Excellent wear resistance: Halnn PCBN tools are carefully selected from high-quality CBN materials, with good wear resistance, which can effectively avoid the sharp wear of the cutting tool during the processing process, thereby improving the tool's service life.

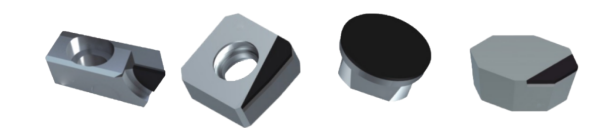

Optimized cutting edge treatment: Halnn has rich experience and practice in cutting edge treatment, which can improve the life of cutting tools and reduce burrs generated during the processing to ensure processing quality.

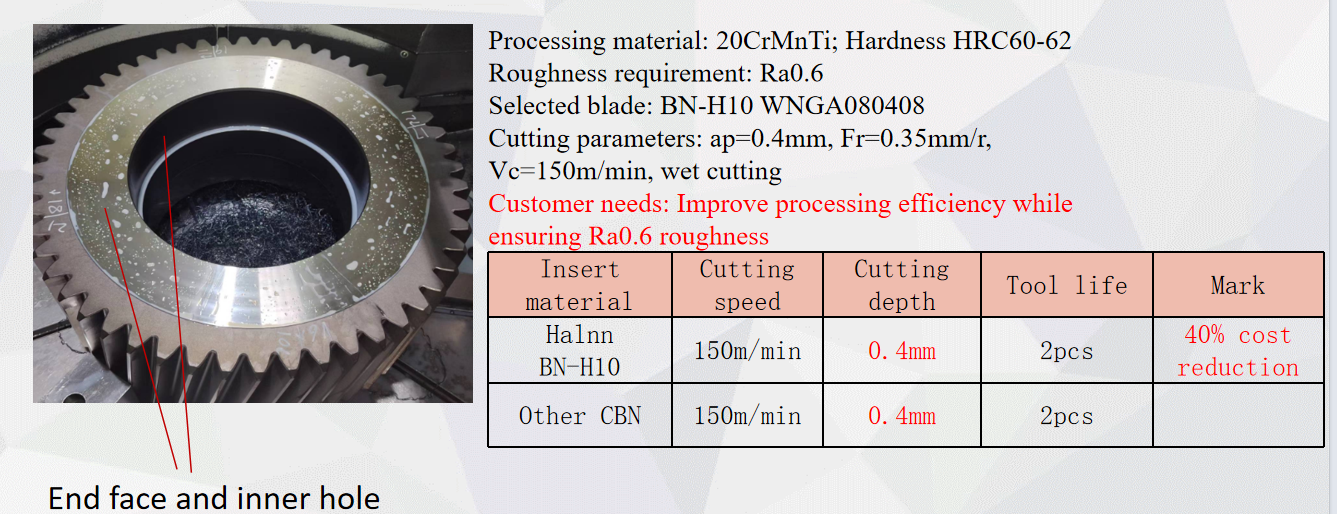

High surface quality: Using Haln PCBN cutting tools can achieve a better surface roughness, reaching within Ra0.6, while maintaining stability in dimensional accuracy.

Customized services: Halnn provides a "tailored" service that offers customized solutions according to specific customer needs, helping customers significantly improve production efficiency.

Innovative Technology: Halnn continuously launches innovative products, such as the Heavy dutyTM series PCBN Toolss, which use ceramic binders instead of traditional metal binders to improve tool performance in heavy-duty and high-temperature cutting conditions.

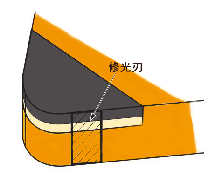

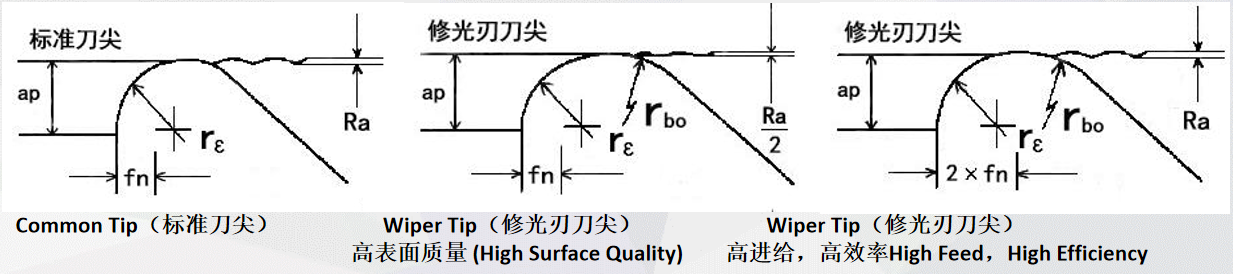

Compared with traditional PCBN inserts, Halnn PCBN wiper inserts can achieve higher surface quality under the same feed rate, or adopt a larger feed rate while ensuring surface quality to reduce the processing time of a single piece and improve processing efficiency.

Export Quality: Some of Halnn's PCBN products are exported to the world and show industry-leading positions in certain segments, demonstrating the international competitiveness of its products.

In summary, Halnn's PCBN cutting tools provide efficient and durable cutting tools for equipment manufacturing industry through continuous technological innovation and service optimization, meeting the needs of different customers, and establishing a good reputation in domestic and foreign markets.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.