Halnn tools’unique advantaged field- the mill rolls industry:

Mill roll is a key accessory for a steel mill. The speed of rolling mill depends on the hardness of mill rolls. (The harder the mill rolls are, the faster the rolling speed will be.)

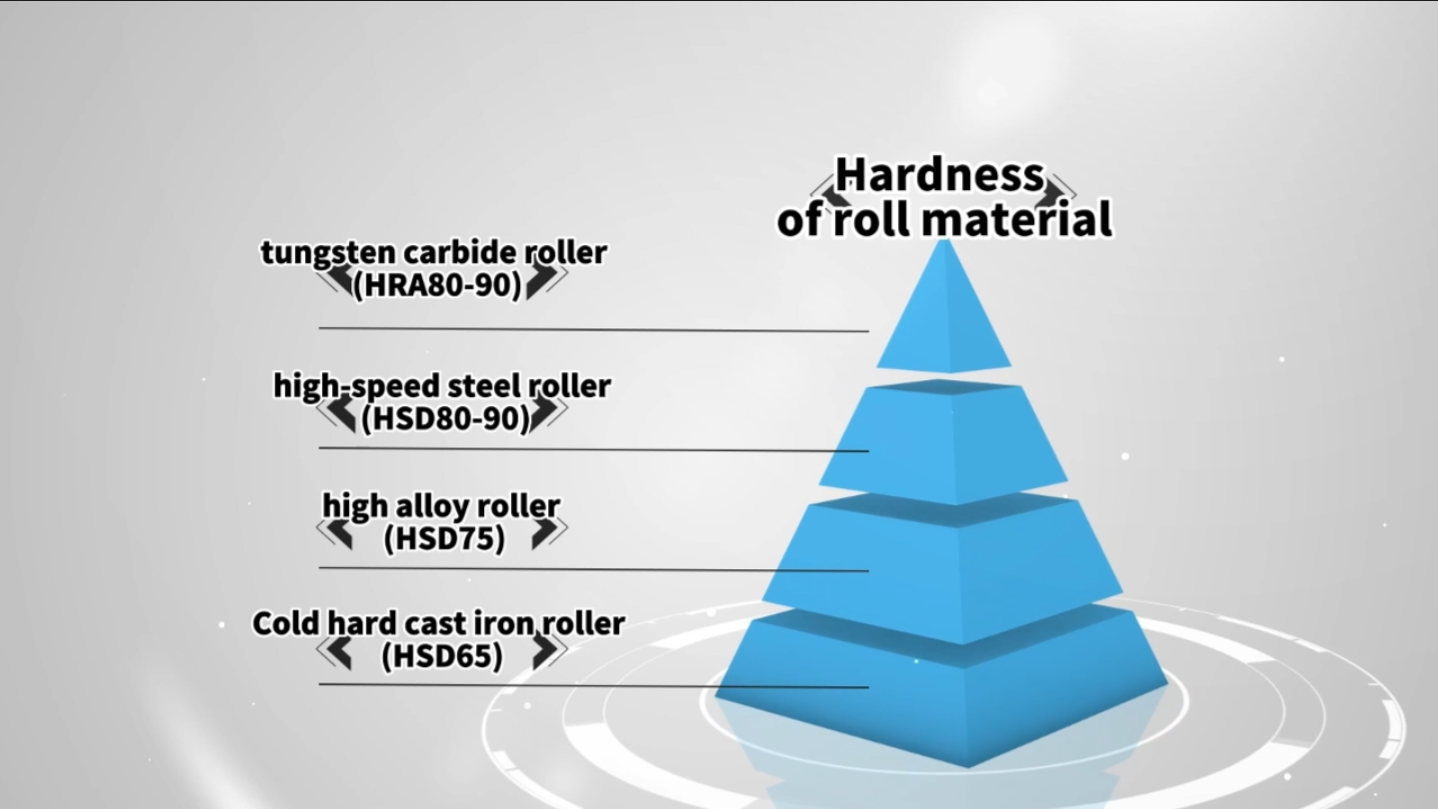

From the perspective of materials, here are the major types of rollers (the hardness is from low to high):

Cold hard cast iron roller (HSD65), high alloy roller (HSD75), high-speed steel roller (HSD80-90), tungsten carbide roller (HRA80-90).

They are all difficult-to-machine materials.

Halnn tools materials include hard alloy, carbide inserts, ceramic inserts, CBN inserts, PCD inserts(the hardness and wear resistance of them increase sequentially).

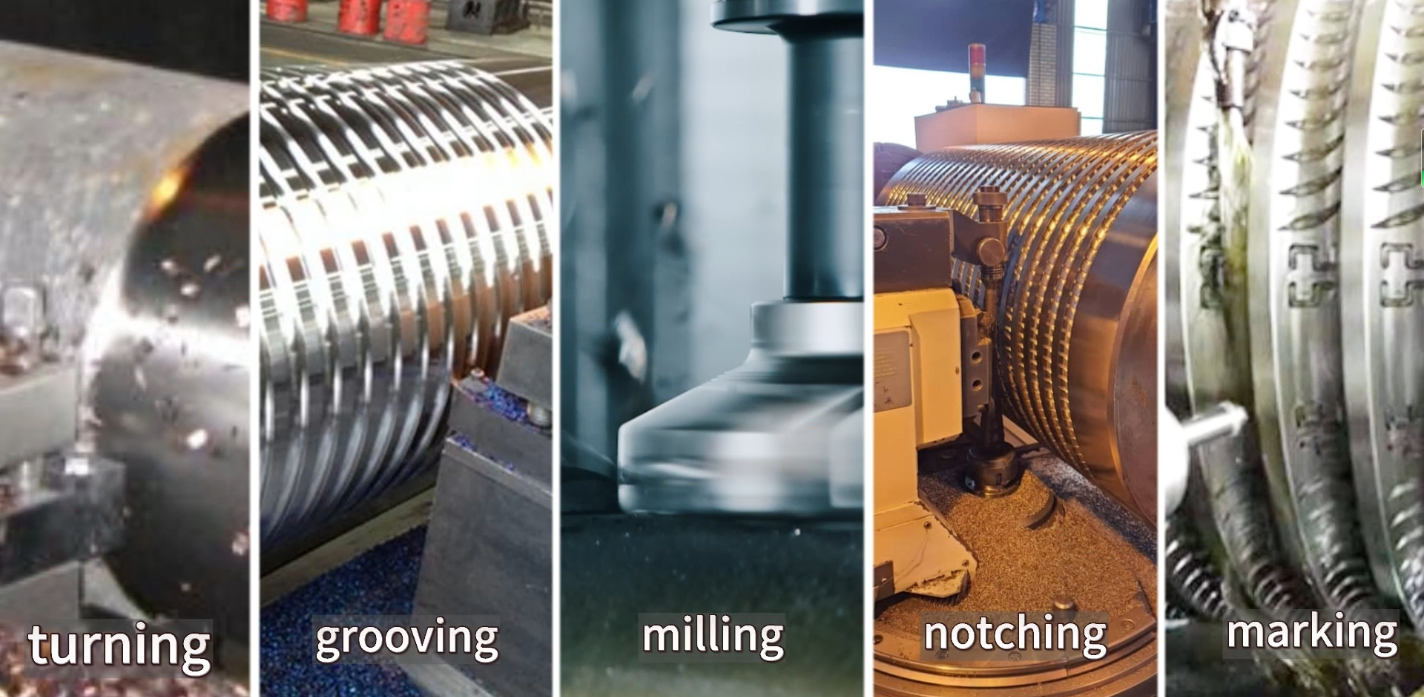

The types of Halnn tools include: turning, grooving, milling, notching and marking. We also have machine tool accessories such as holders and spindles.

At the same time, there arecorresponding tool customization in the field of roller repair/reprocessing.

The field of mill roll industry is what every Halnn man is proud of. We provide various processing tools for hundreds of steel mill workshops.

Here, let me show you some cases from Halnn.

In this case, we can find the difficulties of processing: 1. The hardness is HSD80, and the cutting depth is 9 millimeters; 2. The workpiece is very large, the length is 4,200 millimeters, the diameter is 700 millimeters. 3. the workpieces surface have casting iron scab flaw.

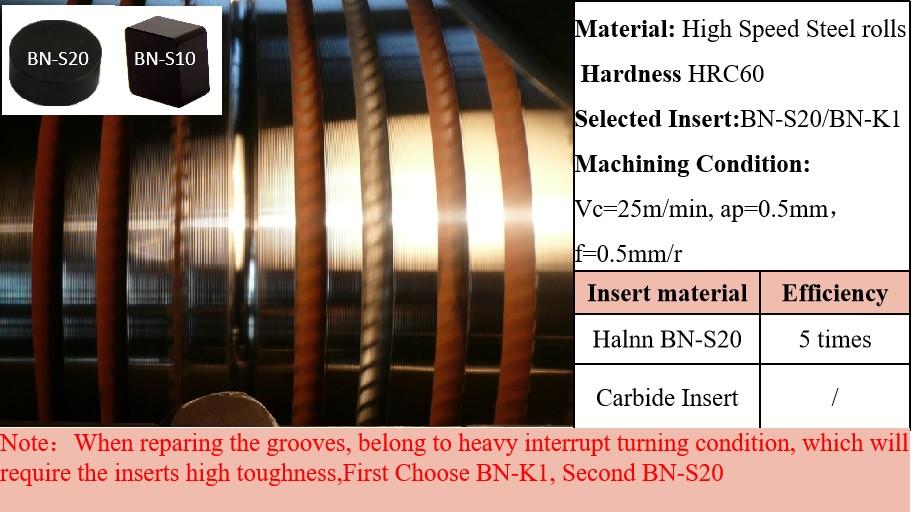

In the next case, the fracture resistance/chipping resistance of Halnn CBN inserts BN-K1 will be better embodied: repairing high speed steel roller and turning to remove rebar ribs, we can find this case is heavy interrupted turning.

In this picture, we can find the different condition of the used insert. Such condition reflects good fracture resistance.

Apart from turnings, there are also cases of milling and grooving.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.