Hi everyone! This is Joanna with Halnn Group. I am glad to be here and give a brief introduction of our production series.

The first one is Heavy duty TM PCBN series. Compared to other CBN materials, heavy-duty cutting series is more suitable for longer processing time, larger cutting depth and interrupt cutting conditions. They are very excellent in processing difficult materials such as high manganese steel and high chromium cast iron. The series could compete with world famous brand in this field.

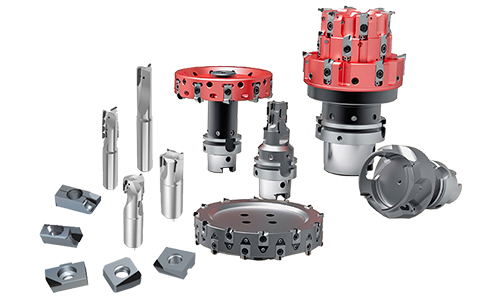

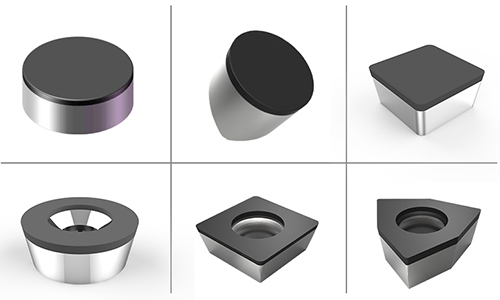

The second one is PCBN/PCD full face series. We got 3 advantages in this series. The productivity could be greatly increased by higher cutting speed and feed rate; The cost could be reduced by increased cutting tips; It is more suitable for precision processing due to its strict control on dimensional accuracy. Therefore, this series would get significant advantage when being applied to industries such as wind power, engineering machinery and processing large parts.

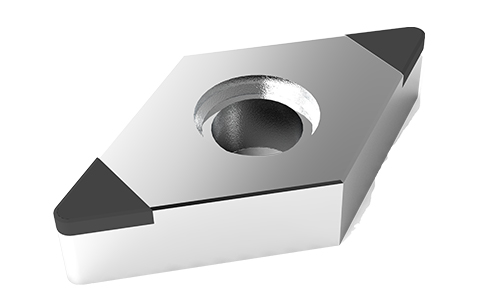

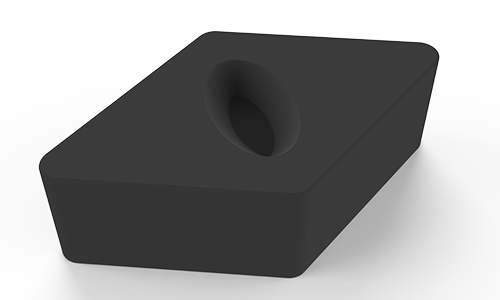

The third is PCBN inserts from Lengthen series. This series of Insets could be applied to finish processing with small cutting depth, as well as heavy-duty processing with big cutting depth. Compared with standard inserts, the inserts has a longer tip and can be customized with different inserts lengths. In the case of large cutting depth, the standard inserts needs to be processed many times; the Lengthen inserts can complete the process in one time, greatly improving the processing efficiency.It can be used for heavy duty and has high processing efficiency. At the same time, the cutting edge has been treated with a special process, which has high edge strength and good stability, and can better control the accuracy requirements of the parts being processed.

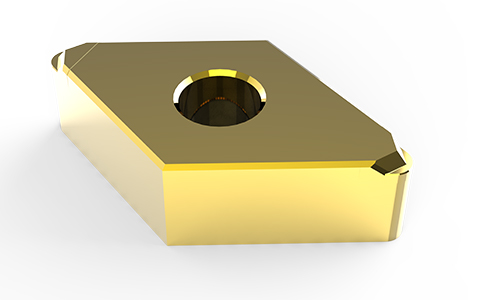

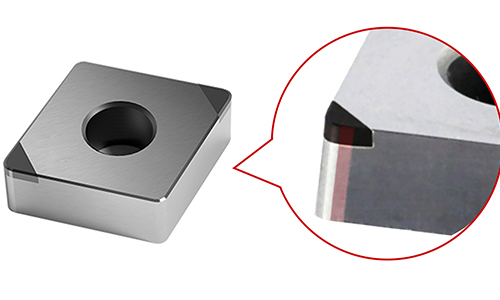

The fourth is the Breaking-G PCBN/PCD Inserts series. They are with chip-breakers which can solve the problems cased by chips, ensuring the parts good surface quality and tool service life. Chip breaker is process by ultra-precision grinding machine. With more stable performance, smooth surface, longer work life could be guaranteed.

The fifth one is Wiper CBN series, Wiper CBN inserts which are suitable for lathes and workpieces with high rigidity. Higher surface quality could be achieved under same feed rate, or higher feed rate under same requirement of Ra.0.1

The sixth one is the Fix-STM CBN positioning pit series. CBN Insert with Positioning Pit are mainly in solid CBN structure. The design of fix-bore is convenient for clamping. It is especially suitable for contour machining and speed cutting.

The seventh one is High Finish PCD polish tool .It is mainly used for mirror-surface processing, and is widely used in plastic abrasive tools and optical molds. The surface finish is within Ra0.1.

The eighth is the repairment service. The substrate production time is long and the cost is high for some non-standard tools. The old inserts could be repair a new tip or regrinding. In this way,we have faster response times and lower costs.