Wind power bearing processing characteristics

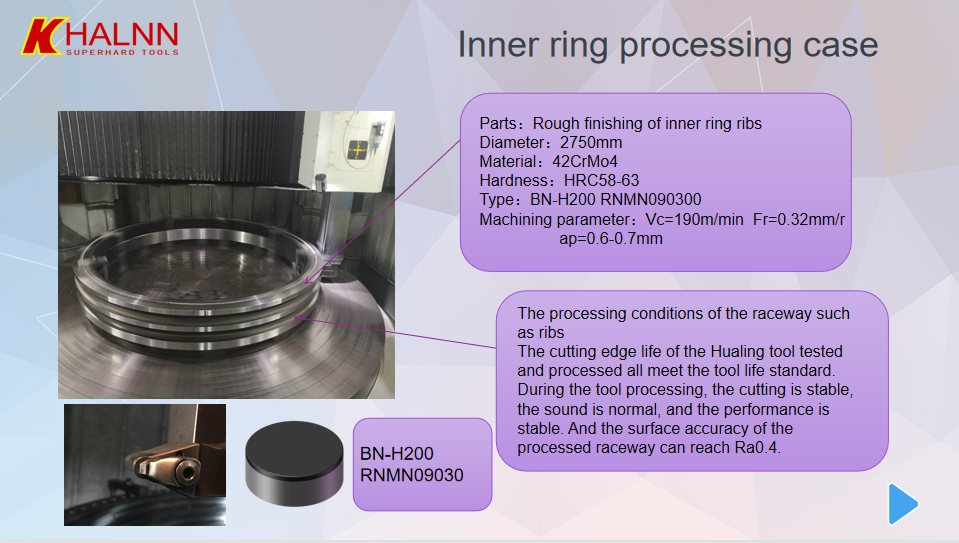

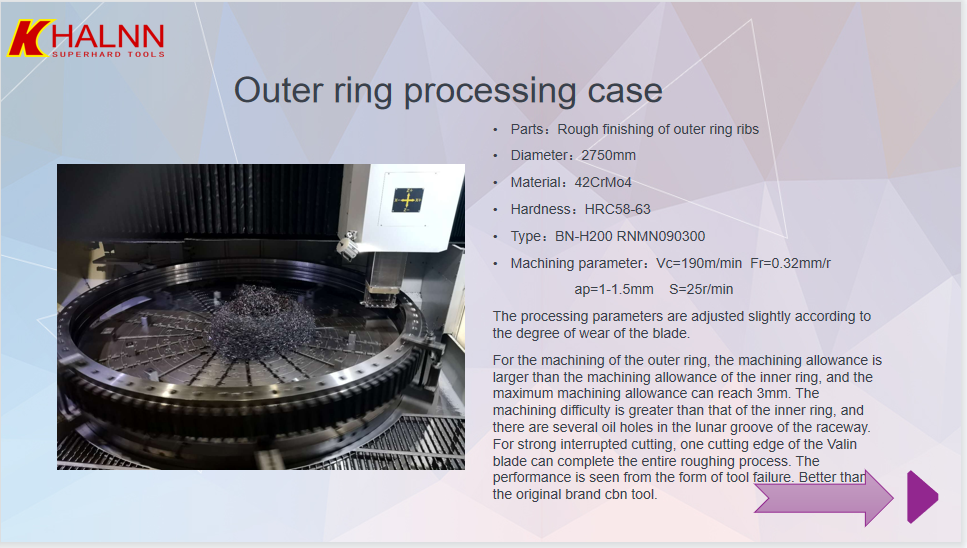

Common materials for wind power bearings are 50Mn and 42CrMo. The hardness after quenching is above HRC50, and the machining allowance after heat treatment is 2-6mm. The material of the wind power bearing tested this time is 42CrMo4.

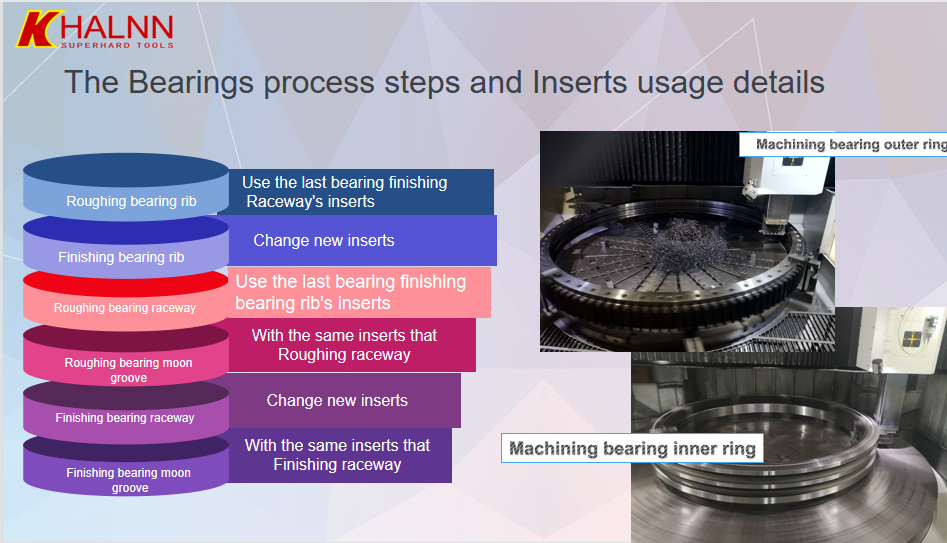

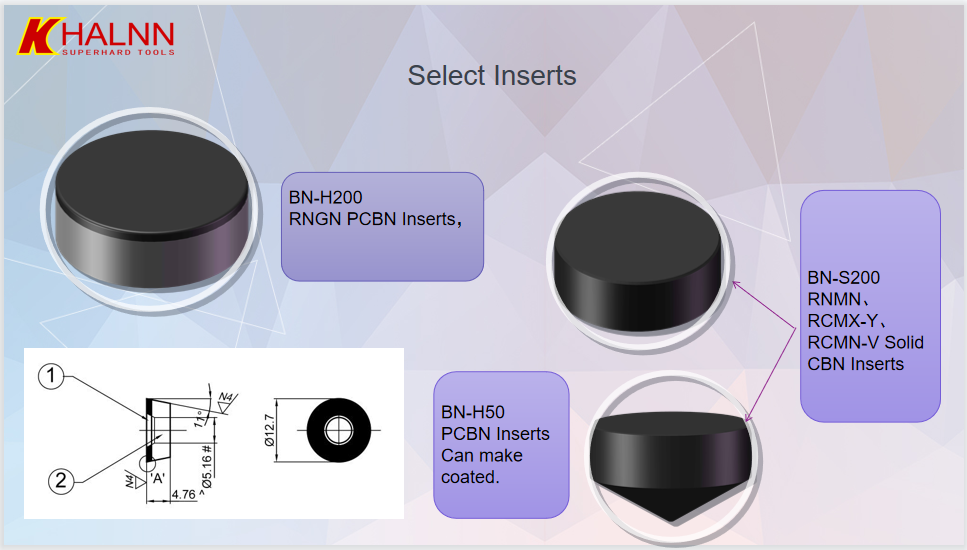

Wind power bearings are difficult to machining after heat-treated. Grinding is often used as the final processing step. However, with the development of the modern Inserts industry, a CBN Inserts material that can be ground on the Turning—CBN has been developed Insert. The last processing step of this processing of wind power bearing processing uses Halnn CBN inserts BN-H200 instead of grinding processing, which not only improves the processing efficiency, but also reduces the processing cost.

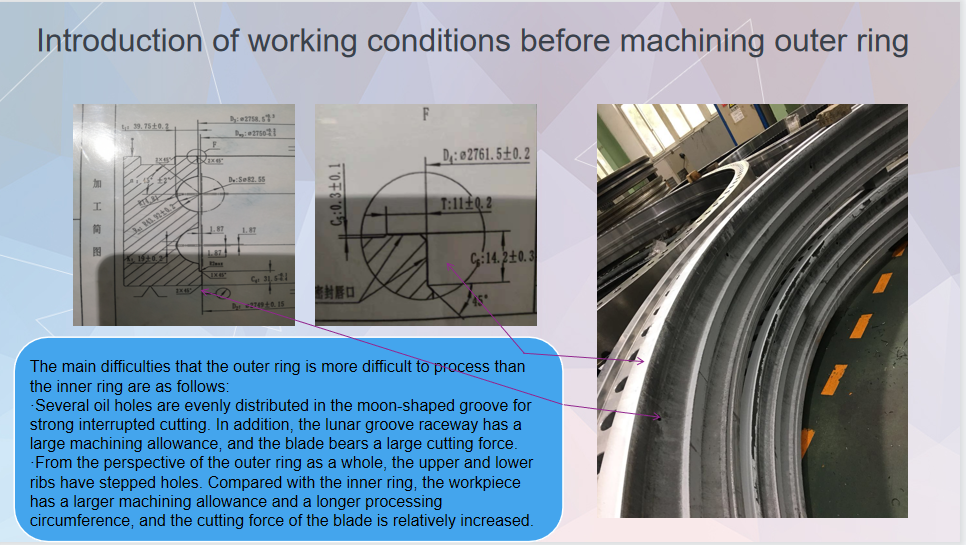

When machining the outer ring of a wind turbine bearing, intermittent cuts are formed due to oil holes in the moon groove of the outer ring raceway, and the machining allowance at the moon groove is higher than the machining allowance of the raceway and the inner hole flange Therefore, the machining performance of the CBN Inserts is more important.

For wind power bearings, the accuracy tolerance of the raceway radian is 0.08, and the surface roughness of the raceway is Ra0.4.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.