CBN tools, i.e. cubic boron nitride tools, are known as the "teeth of industry" because of their wide application in various machining. For brake discs (cast iron), gears (hardened steel), rolls (high-speed steel) and other common situations in the cutting process, in the face of high cutting forces, high cutting temperatures, machining hardening tendency, tool wear serious problems, you can consider the following different types of CBN tools to deal with:

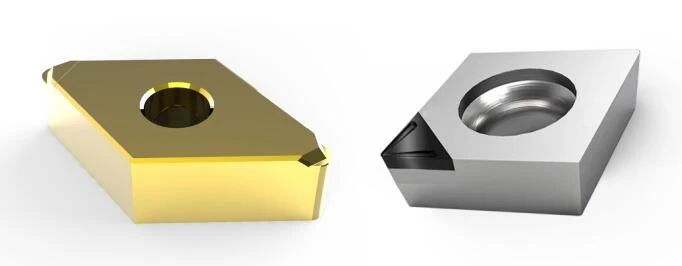

1、Heavy dutyTMSeries coating PCBN inserts

Characteristics: ① Use of ceramic bonding agent; ② Use of molybdenum as a synthetic mold under high temperature and high pressure; ③ Optimized edge passivation process; ④ Smooth coatings are perfectly combined with the base material;

Advantages: ①able to withstand heavy cutting for a long time and cutting force, high cutting temperature conditions; ②tool blank synthesized higher density, can obtain more excellent cutting performance; ③tool life, making the workpiece cost lower;④to improve machining accuracy.

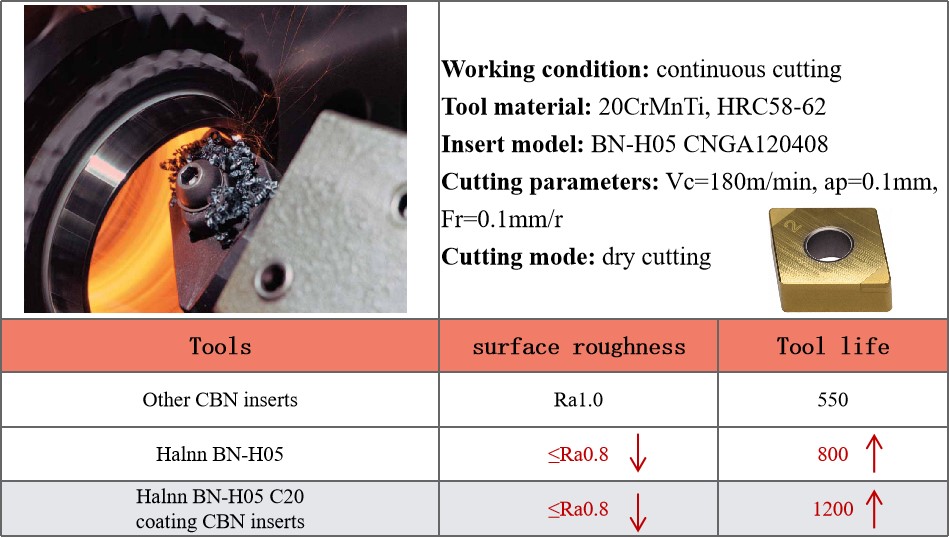

Case parameters for finishing gears with coated PCBN inserts:

2、LengthenTM Series PCBN inserts

Characteristics: ① cutting edge length 4mm; ② edge special treatment;

Advantages:① can realize cutting depth of 1.5mm heavy hard turning, semi-finishing and finishing clamping can be completed in one time; ② edge strength and stability is higher; ③ can strictly control the accuracy of the machined parts, machining efficiency is higher.

3、Breaking-GTM Series PCBN inserts with chipbreaker

Characteristics:① prepared by ultra-precision grinding machine. ② Can be combined with coating;

Advantages: ①With more stable performance, smooth surface ② can avoiding white layer, higher surface quality could be guaranteed.

4、WiperTM Series CBN insert

Characteristics: (1) rounded dressing edge; (2) straight dressing edge; (3) suitable for high rigidity machine tools and machining parts;

Advantages: (1) higher surface quality can be obtained under the same feed; (2) under the same surface roughness, large feed can be used to improve efficiency.

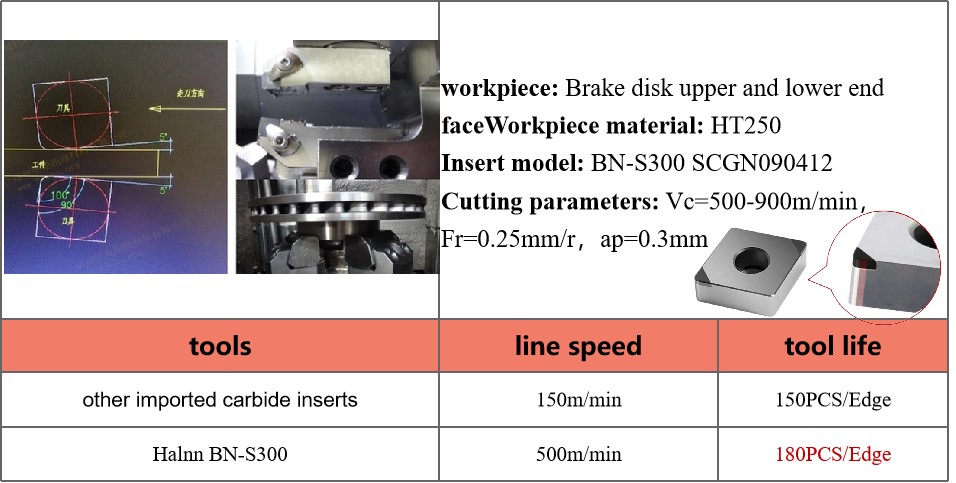

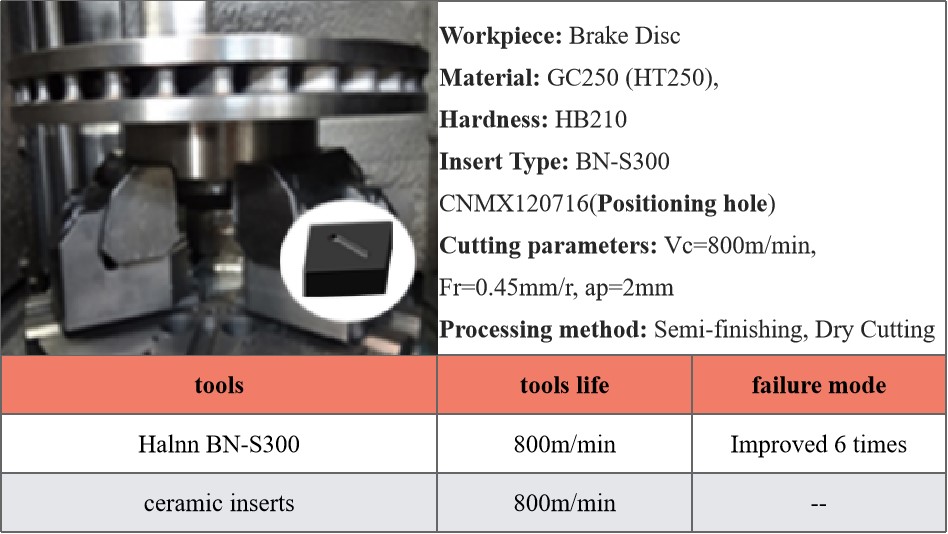

Case parameters for finishing brake discs with wiper PCBN inserts:

5、Fix-STM Series CBN Insert with Positioning Pit

Characteristics: ① for the solid CBN insert structure

Advantages: ① especially suitable for profiling and high-speed cutting; ② improve machining stability and tool loading accuracy; ③ reduce the vibration of the inserts during cutting, extend tool life.

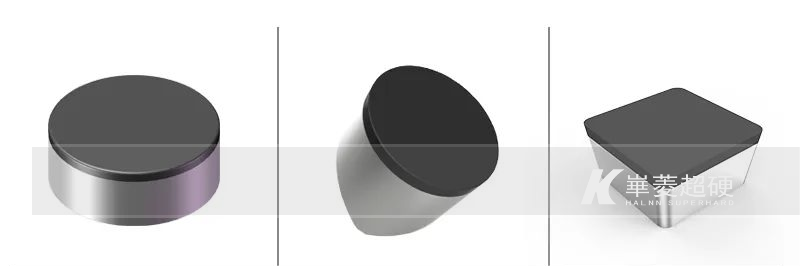

6、Full Face PCBN Insert Series

Characteristics: ①Multi-flute number.

Advantages:① excellent wear resistance, multi-edge number, reduce production costs; ② can withstand higher cutting speeds and feed speeds; ③ reduce the vibration of the inserts during cutting, extend tool life.

case Parameters of wind turbine gears finishing by PCBN full-face inserts:

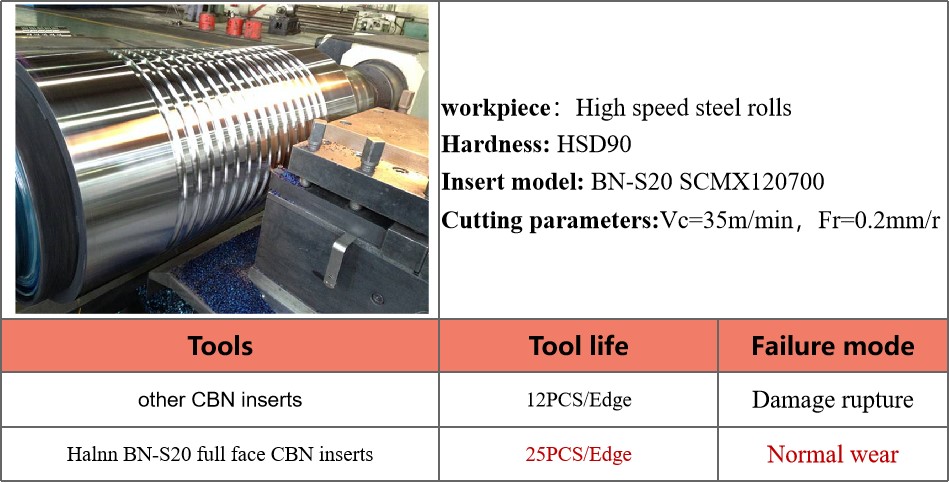

Case Parameters for turning HSS roll with PCBN full-face inserts:

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.