PCBN and PCD inserts are widely used in various high-precision and high-efficiency processing occasions due to their high hardness, high wear resistance and long life. However, some inserts are expensive, especially non-standard customized PCD forming inserts. Directly scrapping them after use will greatly increase the cost. In order to better reuse them, Halnn launched PCBN/PCD insert grinding and replacement services. Good grinding/replacement services can effectively extend the service life of inserts and help customers reduce costs and increase efficiency.

Halnn Superhard can provide grinding/insert replacement services for the following cutting inserts

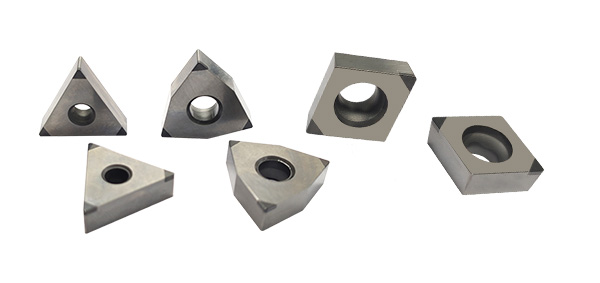

1.CBN composite insert

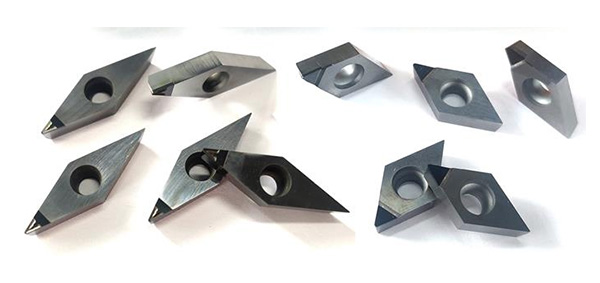

2.PCD turning inserts/milling inserts

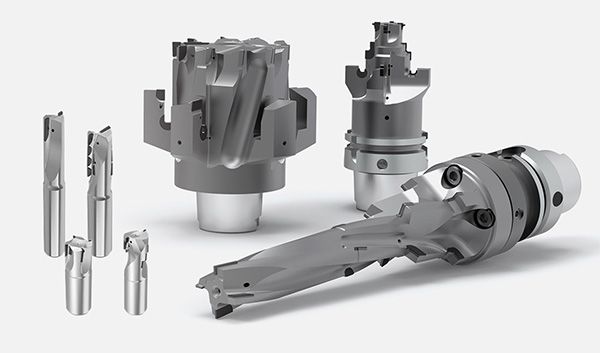

3.PCD milling cutter

4.PCD drill bit

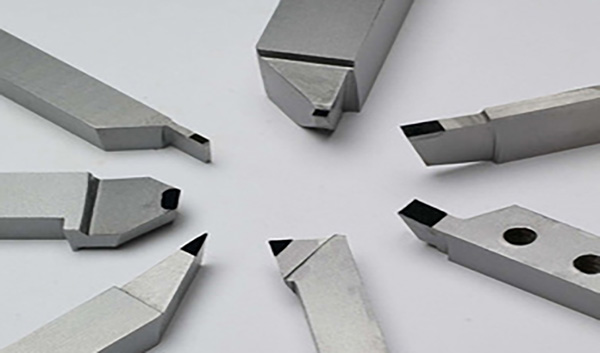

5.PCD forming tool

6.Other non-standard customized PCBN/PCD inserts

Among them, CBN composite inserts and PCD turning inserts/milling inserts can provide multiple re-sharpening services according to the wear conditions; PCD milling cutters and PCD drills can be re-sharpened and replaced according to the wear conditions; for more complex PCD forming inserts, Halnn Superhard recommends direct replacement of inserts, and the performance after replacement is as good as that of a new tool.

Advantages of Halnn Superhard's grinding/replacing services

Halnn Superhard Co., Ltd. has nearly 20 years of industry experience. Adhering to the principle of customer-centricity, it has set up complete grinding equipment. It has a series of advanced testing instruments, skilled grinding technicians and mature grinding standards, as well as advanced imported coating equipment. And it has a strict quality management system to ensure the consistent quality of products and services.

Common application areas of Halnn's grinding/replacing services

Automobile parts processing, aerospace structural parts processing, energy industry, bearing/gear and other industries.

Precautions for grinding and changing PCBN/PCD inserts

As a well-known enterprise in the field of superhard inserts, Halnn Superhard has been serving the world's top 500 companies and 80% of high-end manufacturing industries, and has unique insights in PCBN/PCD insert grinding/insert replacement services.

During the grinding process, it is necessary to pay attention to the following: (1) Theinsertbody and theinserthead are clean and tidy, free of foreign matter, and there must be no cracks or rust on the surface, and the insert must not have chipping; (2) The front angle and back angle after grinding remain unchanged, and the structure of theinsertitself cannot be changed; (3) After grinding, the thickness of each insert must be consistent and will not affect subsequent use; (4) After grinding, a coating process can be added to the PCBN insert to better meet the use effect.

During the insert replacement process, it is necessary to pay attention to the following: When removing the CBN/PCD sheet originally welded on the substrate, the performance of the original substrate must not be damaged. After replacing the new sheet, the radial runout of the cutting edge and the round runout of the insert end face must be within the required range to process the workpiece that meets the requirements of the drawing.

Under what circumstances is it not recommended to sharpen or replace the disc?

Not all PCBN/PCD inserts are suitable for grinding and replacement services. For example, if theinsertis severely damaged or the effective cutting edge is insufficient, grinding and replacement services cannot be performed. If the PCBN/PCD insert is in the form of normal wear failure, grinding can be used to form a new cutting edge, and then coating process can be used to achieve the performance of a new tool. If it is a failure form of collapse, specific testing instruments are required to detect whether it meets the requirements of grinding and replacement. If the matrix is not affected, the performance of a newinsertcan be achieved by replacing new sheets.

Summary: Halnn Superhard provides a variety of solutions to meet the needs of different customers. Whether it is normal wear or collapse failure, it can provide appropriate grinding and replacement services to ensure that customers can obtain the best cutting effect.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.