With the continuous development of industrial automation, the metallurgical steel industry has higher and higher requirements for processing efficiency and quality. Halnn PCBN inserts, to help you achieve a huge improvement in production efficiency! Let's take a look at the story of this customer.

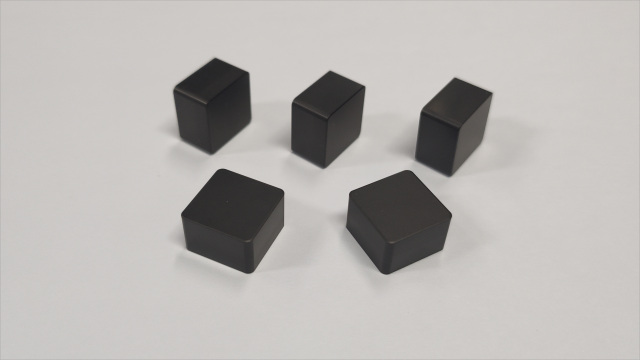

This is a company specializing in the production of metallurgical iron and steel rolls, through communication to understand that the processing roll material of the enterprise is chilled cast iron rolls, and its own hardness reaches HRC60-65 after casting, customers currently use carbide inserts SDMT120508, processing a roll takes up to 30 hours, the efficiency is too low. So they found Halnn. After analysis, Halnn tool sales engineer recommends customers to use integral PCBN Inserts HLCBN SNMN150716. At the same time, the cutting parameters are adjusted, the feed rate is increased, and its efficiency is increased by 5-10 times. Originally, a roll was processed in 30 hours, but now it only takes 6 hours to complete, and only 3 inserts edges are used to complete the production, which greatly reduces the tool change frequency and does not have tool contact marks. The surface quality is higher, the amazing effect makes the customer very satisfied!

Halnn CBN inserts make your production more efficient and intelligent! If you also want to improve processing efficiency, you might as well choose Halnn tools to open your road to industrial intelligence!

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.