precise components for medical equipment.

General Engineering: Enhancing the quality of various machined parts.

Selecting the appropriate boring bar involves considering factors such as the material being machined, the diameter and length of the bar, and the specific cutting conditions. Ensuring a proper match between the tool and the application is crucial for optimal performance. Halnn offers a range of vibration-damped boring bars to meet diverse machining needs, ensuring that you can find the perfect tool for your specific requirements.

Maintaining these tools involves regular inspection, proper handling, and adherence to recommended cutting parameters. Addressing common issues such as tool wear and ensuring proper lubrication can prolong the tool's life and maintain its performance. Regular maintenance checks and following the manufacturer’s guidelines can significantly enhance the tool’s effectiveness and lifespan.

Halnn stands out in the machining industry due to its commitment to quality and innovation. Our vibration-damped boring bars are designed with cutting-edge technology to deliver unmatched performance. Customers worldwide trust Halnn for reliable and efficient machining solutions. Our dedication to customer satisfaction and continuous improvement ensures that we provide tools that meet the highest standards of quality and performance.

Vibration-damped boring bars are specialized tools designed to minimize vibrations during turning operations. They incorporate damping mechanisms that absorb and dissipate vibrations, resulting in more stable and precise machining.

These boring bars are crucial because they enhance machining precision, improve surface finish, extend tool life, and increase productivity by allowing higher cutting speeds and feeds.

Vibration-damped boring bars utilize internal dampers and specialized materials to absorb and counteract vibrations. These mechanisms ensure a smoother and more stable cutting process, even under challenging conditions.

Industries such as aerospace, automotive, medical devices, and general engineering benefit from using these tools due to their need for high precision and superior surface finishes in machined parts.

Selecting the appropriate boring bar involves considering factors like the material being machined, the diameter and length of the bar, and the specific cutting conditions. It's essential to match the tool to the application for optimal performance.

Regular maintenance includes inspecting the tool for wear, proper handling, adhering to recommended cutting parameters, and ensuring proper lubrication. Following these guidelines can prolong the tool's life and maintain its performance.

Yes, these boring bars are versatile and can be used with a variety of materials, including metals, alloys, and composites. It's important to choose the right bar and settings for the specific material being machined.

By reducing vibrations, these boring bars allow for higher cutting speeds and feeds, which improves overall machining efficiency. This leads to faster production times and increased output.

Halnn’s vibration-damped boring bars are designed with cutting-edge technology to deliver unmatched performance. Our commitment to quality, innovation, and customer satisfaction ensures that our tools meet the highest standards.

Vibration-damped boring bars are essential for achieving precision and stability in turning operations. By minimizing vibrations, these tools enhance accuracy, surface finish, and productivity. Halnn’s expertise in machining solutions ensures that our vibration-damped boring bars meet the highest standards of quality and performance.

For more information about Halnn's vibration-damped boring bars and other machining solutions, visit our website: https://www.halnncbn.com/, contact us via email at halnntools@halnn-group.com, or reach out on WhatsApp at +8615515925975. Discover how Halnn can enhance your machining operations with cutting-edge precision tools.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.