Today we bring you a large collection of roll processing cases.we will show several examples of roll processing, covering different materials and different processing requirements.

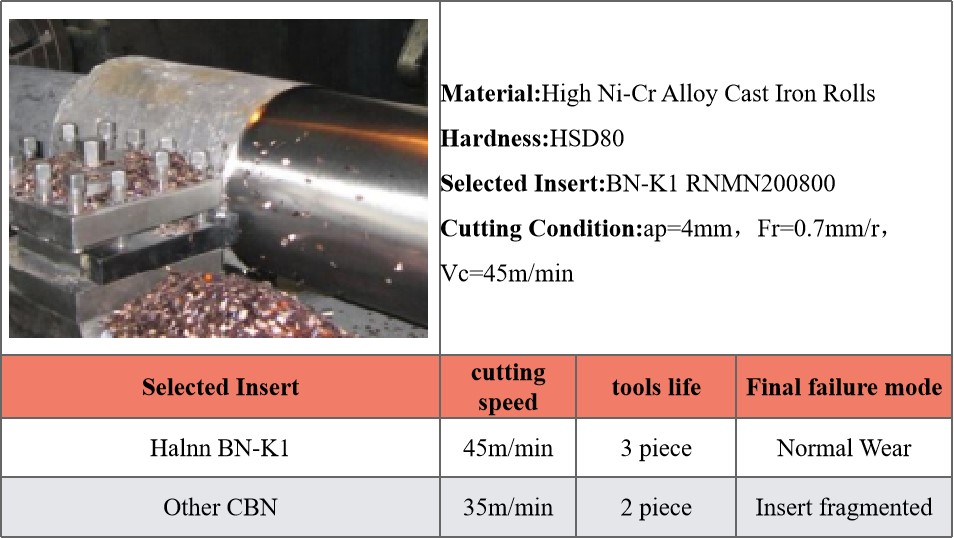

(1) High Ni-Cr Alloy Cast Iron Rolls machining: using Halnn solid CBN inserts BN-K1 grade, in the case of deep cutting 4mm, compared with a certain brand CBN inserts, the efficiency is increased by 28%, and the service life is increased by 50%.

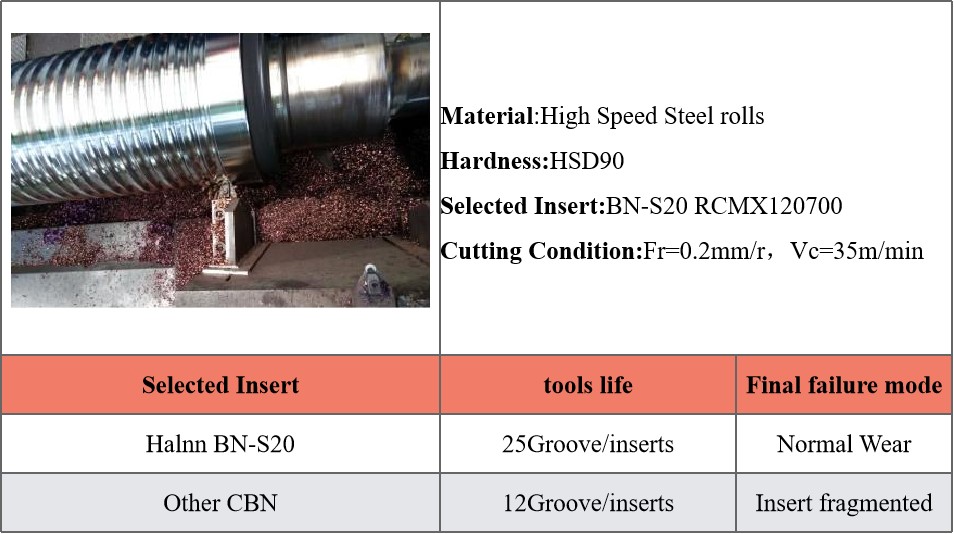

(2) High Speed Steel rolls machining: using Halnn CBN inserts BN-S20 grade, compared with a certain brand CBN inserts, the tool life of BN-S20 is twice as long as a certain brand CBN inserts under the same cutting parameters, and the final failure form is normal wear.

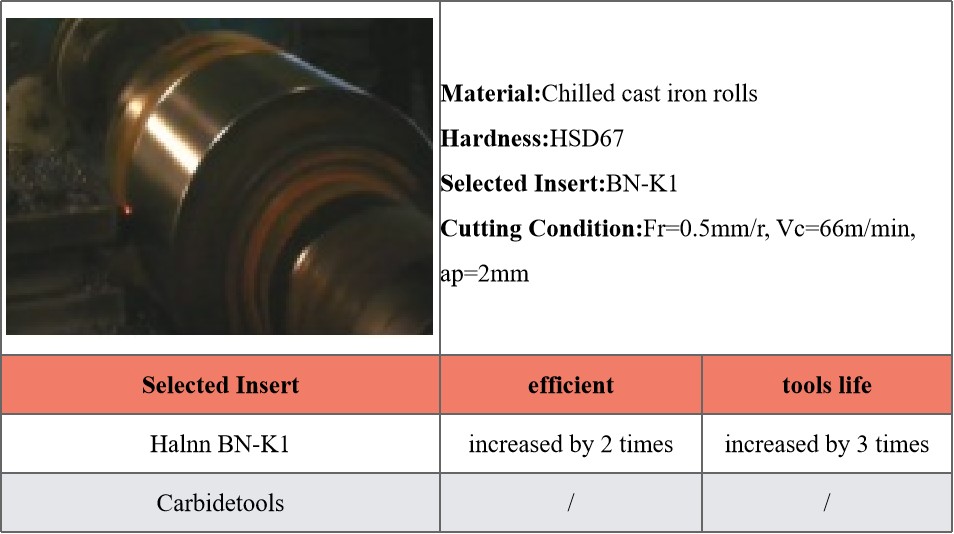

(3) Chilled cast iron rolls machining: there are hard spots and uneven surface of casting roll. Compared with traditional carbide tool, the efficiency of Halnn solid CBN inserts BN-K1 is increased by 2 times and the tool life is increased by 3 times.

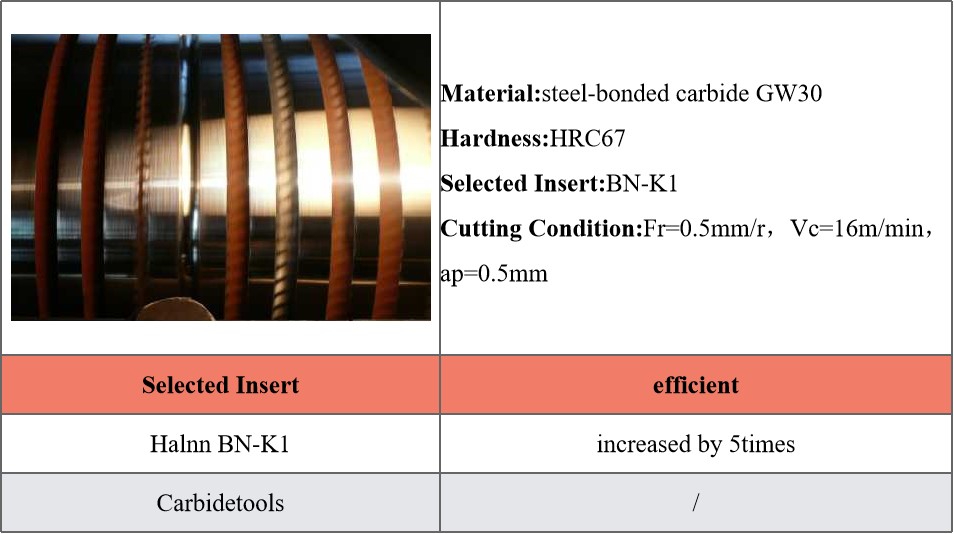

(4) Threaded steel roll repair: the steel-bonded carbide GW30 material is used, and the roll surface hardness reaches HRC67 after repair. Halnn CBN inserts BN-K1 is used for turning, which is 5 times higher than the traditional carbide tool efficiency.

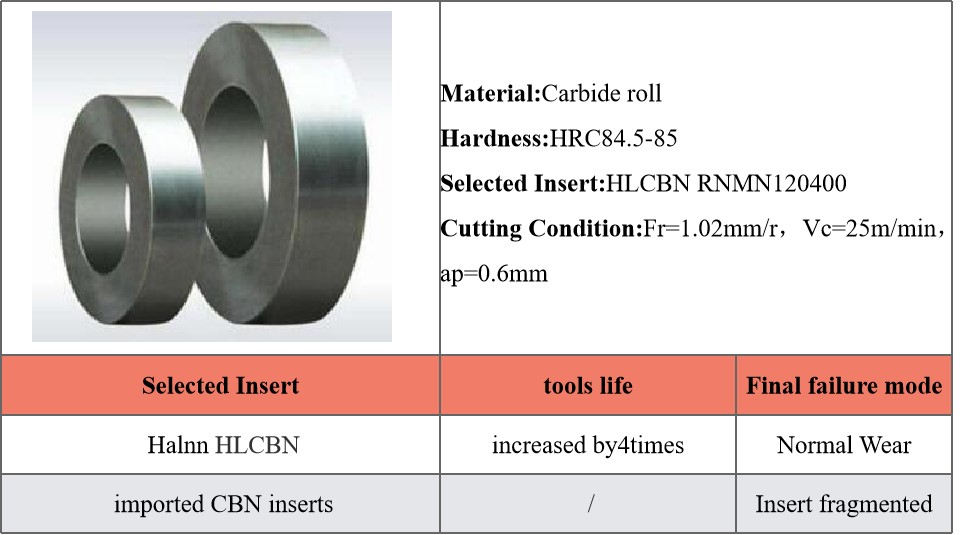

(5) carbide roll machining: carbide roll hardness HRC84.5-85, using Halnn CBN inserts HLCBN grade, the tool life is 4 times higher than that of an imported CBN inserts.

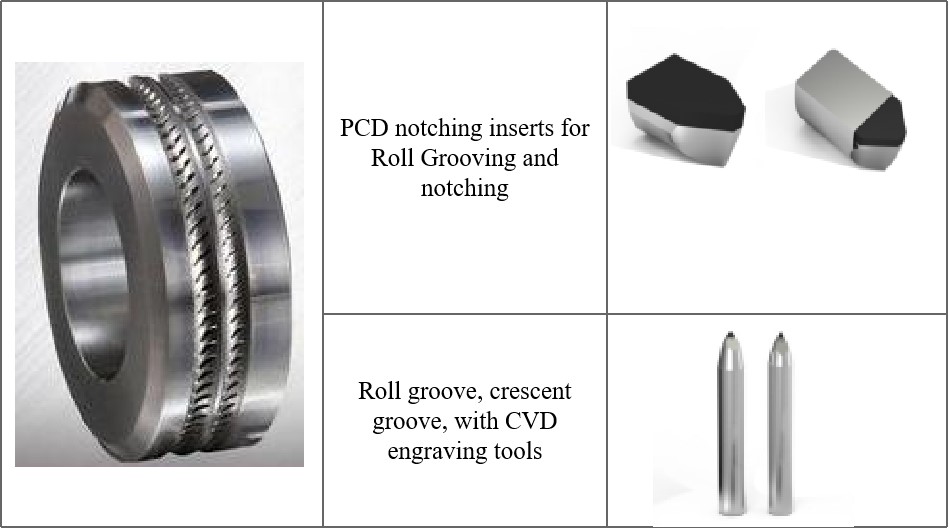

(6)Roll groove engraving and notching:Halnn can provide notching inserts made of carbide and PCD for high speed steel rolls and carbide rolls / rings, respectively. CVD diamond engraving tools is used for roll / roll ring marking.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.