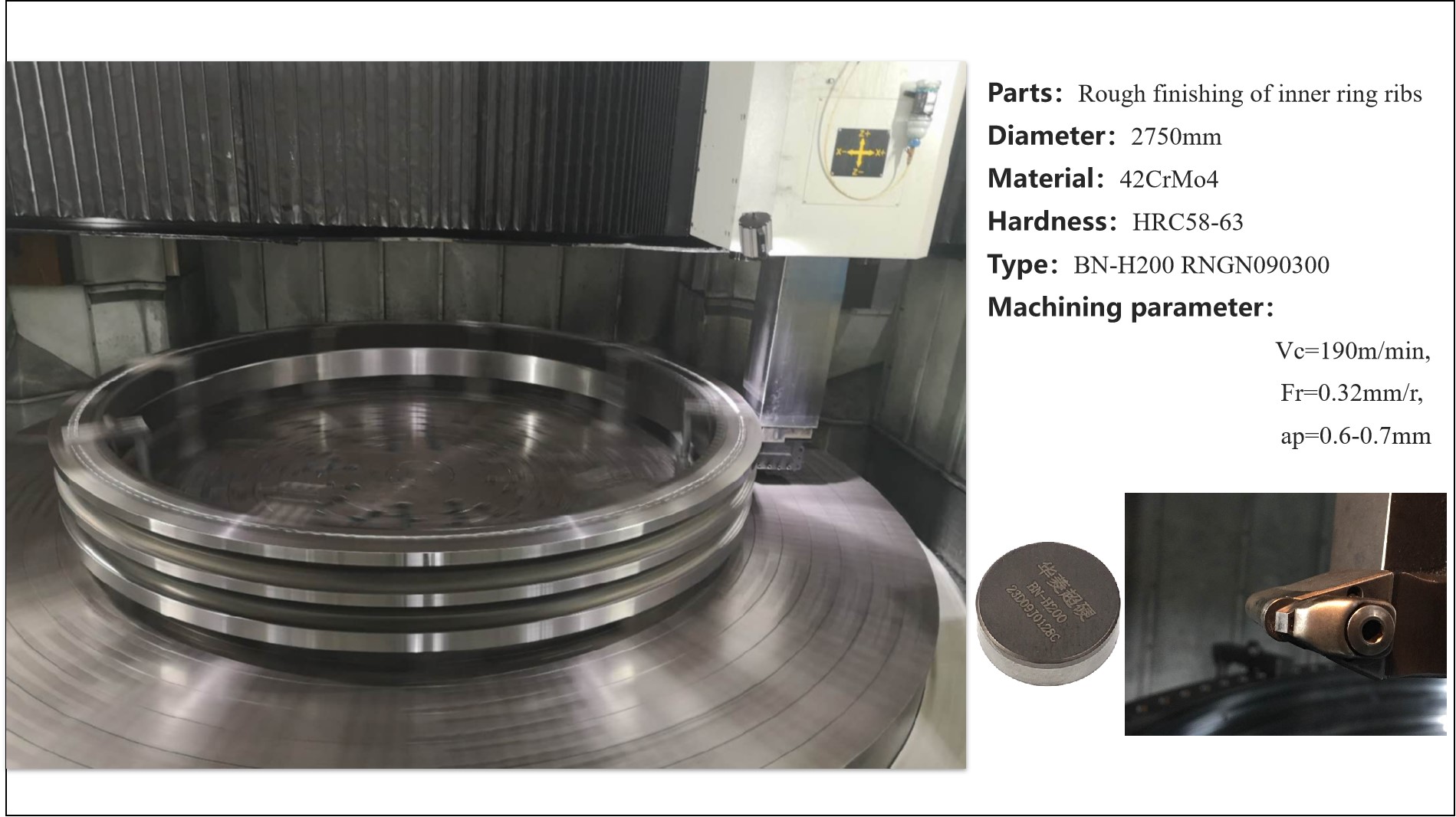

Halnn PCBN inserts provide excellent solutions for rough turning of inner ring ribs of wind turbine bearings, solving the customer's original PCBN inserts are not wear-resistant, machining super poor and other problems.

this is the case of machining the inner ring of wind power bearing. The machining part is the rough finishing of inner ring ribs. The machining diameter is up to 2750mm. The bearing is mainly made of 42CrMo4 with hardness HRC58-63. When machining the lower channel, the normal CBN inserts is not good at wear-resistant, which leading to unqualified pressure angle size, roughness and scratches on the surface. Our solution of BN-H200 RNGN090300 PCBN inserts with adjusted machining parameters and the good wear resistance, customers' pain can be easily solved.

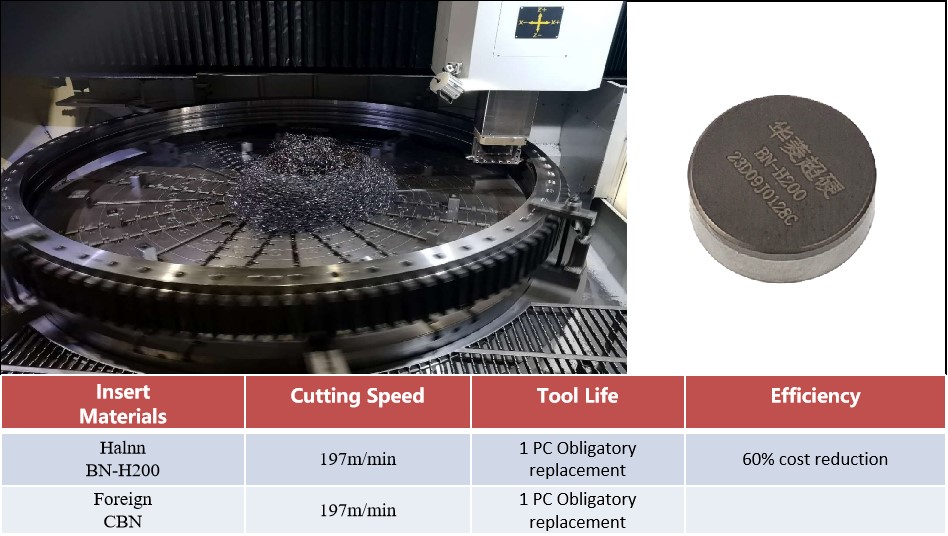

And this is a case of machining the outer ring of wind power bearing. With a diameter of 2750mm, the problem is the large cutting depth of 1-1.5mm, and the strong interrupt cutting. The normal CBN inserts are not good at wear resistance and the size tolerance. The life time is only 1 piece. Our solution is BN-H200 PCBN inserts. With high wear resistance and strong impact resistance, the cost can be reduced by 60%.

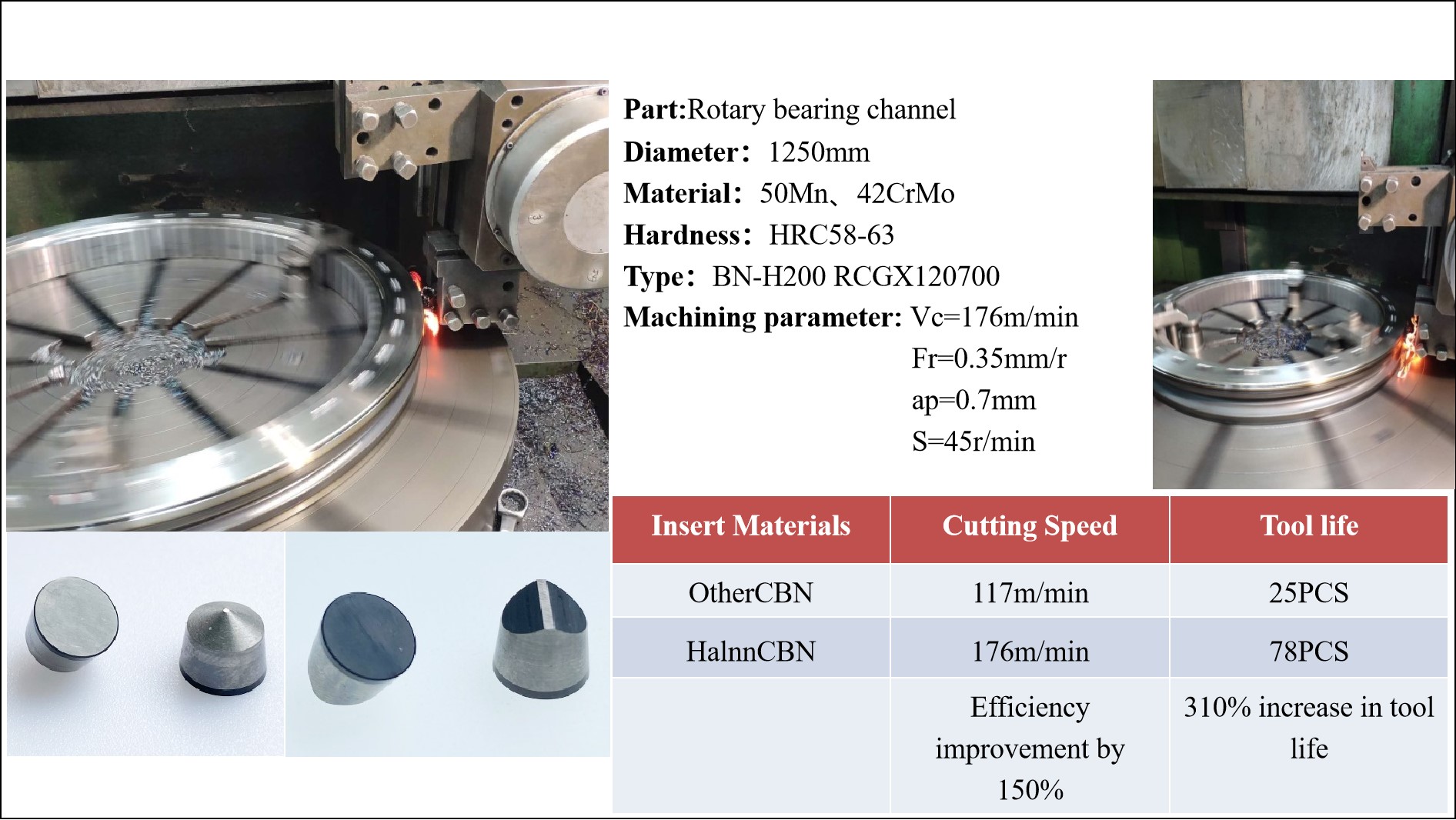

Finally, it is a case of Single slewing bearings in construction machinery. The machining part is the channel, and the size is 1250mm. The material is 50Mn and 42CrMo. The hardness is HRC58-63. The original VC was 117m/min, and the tool life was 25 pieces. With our solution of PCBN inserts BN-H200 RCGX inserts, the VC can reach 176m/min, which means the machining efficiency is increased by 50%. While the tools life is increased by 310%.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.