Diamond burnishing tools, is a kind of rolling tool specially used for high hardness materials, which has a breakthrough ability, so that the rolling processing of high hardness materials is no longer a difficult problem.

First, the characteristics of Diamond burnishing tools:

High hardness materials: Diamond burnishing tools uses diamond as tool material. Diamond has extremely high hardness and can effectively roll and process high hardness materials, such as ceramics,carbide and so on.

High precision and finish: Diamond burnishing tools can realize high precision and smooth polishing, make the machined surface smooth and smooth, and reduce surface roughness and defects.

Long life and stability: Diamond has excellent wear resistance and corrosion resistance, so that the Diamond burnishing tools has a long life and stable performance, and can maintain high-quality machining effect in continuous polishing.

Widely used: Diamond burnishing tools is widely used in precision machining fields, especially in optics, semiconductors, ceramics and carbide industries, for polishing the surface of parts, such as lenses, lenses, mould and so on.

When using Diamond burnishing tools, it is necessary to select appropriate tool size, rotational speed and machining parameters according to specific materials and machining requirements to ensure the quality and consistency of polishing effect.

Zhengzhou Halnn Diamond burnishing tools expands the application range of polishing technology, which can polish workpieces with the highest hardness up to HRC65, and is suitable for machining small diameter and thin-walled workpieces.

Halnn Diamond burnishing tools is molded by a coming shape gold measuring stone fixed on the tool body to squeeze the workpiece surface. If the force exceeds the material service point, the landscape bulge on the workpiece surface will flow into the depression of the phase in μm units. Because the contact area between the workpiece and diamond is very small, the intuitive cold forming operation can be carried out in the case of less force.

Second, the technical advantages of Halnn Diamond burnishing tools:

The spherical diamond slides across the workpiece surface under spring loading, resulting in a smooth hardened surface and ensuring that the accuracy and tolerances of the workpiece are not damaged.

Diamond burnishing tools can process small diameter parts or thin-walled parts.

Workpieces with hardness greater than HRC60 can be machined.

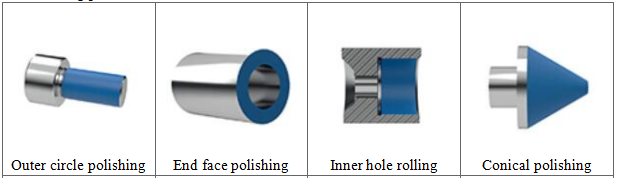

Because of the point contact between the diamond and the workpiece surface, the end face can be used for machining various shapes, such as outer circle, inner hole and Diamond burnishing tools, which is very economical and can be used for ordinary machine tools without additional equipment.

It can process very small conical surfaces with a minimum machining diameter of 0.1mm.

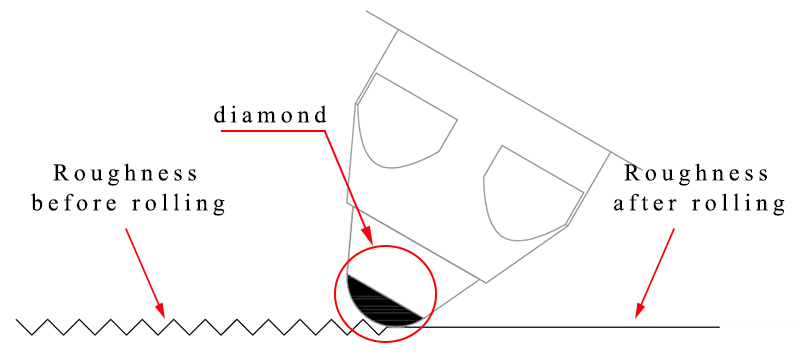

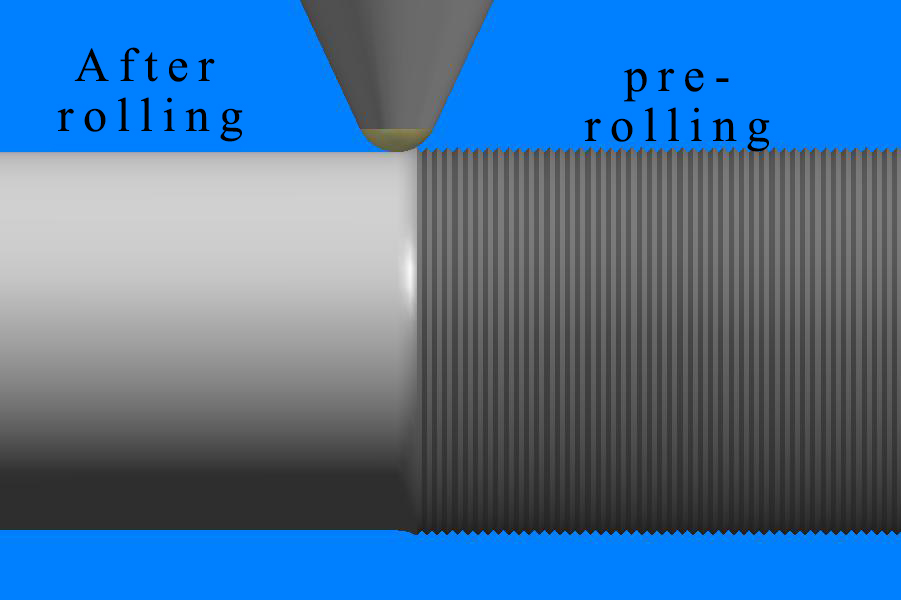

Principle of diamond rolling:

Under the microscope: the tool tip of the workpiece will remain on the surface like a step in the process of cutting, and the diamond will overcome the yield point of the material in the process of sliding on the workpiece surface under the action of spring force, resulting in plastic deformation on the material surface. force the highest point of the cutting trace to flow into the lowest point, thus a flat and smooth mirror can be obtained. In the process of rolling, the material will produce hardening treatment due to plastic deformation, so as to improve the fatigue strength of the workpiece surface. In order to achieve the best extrusion effect, the surface finish of the last cutting process of the workpiece should be about 80 to 100R.M.S.

Third, the application field of Halnn Diamond burnishing tools:

1. Suitable processing materials: all plastic deformed metals such as steel, cast iron, brass and so on can be polished. The conventional steel roller polishing tools can process materials with hardness below HRC45, and the highest hardness of Diamond burnishing tools can reach more than HRC60.

2. Processing parts: outer circle, end face, inner hole, cone, arc, etc.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.