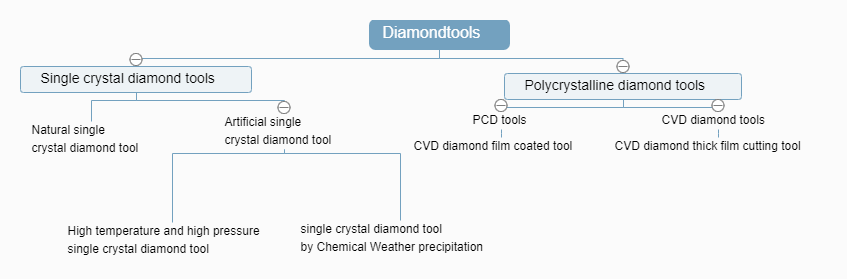

Single crystal tool is a kind of tool made of single crystal material, it is a special type of diamond tool, it has the following characteristics:

At present, single crystal diamond tool is the main cutting tool in the field of ultra-precision machining. Its cutting tool mass is generally more than 0.1g, and the minimum diameter length is not less than 2mm. It can realize mirror machining, and can produce very high workpiece precision and low surface roughness. The cutting effect is very bright, and it is recognized as an ideal ultra-precision machining tool.There are both natural and man-made single crystal diamond. The number of natural single crystal diamond is small and the price is expensive. In order to alleviate a large number of industrial demand, scientists are looking for artificial methods to synthesize diamond.Artificial single crystal diamond has the same structure and comparable performance as natural single crystal diamond, and its cost is lower than natural diamond, so it has a wide range of industrial applications and commercial prospects.

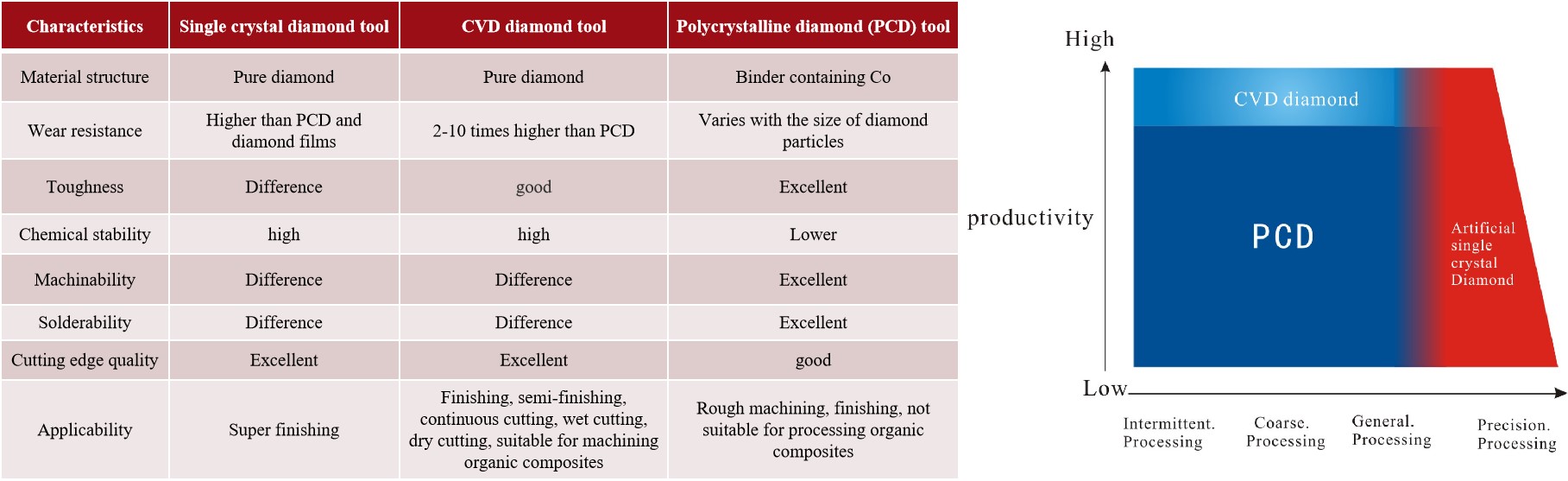

Single crystal diamond tools, polycrystalline PCD tools and CVD diamond tools are three kinds of common superhard tools materials, which have some differences in preparation process, performance characteristics and applications.

Single crystal diamond cutting tools:

Single crystal diamond tools are made of pure diamond single crystals synthesized at high temperature and high pressure. It has the following characteristics:

High hardness: single crystal diamond has very high hardness and is the hardest material known so far.

Excellent cutting performance: single crystal diamond tools perform well in machining hard materials with high cutting speed and cutting quality.

Expensive: due to the difficulty of preparation and high production cost, the price of single crystal diamond tools is high.

Application limitation: due to the structural characteristics of single crystal diamond, its scope of application is limited, and it is mainly used for processing non-iron-based materials.

Polycrystalline PCD tools are made of diamond particles and metal binders by high temperature and high pressure sintering. It has the following characteristics:

High hardness: the hardness of polycrystalline PCD tool is higher than that of most materials, but slightly lower than that of single crystal diamond.

Good cutting performance: polycrystalline PCD tools have excellent performance in machining metal and non-metallic materials, and the cutting speed is fast.

Lower cost: compared with single crystal diamond tools, the preparation process of polycrystalline PCD tools is mature and the production cost is relatively low.

A wide range of applications: polycrystalline PCD tools can be used for machining a variety of materials, including iron-based materials and non-iron-based materials.

CVD diamond tool is a diamond film synthesized on tools substrate by CVD. It has the following characteristics:

Film structure: the diamond layer of CVD diamond tool is a thin film rather than a whole block, so its hardness is slightly lower than that of single crystal diamond and polycrystalline PCD.

Good cutting performance: CVD diamond tool has good cutting performance when machining hard materials, but it is slightly inferior to single crystal diamond tool and polycrystal PCD tool.

Strong customizability: CVD technology can realize the customization of diamond films, and the structure and thickness of diamond films can be designed according to specific requirements.

Wide range of applications: CVD diamond tools can be used to process a variety of materials, including metallic and non-metallic materials.

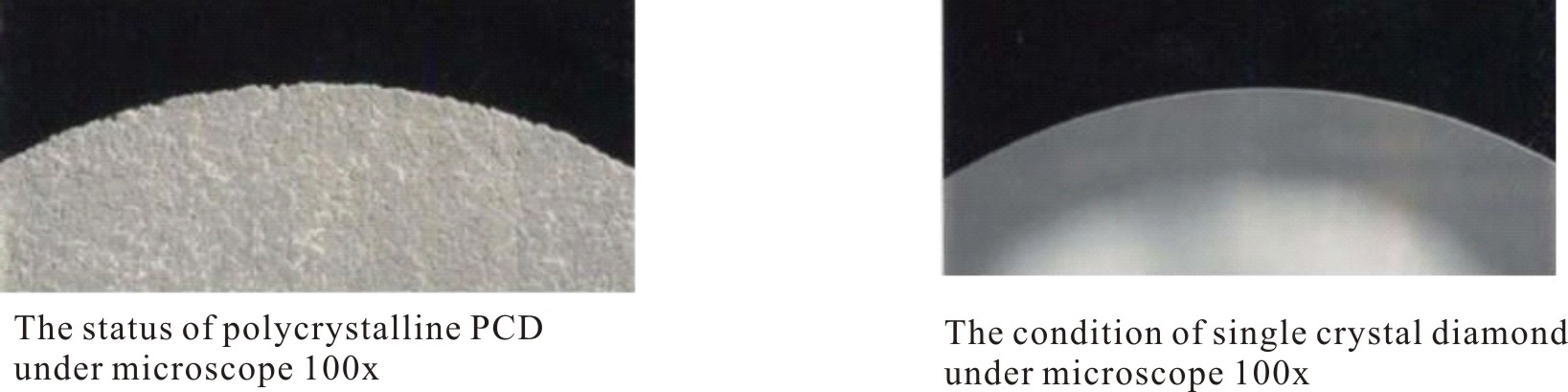

The condition under the microscope:

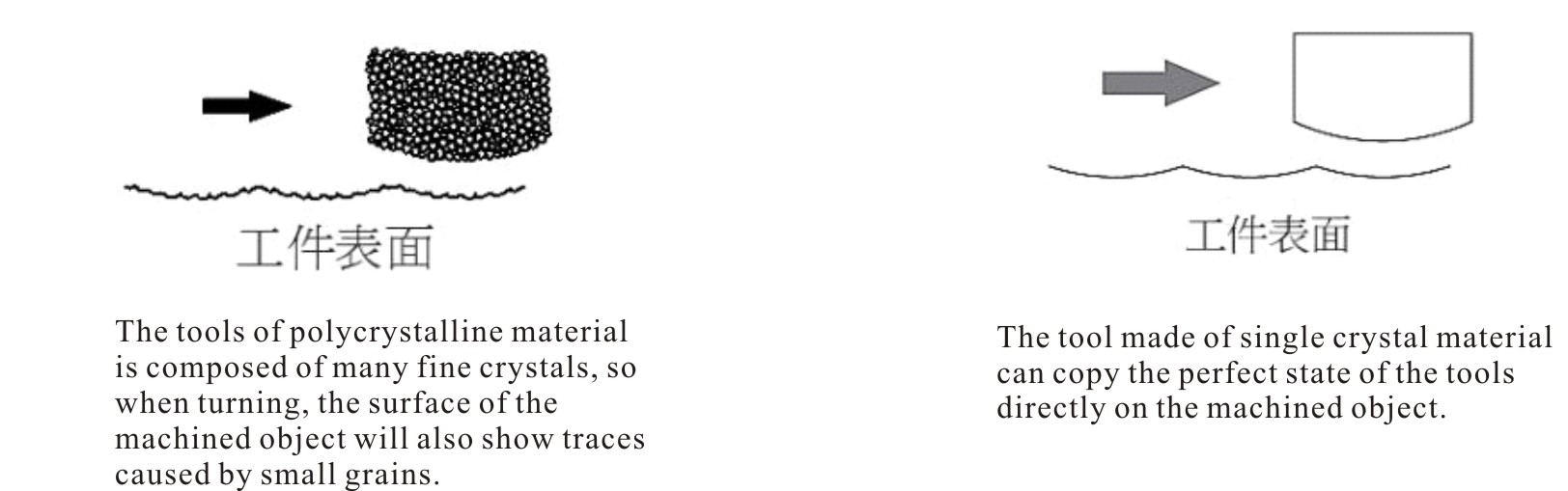

Differences in processing:

In the sophisticated world of contact lens manufacturing, the single crystal tools has become an indispensable tool. With the excellent cutting performance and precision of the single crystal tools, we are able to create amazing contact lens products. Through the precise cutting of a Single Crystal Diamond tools for Contact Lenses and IOL’s, we are able to achieve the accuracy and fit of the contact lens. In addition, the Single Crystal Diamond tools for Contact Lenses and IOL’s has excellent cutting quality, ensuring the smoothness and transparency of the contact lens surface.

The waviness of Halnn Single Crystal Diamond tools for Contact Lenses and IOL’s is less than 100nm, the finish is less than 10nm, and the minimum arc radius can reach 0.001mm, which has the following characteristics and advantages:

Extremely high hardness: Halnn Single Crystal Diamond tools for Contact Lenses and IOL’s have higher hardness than CBN and other materials. It can withstand high pressure and wear, maintaining the sharpness and stability of the tools

Excellent wear resistance: Halnn Single Crystal Diamond tools for Contact Lenses and IOL’s have excellent wear resistance and can maintain a long service life in high-speed cutting and high temperature environments. It can withstand the high temperature, high pressure and chemical reaction of metal materials, and is not easy to wear or degrade.

High cutting efficiency: Halnn Single Crystal Diamond tools for Contact Lenses and IOL’s can provide efficient cutting efficiency in cutting because of its extremely high hardness. It can realize high speed cutting, high feed rate and large cutting depth, reduce machining time and improve production efficiency.

High precision machining: Halnn Single Crystal Diamond tools for Contact Lenses and IOL’s can achieve high precision machining, maintain small tolerances and high surface quality. It can remove defects and defects on the material surface and provide a smooth and smooth machined surface.

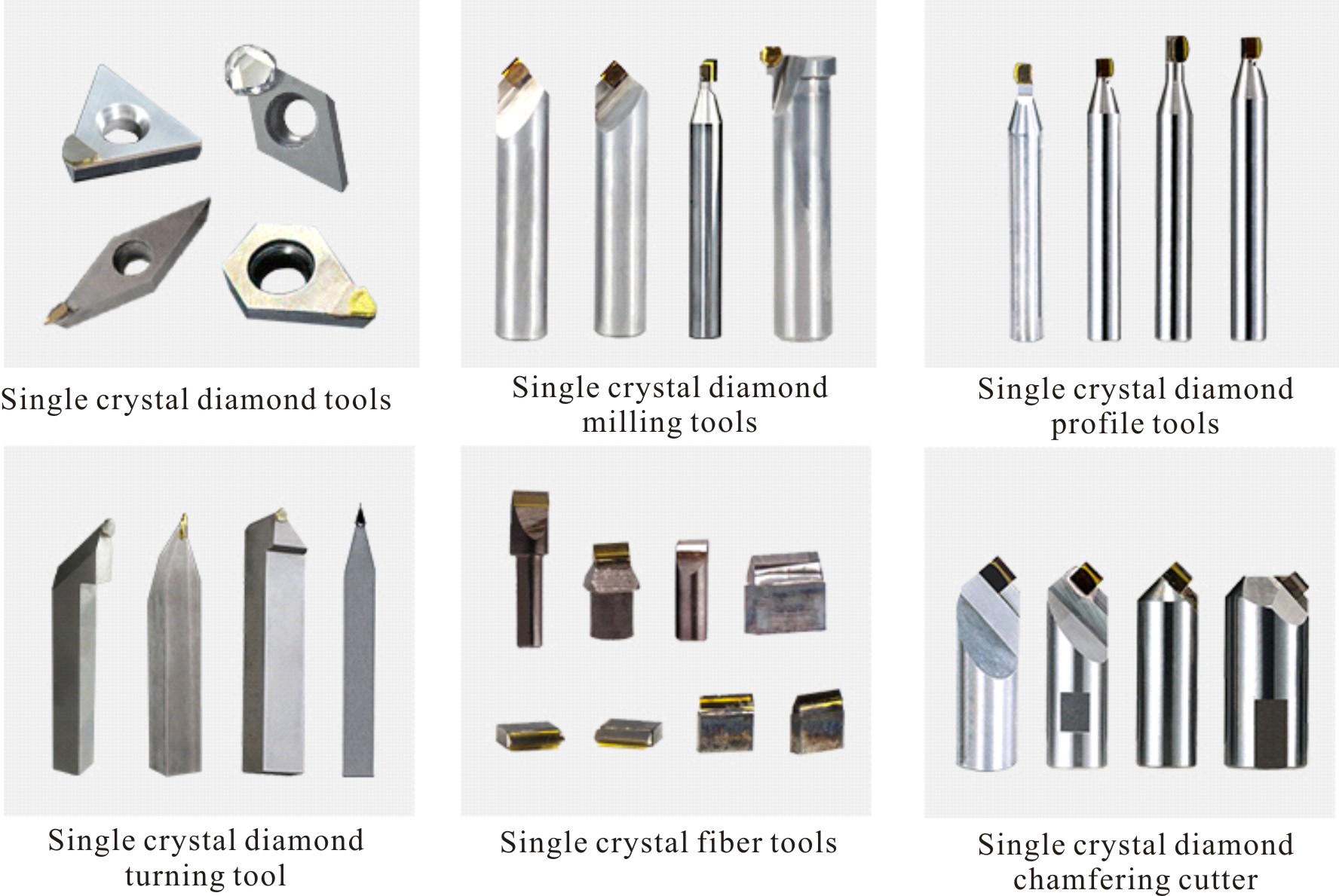

Suitable for hard materials processing: Halnn Single Crystal Diamond tools for Contact Lenses and IOL’s are especially suitable for machining hard materials, such as cemented carbide, ceramics, glass and so on. It can effectively cut these materials and achieve high precision and high efficiency. Suitable tool types: optical fiber single crystal tools, single crystal diamond tools, single crystal diamond turning tool, milling tools, profile tools, chamfering tools, slotting tools and so on.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.