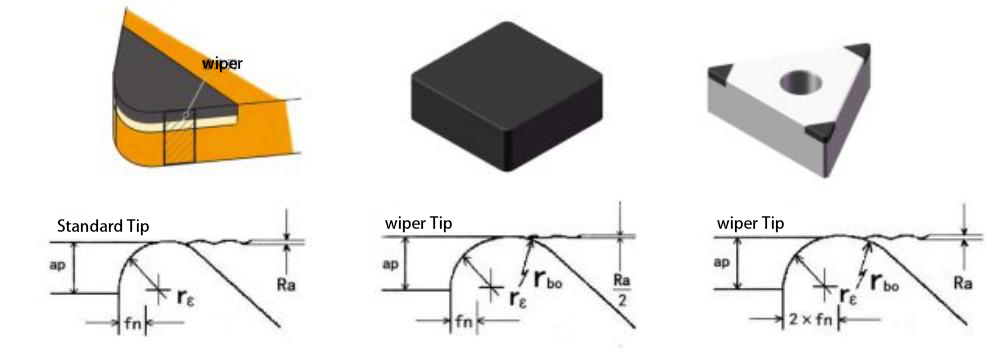

In addition to innovations in the field of chipbreaker and coating for CBN inserts, Halnn has carried out in-depth research and development in the area of CBN insert with wiper. Compared to conventional CBN inserts, CBN wiper inserts offer the following advantages:

Higher surface quality: Halnn CBN inserts with wiper achieve a higher surface quality of the workpiece at the same feed rate.

Improved machining efficiency: Halnn CBN inserts with wiper are able to utilize larger feeds while maintaining the same surface finish, which reduces machining time per part and significantly improves machining efficiency.

These advantages make CBN insert with wiper ideal for many high-precision, high-surface-demanding machining tasks.

Halnn used BN-S300 SCGN090412 CBN insert with wiper to replace traditional CBN insert. After machining 180 parts, the life of these tools has exceeded the life of conventional CBN tools by 20%. At the same time, the surface roughness of the workpieces remains within the reasonable range required by the customer. This is further proof of the excellent performance of Halnn's CBN insert with wiper, which has been recognized by our customers.

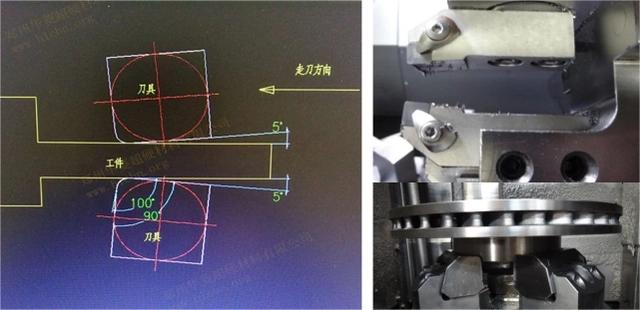

Wiper technology also belongs to "repeated cutting", which means that the machining forces is relatively high and the arc angle of the tool tip will also change. For this reason, the following two processing situations are not suitable for using wiper tools:

Inadequate Machine and Part Clamping Rigidity: If the clamping rigidity of the machine tool or the parts being processed is insufficient, the use of CBN wiper insert can easily cause vibration.

Profiling and Rounding: When a part is machined with profiling or rounding, CBN insert with wiper may not provide the desired finish due to the geometric angle of the tool tip.

Therefore, when choosing whether to use CBN insert with wiper, it is necessary to consider the rigidity of the machine tool and the part, the vibration situation, as well as the specific machining requirements. For the situation where CBN inserts with wiper are not suitable, other appropriate tools and machining methods should be selected to ensure the stability of the machining process and machining quality.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.