The first part is cases for wind power gear sector:

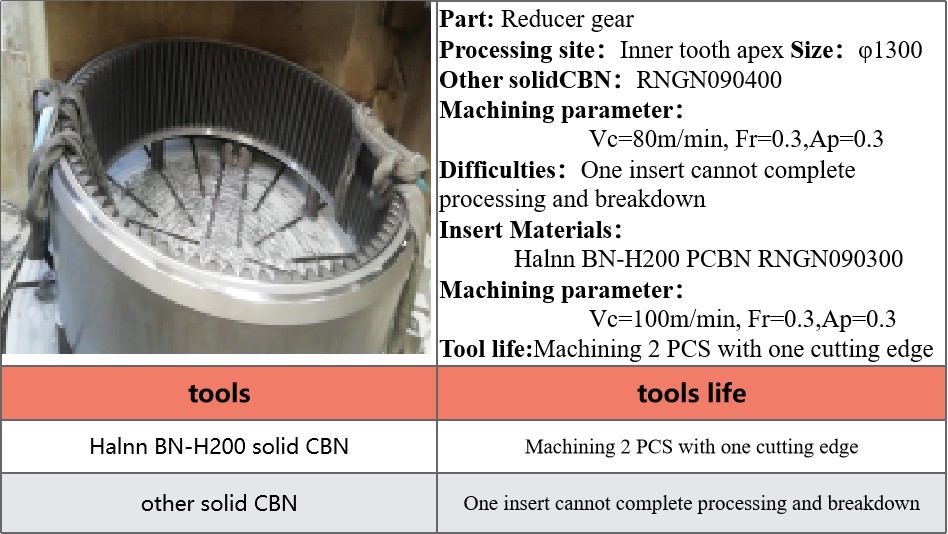

(1)Regarding the machining of out cycle of reducer gear, with our PCBN insert BN-H200, the cutting velocity has been increased from 80m/min to 100m/min. Compared with normal CBN inserts, the lifetime of our inserts could achieve 2 pieces/edge while the efficiency increased by 2 times.

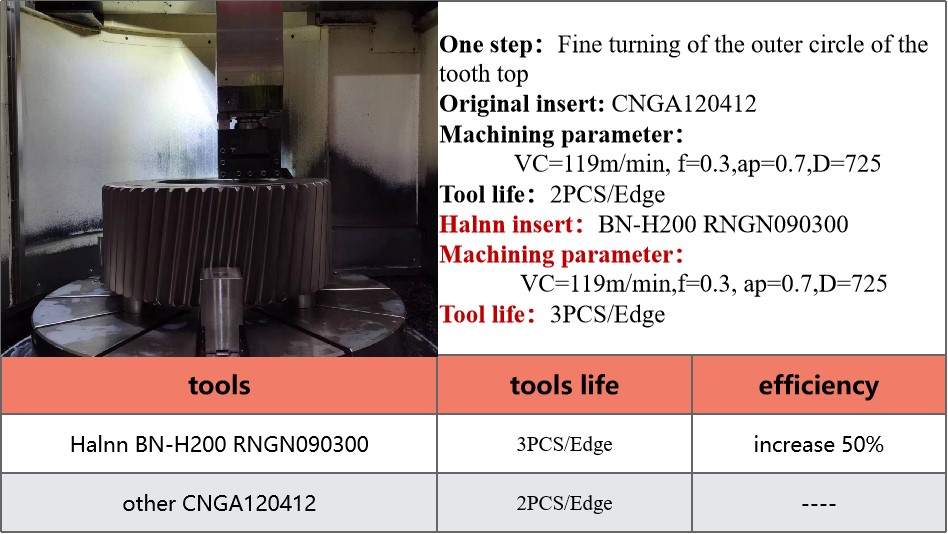

(2)Regarding the finish machining of the tooth tip cycle, with same cutting parameters, the efficiency of PCBN inserts BN-H200 increased by 50%, and the final failure form is normally wear.

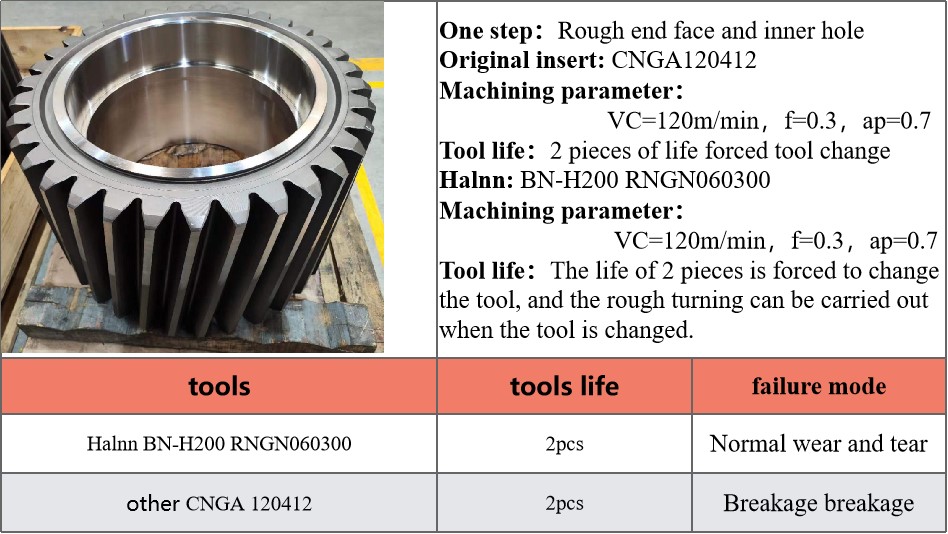

(3)Regarding the rough machining of end surface and inner bore, with our suggestion of PCBN inserts BH-H200 RNGN060300, the lifetime of at least 2 pieces can be achieved by more stable performance.

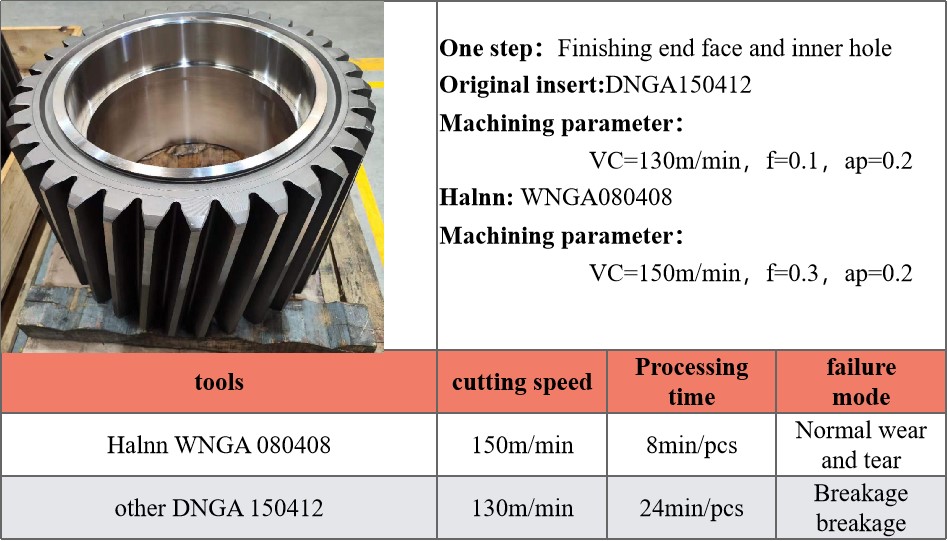

(4)Regarding finish turning of the end surface and inner bore, with Halnn`s PCBN inserts BN-H200 WNGA inserts, the Ra could be within 0.6 after machining the inner bore with the depth of 300. Meanwhile, the machining time reduced from 24 minutes to 8 minutes. The productivity increased by 3 times.

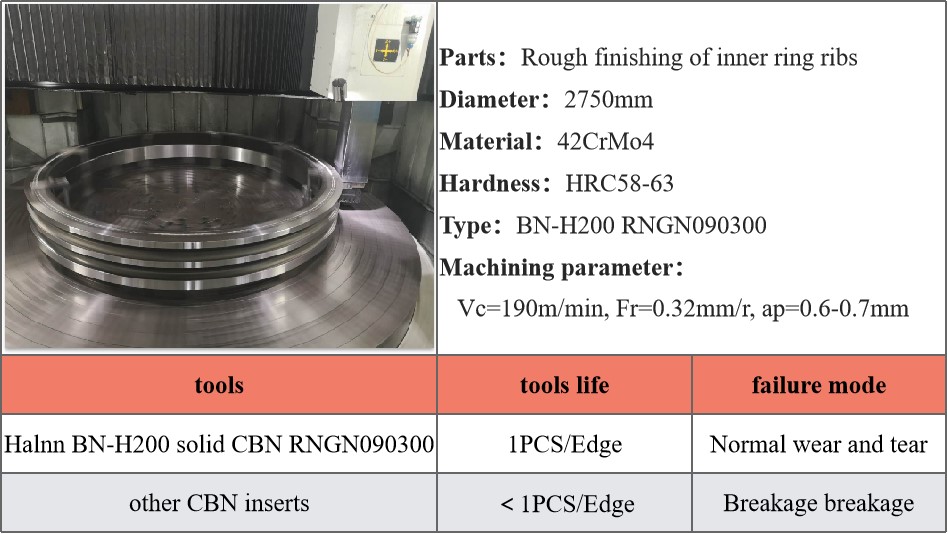

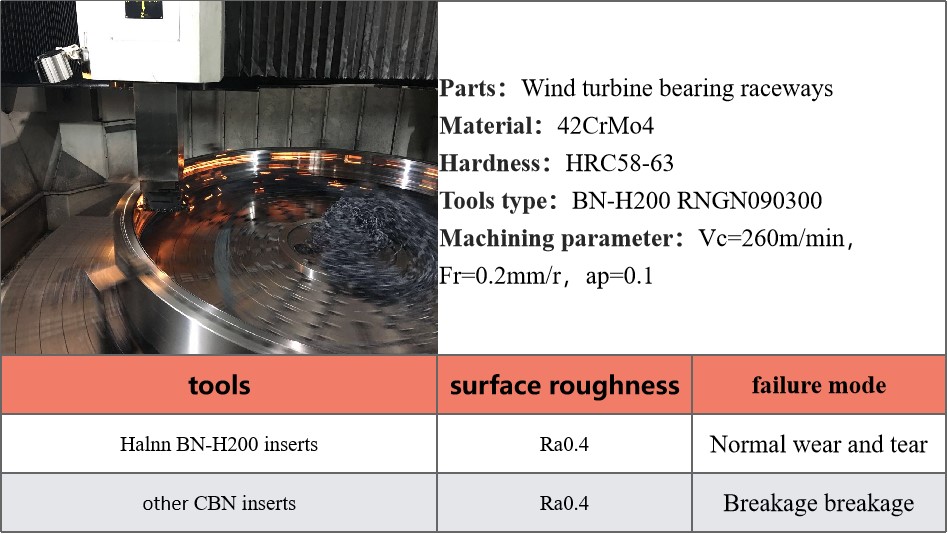

The second part is cases of wind power bearing field

(1)Regarding rough turning on inner ring channel, BN-H200 RNMN090300 PCBN inserts is suggested. With adjusted parameters and fine wear resistance, many previous problems could be solved, such as tolerance of pressure angle, roughness and scratches on the surface.

(2)Regarding the raceway machining of wind power bearing, with our solid CBN inserts RNMN090300, Ra 0.4 can be achieved and productivity can be improved significantly.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.