Gear, as a very widely used parts in the field of mechanical, often works under the condition that high speed, high load, Even speed and load are constantly changing. In order to ensure the quality and service life of its products, heat treatment is often used to obtain its excellent performance.

Gear high hardness, difficulty processing, gears are processed end facing or internal holes, and there are intermittent cutting conditions, after heat treatment, deformation of big size gear is large .which brings great trouble to the machining

In particular, the cutting conditions is interrupted . After heat treatment, the gear needs to process end facing and inner holes. When there are bolt holes or oil holes in the inner holes , they have higher requirements for the anti -fracture toughness and anti -collapse performance of the insert.

Halnn superhard, domestic superhard tools pioneer, early undertaking and completing the national key "industry -university -research" project and CBN products technology research projects, enjoying a high reputation in the superhard tools .especially " "turning insead of grinding", heavy cutting for high hardness material, cast iron high -speed processing and other segments are unique.

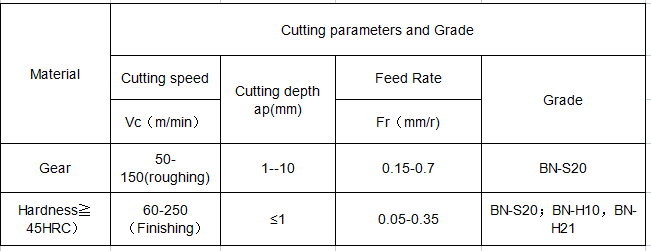

In response to hardened gear, Halnn has launched PCBN inserts BN-H10, BN-H21 , and solid CBN inserts BN-S20 for continuous and interrupted. The advantages in the field of hard processing are obvious. The cut parameters are as follows:

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.