With the improvement of the rolling speed, the requirement for the hardness of mill roll is higher. Now, the main materials for rebar mill rolls are high speed steel and tungsten carbide.

We can see the notching operation and engraving operation for the high-speed steel mill rolls. As for the material of these cutting tools: special tungsten carbide. They have required wear resistance and impact resistance for notching and engraving.

For the grinding process of high-speed steel mill rolls, Halnn provides CBN grinding wheels to improve the efficiency.

What cutting tools do we use for the hardest tungsten carbide roller ring? Tungsten carbide cutting tools? No! Now, we need to use CBN/PCD tools and CVD diamond tools to notch, engrave and grind such high-hardened materials.

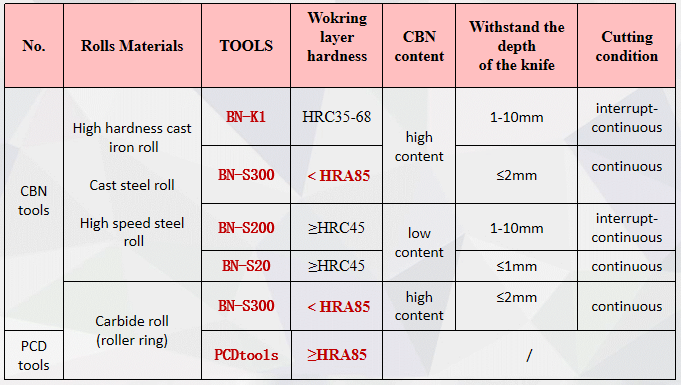

For the machining method of tungsten carbide roller rings’ surrounding ring slots, we select tools and machining process according to the hardness of the mill rolls.

First, for the tungsten carbide mill rolls whose hardness is below HRA85, Halnn use the special CBN grade BN-S300 for rough turning.

Second, for the tungsten carbide mill rolls whose hardness is above HRA85, Halnn use PCD tools for form turning.

For the final operation of the ring slots, we use diamond wheels to grind.

Finally, if you have any questions about our machining methods, such as our tool materials and parameters, machining process, machining efficiency and accuracy, please leave a message. I am sure Halnn can give you satisfactory answers and solutions.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.