With the rapid development of the automobile industry, the demand for automobile parts in the market is also increasing. In order to meet the growing demand, the processing requirements of brake discs are also increasing.

The material of the brake disc adopts my country's gray cast iron 250 standard, referred to as HT250, which is equivalent to the American G3000 standard.

Brake disc manufacturers mostly use carbide inserts to process brake discs. However, with the development of material technology and the improvement of processing efficiency requirements, carbide inserts are no longer suitable for processing brake discs due to problems such as low hardness, poor wear resistance, and low cutting speed. Meet the demand for mass processing of brake discs.

Currently, manufacturers that produce brake discs in large quantities mostly use Halnn CBN cubic boron nitride cutting inserts. Because its CBN tool has high hardness and good wear resistance, it can meet the requirements of high-speed cutting of brake discs, improves brake disc processing efficiency, and thereby reduces brake disc processing costs. Among them, Halnn's BN-S300 and BNK30 occupy a large market position in the field of brake discs. The blade has excellent wear resistance and high temperature red hardness. And it can replace imported foreign inserts, reducing costs.

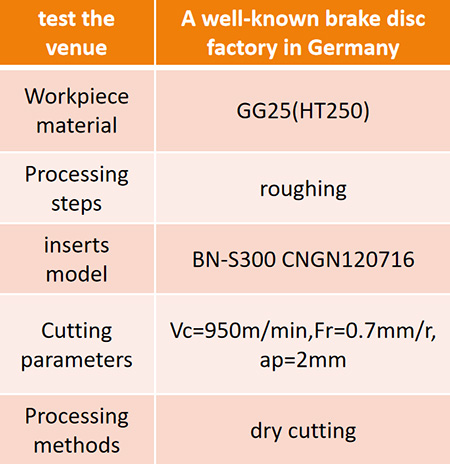

In the process of brake disc production and processing, taking a brake disc manufacturer as an example, the use of CBN cubic boron nitride blades produced by Zhengzhou Halnn effectively solved the difficult problems in brake disc processing and improved the brake disc processing efficiency. Smaller dimensional fluctuations and longer service life.

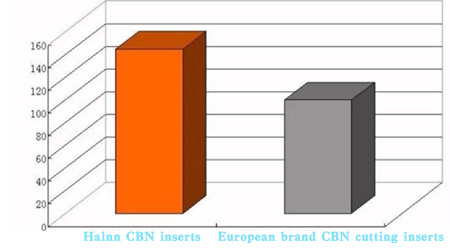

Under the same cutting parameters, the tool life of Valin BN-S300 is 1.45 times that of a European CBN insert.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.