Cutting tools is a key role in the machining. As machining technology continues to improve, high precision and long life are increasingly sought after attributes by factory. In order to meet the ever-leaning and diversified needs, Halnn continues to innovate and enrich our product line, which provides strong support to help you achieve high efficiency and high precision machining.

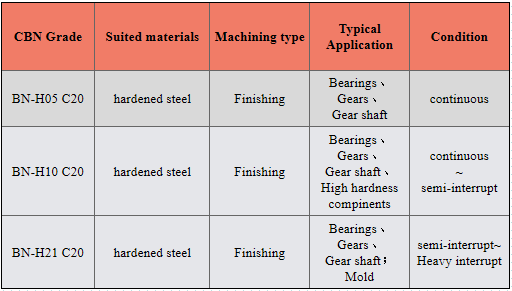

At present, Halnn BN-H05, BN-H10 and BN-H21 are the three common grades of coated PCBN inserts on the market. At the same time, Halnn has also upgraded the number of cutting edges, which doubles the number of cutting edges, and coupled with the exquisite coating technology, the life of the tool has been significantly improved.

BN-H05 C20 coating CBN inserts are an ultra-precision machining grade for continuous cutting with very high surface finish, BN-H10 C20 coating CBN inserts are a highly wear-resistant grade for continuous~Light-Interrupt process, and BN-H21 C20 coating CBN inserts is use for heavy-Interrupt finish machining conditions, with high resistance to chip and chipping. Gears, gear shafts, drive shafts, wind turbine bearings, wheel bearings, slewing bearings, ball screws, synchronizers, CV Joint, triple pins, cross shafts, etc., which are commonly found in hardened steel parts, can be easily machined with Halnn coated CBN inserts.

Here we will show two cases, coated and uncoated CBN inserts,

Both of them are the gears process, which can help you fast learn the advantages of coated CBN inserts.

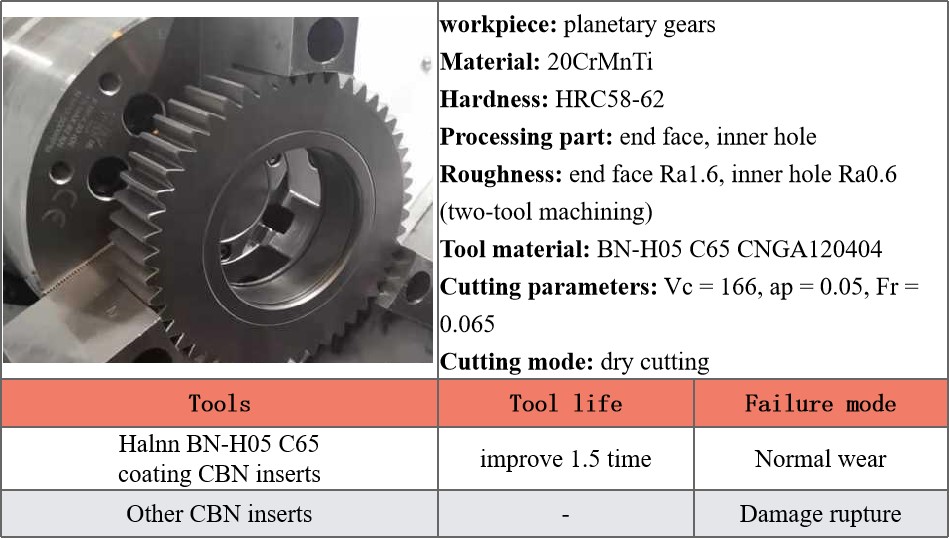

(1)Continuous Finishing gears

In this cases you can see our coated CBN inserts can improve 1.5 times work life and just for normal wearworkpiece: planetary gears

Material: 20CrMnTi

Hardness: HRC58-62

Processing part: end face, inner hole

Roughness: end face Ra1.6, inner hole Ra0.6 (two-tool machining)

Tool material: BN-H05 C65 CNGA120404

Cutting parameters: Vc = 166, ap = 0.05, Fr = 0.065

Cutting mode: dry cutting

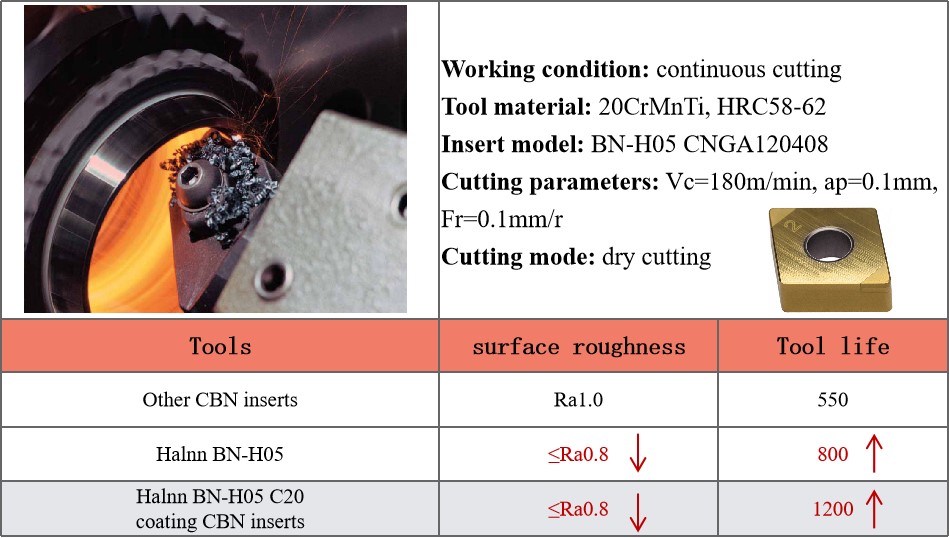

(2)Process parameters of coated CBN tools versus uncoated CBN inserts for finishing gears

In this cases you can see our coated CBN inserts can improve 1.5 times work life than uncoated inserts

Working condition: continuous cutting

Tool material: 20CrMnTi, HRC58-62

Insert model: BN-H05 C20 CNGA120408

Cutting parameters: Vc=180m/min, ap=0.1mm, Fr=0.1mm/r

Cutting mode: dry cutting

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.