In the early years, PCD inserts only had the front corner and the clearance corner, but due to the continuous dumpling of materials such as non -ferrous metal, such as aluminum, copper and other materials, problems such as Dandruff, scratching workpiece often occur. And it has a direct impact on the life of the tool.

Halnn superhard adopts precision laser processing technology, adds chipbreaker to the PCD cutting blade, improves the dchipbreaker, effectively improves the quality of processing, while increasing the cutting speed of the cutting, it improves production efficiency. Parts identification and automatic capture of the production line.

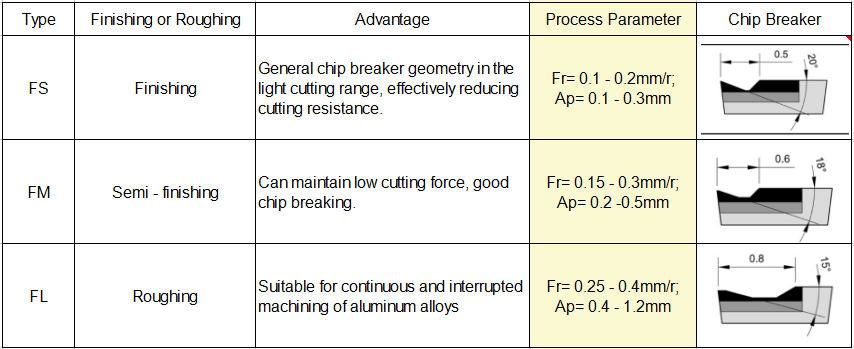

Halnn superhard frequently interrupted the following three models, and can be customized according to customer needs.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.