As a high load and high requirement cutting method, Heavy duty cutting characterized by cutting speeds above 38m/min, AP of 10mm or more, and feed rate of 0.5mm/r or more. Compared to normal machining, heavy duty cutting has a greater cutting depth, lower cutting speed, and slower feed rate.

In heavy duty cutting processes, vibration caused by poor workpiece balance, uneven distribution of machining allowance, and imbalance of certain components of the lathe during the cutting process requires a large amount of maneuvering and auxiliary time for the dynamic imbalance process of machining. Compared with ordinary turning tools, heavy cutting requires a larger cutting amount, and there are significant differences in working conditions and tool clamping methods. Therefore, tool design has its own significant characteristics in heavy duty cutting.

Io address the problems that arise during heavy cutting, more suitable materials, new design of chip breaker, and geometry solutions are developed by Halnn.

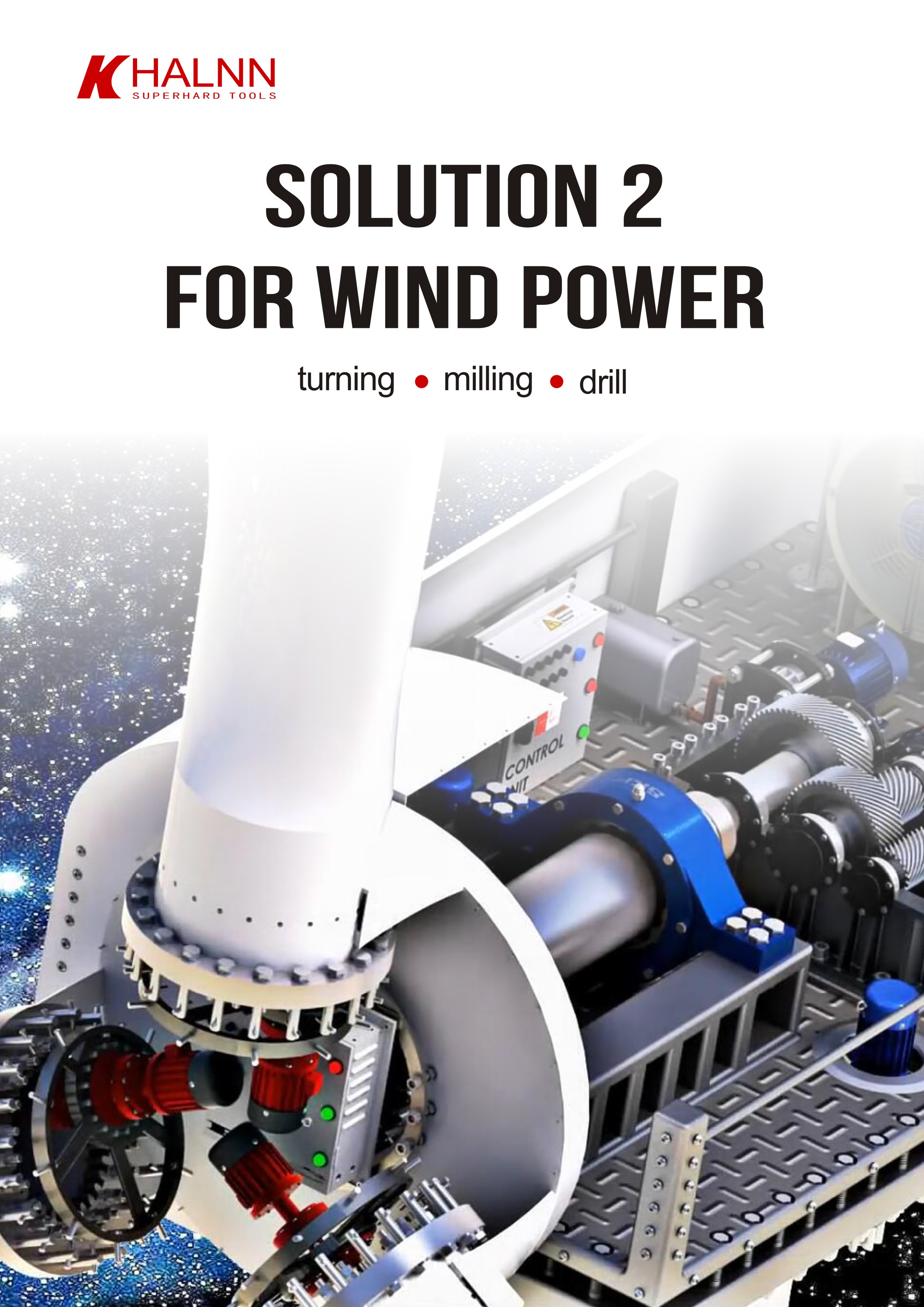

Rolling mill industry: Our Heavy-duty series full face PCBN(RCGX) tools have a fine performance on machining rolls. The ceramic binders are adopted instead of metal binders such as aluminum and cobalt, allowing the tools get better performance under classic heavy-duty working condition such as long-term, high cutting force, and high cutting temperature.

The Heavy-duty series of solid CBN and ceramic inserts are designed specifically for roller machining and can meet various specific requirements for heavy-duty cutting. Whether you need to process rolls materials such as HSS, carbide, or other materials, Halnn can provide a complete set of solutions according to your requirements.

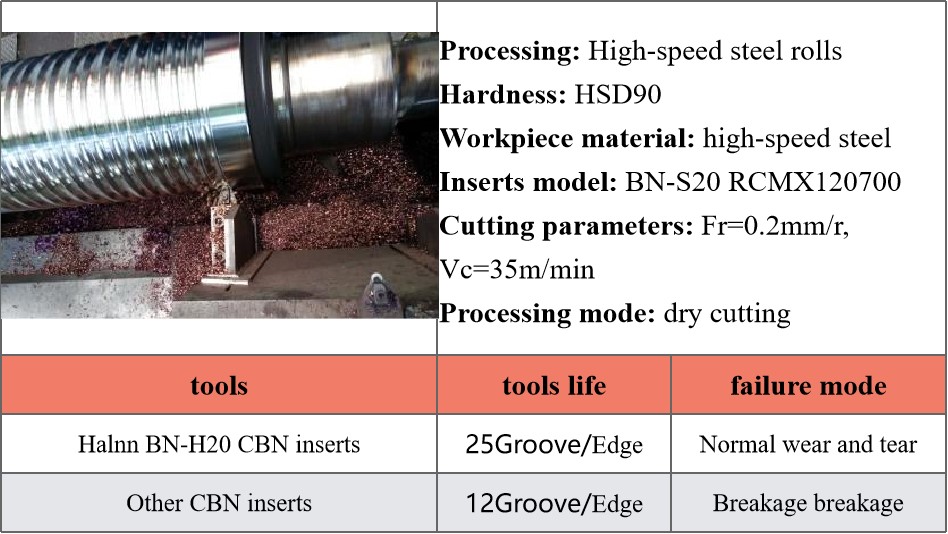

Wind power industry: Our BN-H200 PCBN(RNGN) inserts in Heavy duty TM series, are stable and durable during high load processing. Meanwhile, with the optimized edge passivation process, our tools could compete with world famous brands in global market. In the global wind power field, Halnn take over more than 50% market shares.

Due to the high hardness and good wear resistance, Halnn's CBN inserts in heavy duty series have become an ideal selection for supporting suppliers in fields such as mill rolls, wind power bearings, mining machinery, and heavy machinery.

Here are some applications of CBN inserts of heavy duty series:

HSS roll grooving: The hardness of the roller has reached HSD90. The customer adopted the Halnn Heavy Duty series BN-S20 RCGX full face PCBN insert, which have a tool life that is twice of a normal CBN insert.

Finish machining of wind turbine gear outer circle: Heavy Duty series BN-H200 full face PCBN insert was selected. With same parameters, Halnn`s inserts could complete 3 pieces while the productivity could be increased by 50%.

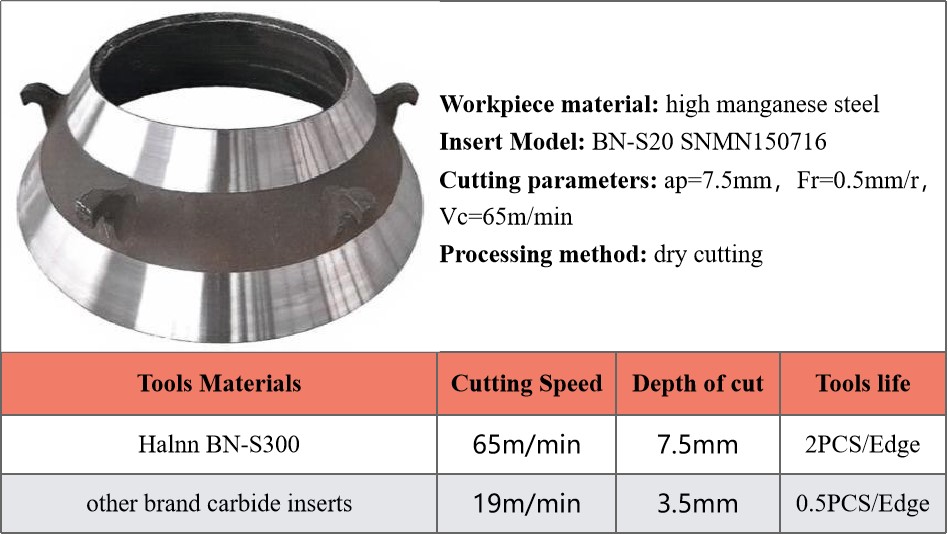

Turning of rolling mortar wall cylinders: With the BN-S20 material of the Halnn Heavy Duty series solid CBN insert, the production efficiency is doubled; Compared to traditional cutting tools, the lifespan of the tool is increased by several times.

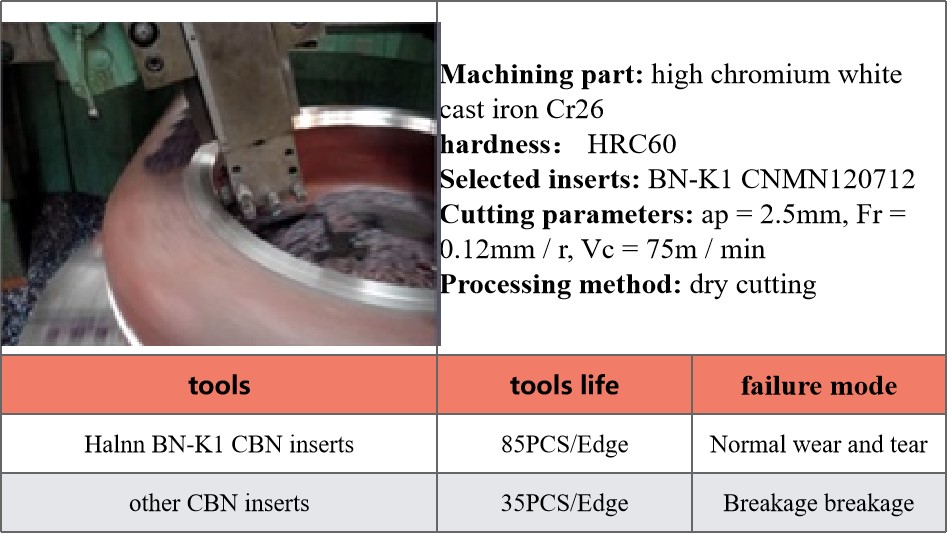

Mining machinery slurry pump pump casing cutting: Material hardness is HRC60. With Halnn Heavy Duty series solid CBN insert BN-K1, stable cutting performance and high cost-effectiveness could be achieved.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.