PCD (polycrystalline diamond) tools are usually used in the manufacture, grinding and drilling of wind power blades. It gets great advantages in drilling on wind power blade because of its extremely hardness and wear resistance. Let me explain in details.

1.Material selection:

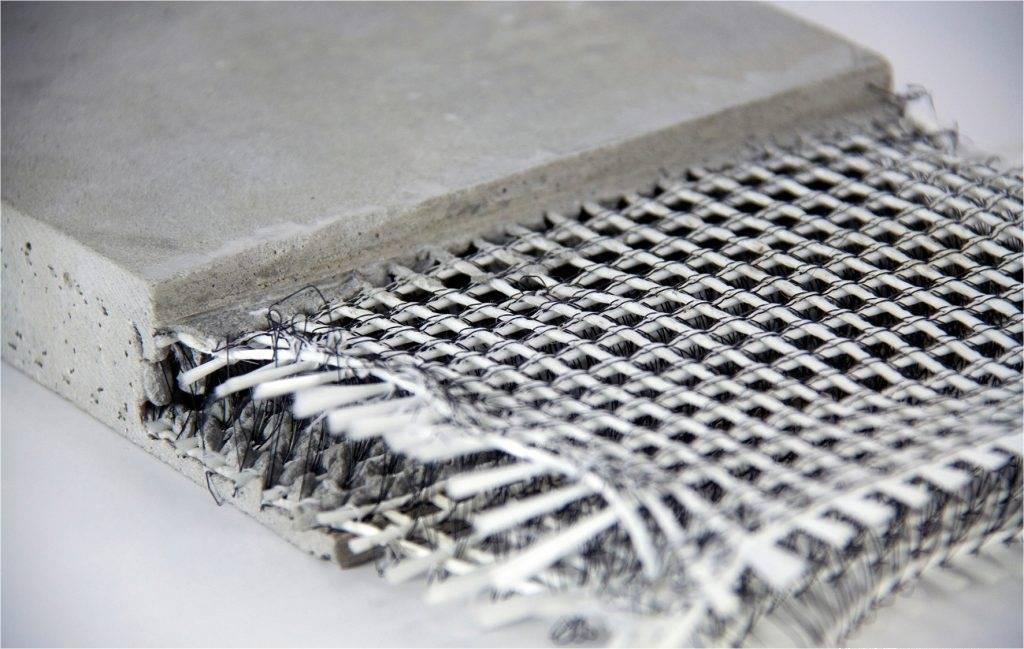

Wind power blades are usually made of composite materials, such as glass fiber, carbon fiber reinforced polymer or other lightweight materials. These materials are very tough and abrasive, and difficult to drill. PCD tools have excellent performance in drilling such materials because of its extremely hardness and high temperature resistance.

2.Tool selection:

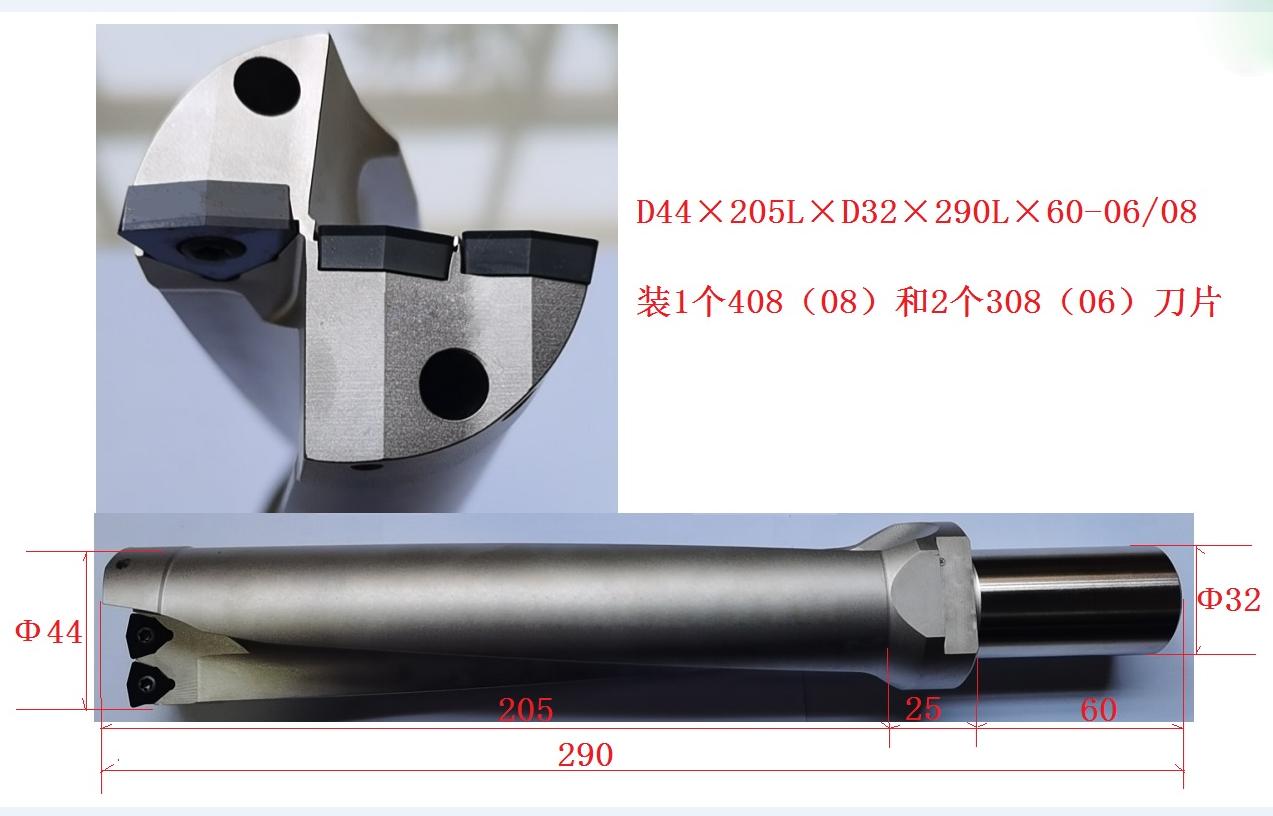

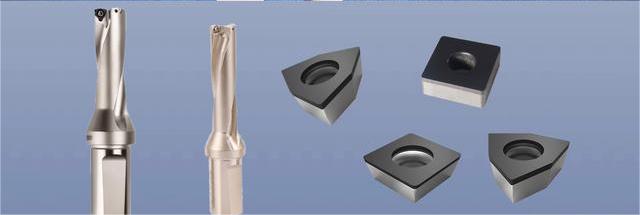

It is a good choice of PCD bit or inserts for drilling wind turbine blades. These tools are composed of carbonized objects and a layer of polycrystalline diamond combined with the cutting edge, and the diamond layer has excellent cutting performance and wear resistance.

3.Tool geometry:

PCD bits designed for drilling wind turbine blades are usually customized to meet specific requirements, this reduces the risk of glass fiber delamination or damage to blades.

4.machining parameters:

Cutting speed, feed rate, cutting depth and other machining parameters are carefully selected according to the specific materials of drilling. The goal is to balance productivity with tool`s life and hole quality. Compared with traditional tools, PCD tools can adopt higher cutting speed and feed rate. Then drilling speed and accuracy could be achieved.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.