With the development of automation and intelligence in the metallurgical iron and steel industry, the requirements of rolling speed and roll material in the production and processing process are becoming higher and higher. Tungsten carbide (WC) alloy roll ring is one of the hardest metal rolls at present, which is often used in high-speed wire rod mill. Its hardness can reach HRA78-95, and the rolling speed is very fast 75m/s (75m in 1 second), up to 120~140m/s (120m ~ 140m in 1s).

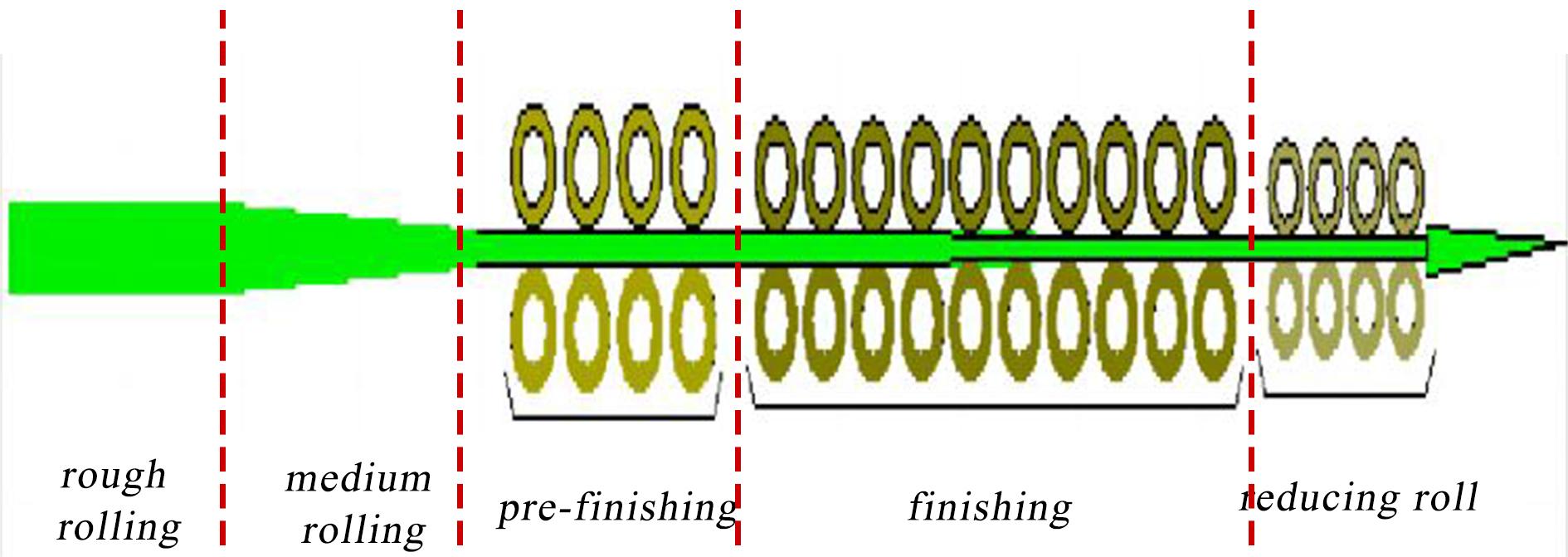

In the process of steel rolling, the roll can be divided into rough rolling stage, medium rolling stage, pre-finishing stage, finishing stage and reducing roll stage.

Junior high school rolling mills generally have 12 to 14 rolls, most of which use cast iron rolls, and the last two rolls may use tungsten carbide composite rolls. The pre-finishing mill generally has 2 to 4 rolls, most of which use tungsten carbide roll rings. The finishing mill generally has 10 rolls, all of which use tungsten carbide roll rings for micro-tension rolling.

Here are some common roll types to see how many you can recognize:

Halnn PCD notching tools, diamond engraving tools and PCBN/PCD turning inserts can be used in the machining of tungsten carbide rollers.PCD/PCBN turning tools are not necessary in the field of tungsten carbide rolls, but are generally determined according to the materials used by users and negative chamfering requirements. I repeat here: PCBN is mainly suitable for the hardness range below HRA88, while PCD can be applied to tungsten carbide rolls with any hardness.

In the case of turning tungsten carbide rolls, Halnn's BN-S300 solid CBN tool can be selected for rough machining, but it is only recommended for tungsten carbide rollers below HRA88. For other cases, it is recommended to choose the composite PCD tool for machining, because the hardness of the composite PCD tool is higher than that of the PCBN tool and the service life is longer.

During the repair of tungsten carbide roll rings, BN-S300 round inserts are machined at a feed speed of Fr=1mm/r (1 mm per turn), which is the only CBN grade suitable for roughing tungsten carbide rolls.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.