In modern manufacturing, spray welding technology is an important surface treatment process, which can significantly improve the wear resistance, corrosion resistance and high temperature resistance of parts. However, when turning spray welded parts, choosing the right tool is crucial. The following are some suggestions from Halnn Superhard to help you make a wise choice when processing spray welded parts.

Spray welding technology is mainly divided into two types:

Hot spray welding and cold spray welding:Thermal spray welding uses high temperature to melt alloy powder and spray it onto the surface of the workpiece to form a uniform and dense coating. Cold spray welding sprays alloy powder onto the surface of the workpiece through high-speed airflow at room temperature to form a thin coating.

When selecting inserts for turning sprayed/surfacing materials, the following factors need to be considered comprehensively:

Material properties: hardness, toughness, wear resistance and thermal conductivity.

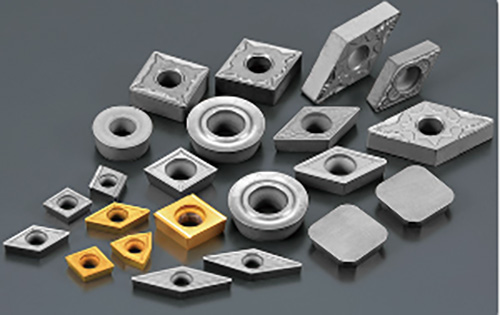

Tool material: Select appropriate tool material according to material properties, such as carbide, ceramic, CBN.

Tool geometry: Adjust the rake angle, back angle, and edge radius to optimize the cutting process.

Cutting parameters: including cutting speed, feed rate, and cutting depth, which are optimized to reduce tool wear and improve processing quality.

Advantages of Halnn Superhard BN-S20 inserts:

1. With high wear resistance, BN-S20 inserts are suitable for processing high-hardness spray-welded layers with surface hardness between HRC45-79, such as Ni60, Fe65 and Wc tungsten carbide spray-welded layers with surface hardness above HRC65.

2. Halnn Superhard BN-S20 CBN inserts, this inserts is made of CBN material, which has excellent wear resistance and impact resistance. CBN material is an advanced material that is widely used in the field of inserts manufacturing. Its unique chemical composition and crystal structure give the inserts excellent hardness and durability. Compared with traditional inserts materials such as high-speed steel or cemented carbide, BN-S20 inserts can better resist wear during cutting.

3. BN-S20 inserts have good thermal stability and can maintain stable performance in high temperature environments, which is particularly important for the processing of thermal spray-welded materials.

4. BN-S20 inserts also have a low coefficient of friction, which helps to reduce heat generation during cutting, thereby reducing the risk of thermal deformation of the workpiece. At the same time, the lower friction coefficient also helps to increase the cutting speed and further improve the processing efficiency. In addition, the chemical stability of the BN-S20inserts is also very good. It will not react chemically with the processed material, thus ensuring the processing quality and improving the work efficiency.

Summary: CBN insert BN-S20 has many advantages in processing thermal spray materials, which makes it an ideal choice for thermal spray material processing.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.