Halnn PCBN inserts provide excellent solutions for hard turning wind turbine gears, solving the problems of the original workpiece size, cutting wind turbine gears CBN tool broken and low machining efficiency.

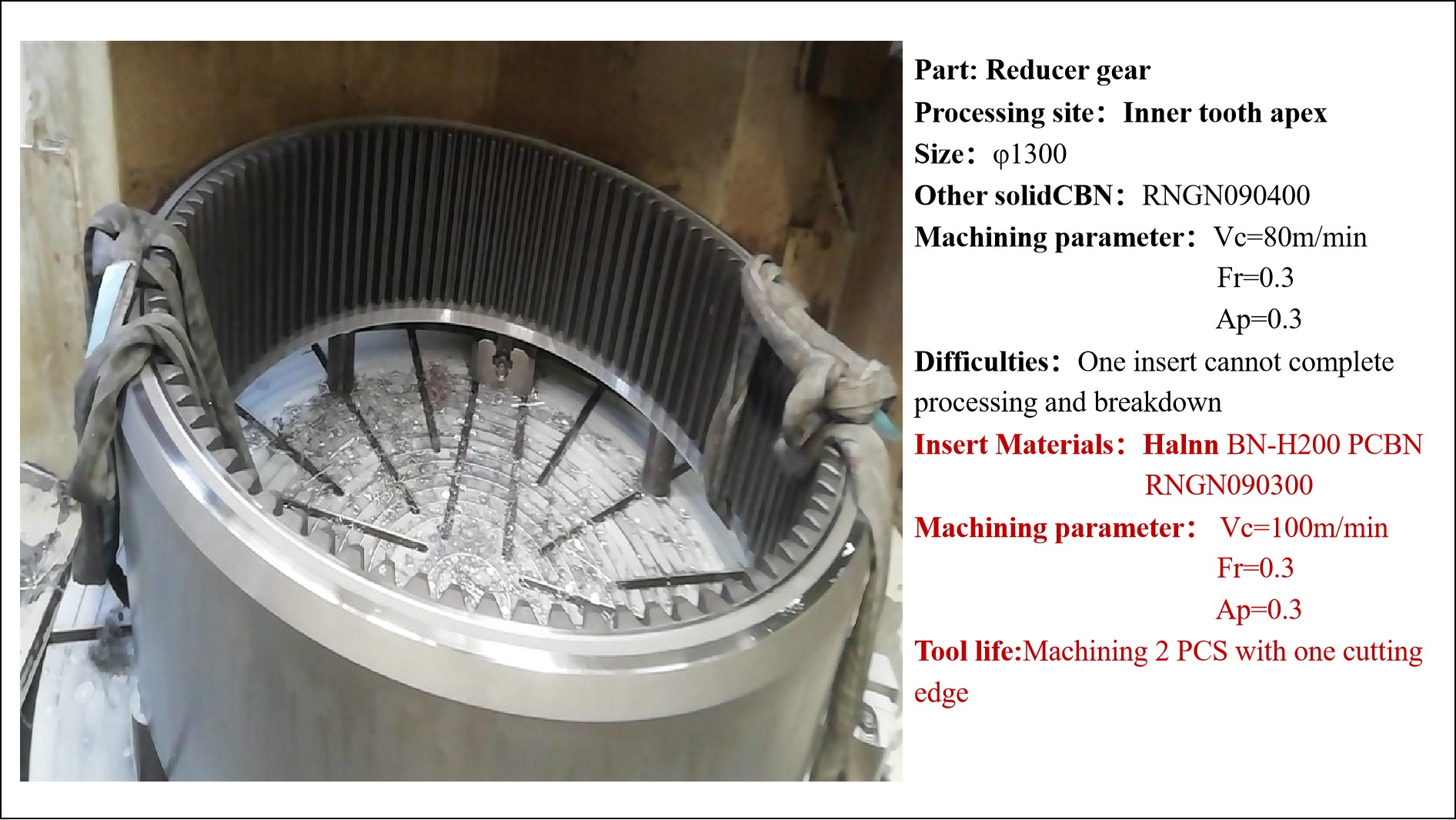

(1)This is the machining case on Wind turbine gear outer ring. The workpiece is the inner tooth tip of the wind turbine gear. With a diameter of 1300mm, the size of the workpiece is so large that the normal solid CBN RNGN090400 used by customers lead to the problem of tool broken, or even can no processed. Our suggestion is BN-H200 RNGN090300 PCBN inserts. After adjusting the cutting parameters, at least two products can be processed by 1 edge!

You can compare the workpiece before and after machining by Halnn inserts.Then there are three cases of gear process improvement of wind turbine reducer.

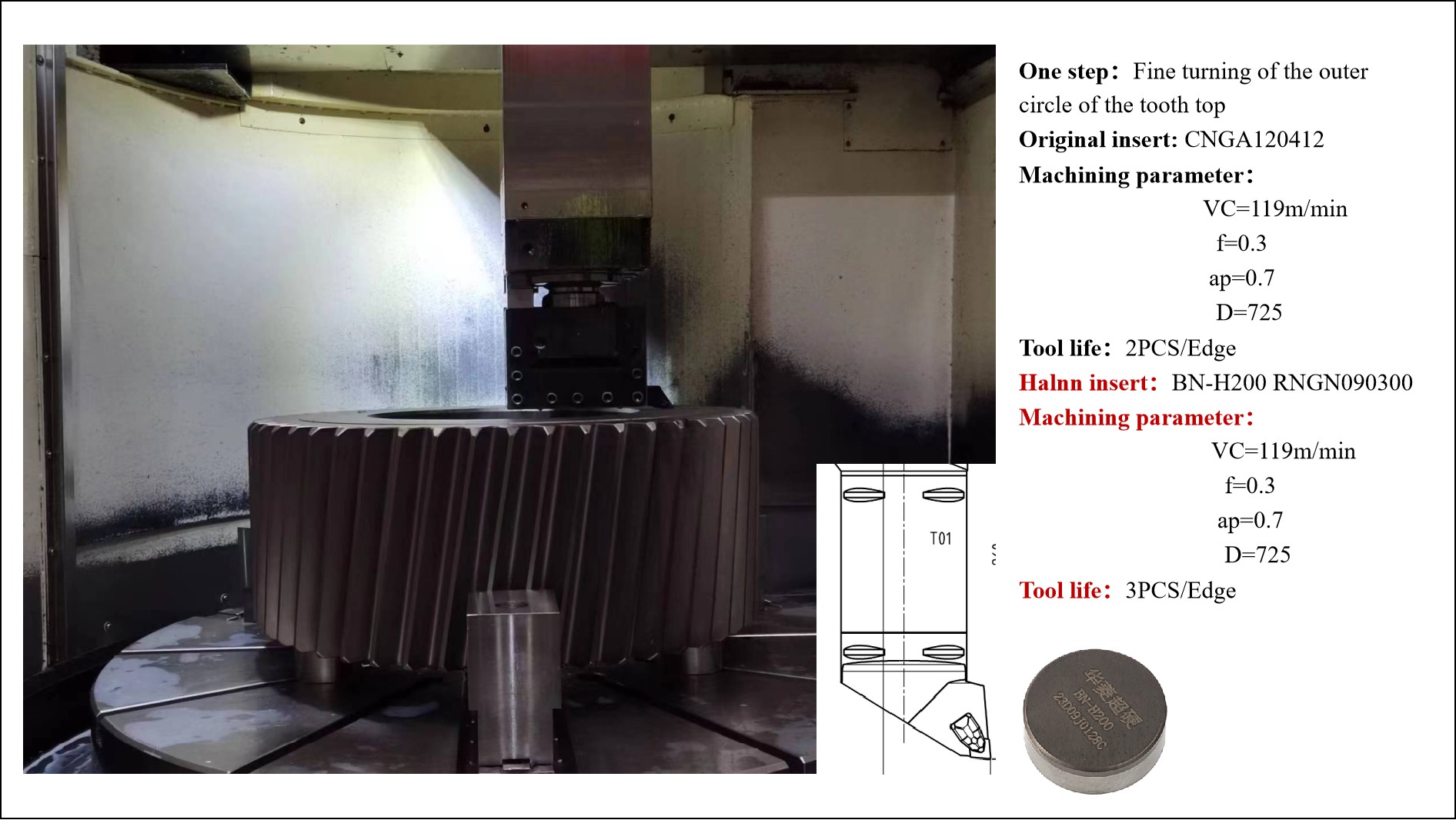

(2)This is the finish machining on the outer tooth tip circle. The original inserts used by customers are CNGA, and only 2 products can be processed with a single edge. Our suggestion is the CBN tools BN-H200 RNGN, under the same cutting parameters, the inserts can process three products with a single edge, and the efficiency can be improved by 50%.

(3)This is the rough machining of end surface and inner bore. with originally CNGA inserts, the surface quality is unqualified even process only two products. With our suggestion of BN-H200 RNGN060300 CBN tools, under preconditions of minimum lifespan of 2 PCS, more stable performance can be achieved.

(4)This is the finish machining of the end surface and inner bore. With the original DNGA150412, the surface quality cannot be guaranteed even it took 24 minutes to process. While with our solution of CBN tools BN-H200, the roughness can be controlled within 0.6. And the machining time of can be reduced to 8 minutes. The efficiency has been increased by three times.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.