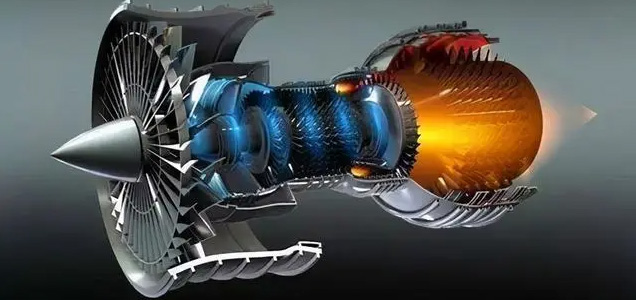

High-temperature alloys refer to a type of metal material based on iron, nickel and cobalt, which can work for a long time at high temperatures above 600°C and under certain stresses, and have excellent comprehensive properties.

According to the matrix elements, they can be mainly divided into iron-based high-temperature alloys, nickel-based high-temperature alloys and cobalt-based high-temperature alloys, and are mainly used to manufacture turbine blades, guide blades and turbine disks for aviation, ships and industrial gas turbines.

As the most difficult material to process among all kinds of difficult-to-cut materials, high-temperature alloys have the following processing difficulties:

(1) High resistance to plastic deformation and severe work hardening, resulting in large cutting forces, which are 2-3 times greater than those of ordinary steel.

(2) Poor thermal conductivity, high temperature during cutting, causing rapid wear of the inserts.

(3) Chips adhere to the cutting edge surface of the inserts, which is very easy to produce built-up edge, affecting the surface quality of the workpiece being processed.

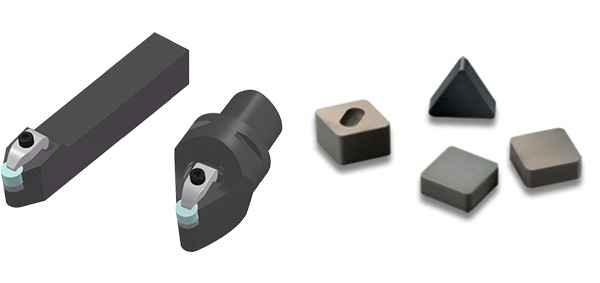

In view of the above processing difficulties, Halnn Superhard provides a variety of cutting inserts of carbide/ceramic/CBN (cubic boron nitride) to cope with different materials and high-temperature alloy materials under different working conditions.

Halnn Superhard Carbide Cutting inserts: It adopts ultra-fine particles with very high hardness, and with the blessing of special nano-level coating, it has high thermal hardness, and can maintain good cutting performance and good inserts life during cutting. At the same time, the good adhesion strength between the coating and the substrate realizes stable cutting and avoids the groove wear that is easy to occur in the processing of high-temperature alloys.

Halnn super-hard ceramic cutting inserts: whisker-toughened ceramic blades with excellent chemical stability and toughness. They can adopt higher cutting speeds and cutting depths to improve production efficiency and metal removal rate. Common grades include S100, S200, SH100, and SH200. S100/S200 are used for finishing processes, and coating services can also be provided. SH100/SH200 are used for roughing and milling processes.

Halnn superhard CBN (cubic boron nitride)inserts: The hardness is second only to diamond inserts. It has excellent high-temperature red hardness, good wear resistance and fracture resistance. It can achieve high-speed cutting, greatly improve production efficiency, and meet excellent processing effects. At the same time, it can be customized according to customer needs. Common brands include BN-S200, BDN80 and other materials.

Case study of Halnn superhard cubic boron nitride cuttinginserts BN-S200 processing nickel-based high temperature alloy

Machining object material: nickel-based alloy Inconel 718;

Hardness of processed nickel-based alloy: HRC45-HRC47 (precipitation hardened nickel-based alloy);

inserts material brand: BN-S200 round CBN blade RGN120400;

Processing process: finishing;

Cutting speed: 350 m/min;

Feed rate: 0.15 mm/rev per revolution (under this parameter, the surface roughness of nickel-based alloy after finishing is Ra0.3-Ra0.4);

Cutting depth (single-side back cutting amount): 0.5 mm.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.