Definition: Piston groove tools are specialized machining instruments designed to create precise grooves in piston components. These grooves are crucial for housing piston rings, which are essential for maintaining the seal and proper functioning of internal combustion engines.

Importance: The role of piston groove tools in manufacturing cannot be overstated. They ensure that piston grooves are machined with high precision and efficiency, directly affecting the engine's performance, fuel efficiency, and longevity. Utilizing high-quality piston groove tools, such as those offered by Halnn Group, can significantly enhance the overall quality and reliability of piston components.

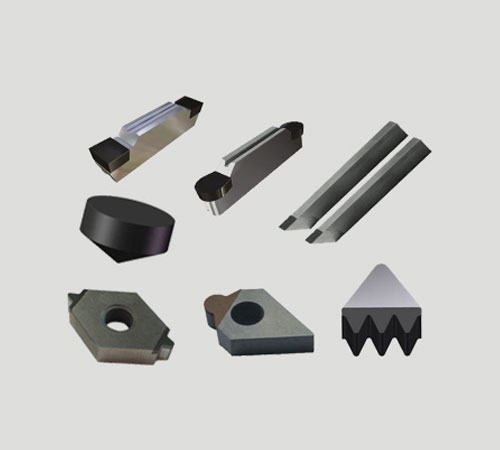

There are various types of groove tools used in piston manufacturing, each serving specific purposes in the machining process.

Turning Tools: Used for cutting the external grooves on pistons.

Milling Cutters: Employed for machining grooves with precise dimensions and surface finishes.

Broaches: Ideal for creating grooves with intricate profiles and tight tolerances.

Honing Tools: Used for finishing grooves to achieve the desired surface texture and dimensional accuracy.

Each tool type has a distinct function:

Turning Tools: Efficiently cut and shape the piston’s outer grooves.

Milling Cutters: Provide high precision and smooth finishes for grooves.

Broaches: Perfect for complex groove shapes and maintaining strict tolerances.

Honing Tools: Ensure high-quality surface finishes and precise dimensions.

Material Compatibility: Selecting tools compatible with the materials used in piston manufacturing is vital. Common materials include cast iron, aluminum, and steel. Piston groove tools must be robust enough to handle the specific properties of these materials without compromising performance or tool life.

Precision and Accuracy: High precision and accuracy are paramount in piston machining to ensure that grooves meet exact specifications. Tools must maintain tight tolerances and produce high-quality surface finishes to ensure optimal performance of piston rings.

Durability and Tool Life: Durable tools with long tool life are essential for cost-effective manufacturing. High-quality materials and advanced coatings can significantly extend tool life, reducing the frequency of replacements and downtime.

Groove Dimensions: The dimensions of the grooves to be machined are a primary consideration. Tools must be selected based on the specific width, depth, and profile of the grooves required for the piston design.

Tool Material and Coating: Choosing the right tool material and coating is crucial for performance and longevity. Materials such as carbide, CBN (Cubic Boron Nitride), and PCD (Polycrystalline Diamond) are commonly used for their wear resistance and thermal stability. Advanced coatings can further enhance these properties.

Cost-effectiveness: Evaluating the overall cost-effectiveness involves considering the initial investment, tool life, and productivity. High-quality tools might have a higher upfront cost but offer significant savings through extended life and improved machining efficiency.

Tool Setup and Alignment: Proper setup and alignment of groove tools are critical to achieving optimal performance. Ensuring that tools are correctly positioned and securely fastened helps maintain precision and prevents tool wear.

Optimizing Cutting Parameters: Cutting speed, feed rate, and depth of cut should be optimized to maximize efficiency and tool life. Manufacturers like Halnn Group provide guidelines for these parameters based on specific tool types and materials.

Coolant and Lubrication: Using appropriate coolants and lubricants can significantly reduce tool wear and prevent overheating. This not only prolongs tool life but also improves the quality of the machined grooves.

Routine Maintenance: Regular maintenance procedures, including cleaning, inspection, and lubrication, are essential for keeping tools in optimal condition. This prevents buildup of debris and ensures smooth operation.

Tool Sharpening and Reconditioning: Techniques for sharpening or reconditioning worn tools can extend their service life. Ensuring that cutting edges are sharp and free of defects maintains machining quality.

Storage and Handling: Proper storage and handling are crucial to prevent damage to groove tools. Tools should be stored in a dry, clean environment and handled with care to avoid chipping or other damage.

Advanced Materials and Coatings: Recent advancements in tool materials and coatings have significantly enhanced tool performance and durability. Innovations such as nano-coatings and advanced carbide grades offer superior wear resistance and thermal stability.

Technological Developments: Cutting-edge technologies, including CNC (Computer Numerical Control) machining, automation, and tool monitoring systems, have revolutionized piston manufacturing. These technologies enable higher precision, faster production times, and reduced manual intervention.

Future Trends: The future of piston groove tool technology is likely to see further advancements in materials, coatings, and machining techniques. Increased automation and smart manufacturing solutions will continue to improve efficiency and precision in piston manufacturing.

Piston groove tools are essential for manufacturing high-quality pistons with precision and efficiency. Selecting the right tools, optimizing machining parameters, and maintaining tools properly are critical for achieving optimal performance.

For more information on high-quality piston groove tools, visit our website: Halnn-group, Halnn-pcd, Halnn-cbn, or contact our experts to discuss your specific machining needs. Investing in advanced groove tools can significantly enhance your manufacturing processes and product quality.

A1: Piston groove tools are used to machine precise grooves in piston components, which are essential for housing piston rings and ensuring proper engine function.

A2: Piston groove tools are typically compatible with materials like cast iron, aluminum, and steel. Selecting the right tool material and coating is crucial for performance and longevity.

A3: Consider factors such as groove dimensions, tool material and coating, and cost-effectiveness. Ensuring the tool is compatible with the material being machined and optimizing cutting parameters are also important.

A4: Advanced piston groove tools offer enhanced precision, durability, and efficiency. They help achieve better surface finishes, reduce machining time, and extend tool life, leading to cost savings and improved product quality.

A5: Routine maintenance includes cleaning, inspection, and lubrication. Sharpening or reconditioning worn tools and proper storage and handling are also crucial to extend their service life.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.