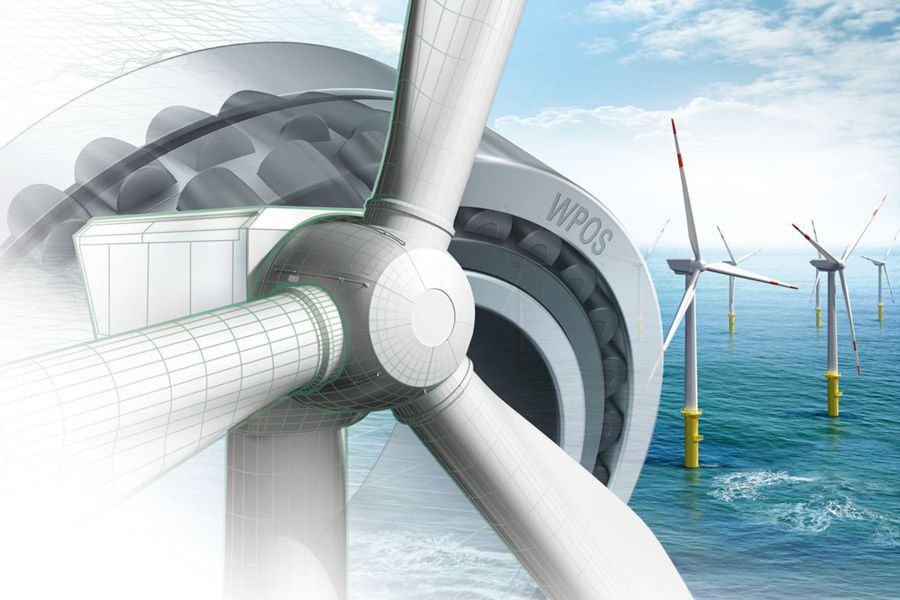

In the renewable energy sector, wind turbines play a crucial role in sustainable power generation. A key component ensuring the efficiency and reliability of these turbines is the gear system. The precision machining of wind turbine gears is paramount to their performance and longevity. This article delves into the intricacies of wind turbine gear machining tools, providing valuable insights for industry professionals and showcasing the expertise of Halnn Group in this domain.

Wind turbine gears, essential for converting kinetic energy from wind into electrical power, come in various types, including planetary gears and helical gears. These gears are typically made from high-strength steel or composite materials, designed to withstand extreme operational conditions. Machining these gears presents several challenges, such as maintaining tight tolerances and achieving superior surface finishes to ensure efficient power transmission and durability.

Cutting tools are fundamental in shaping wind turbine gears. Types of cutting tools include end mills, gear hobs, and broaches. The material composition of these tools, such as carbide, CBN (Cubic Boron Nitride), and PCD (Polycrystalline Diamond), significantly impacts their performance. CBN and PCD tools, offered by Halnn Group, provide exceptional hardness and wear resistance, making them ideal for high-precision applications.

Precision grinding is crucial for finishing gears to exact specifications. Grinding tools like grinding wheels and CBN grinding discs are employed to achieve the desired surface finish and dimensional accuracy. Halnn Group's CBN grinding solutions ensure high efficiency and consistency in gear production.

Ensuring the accuracy of machined gears requires advanced measuring and inspection tools. Coordinate Measuring Machines (CMMs) and laser scanners are used to verify gear dimensions and tolerances. These tools are essential for maintaining the high quality and reliability of wind turbine gears.

The development of superhard materials like CBN and PCD has revolutionized gear machining. These materials offer superior wear resistance and thermal stability, enabling manufacturers to achieve higher precision and longer tool life. Halnn Group's cutting-edge tools leverage these advanced materials to deliver exceptional performance.

Recent advancements in grinding technology have significantly improved gear machining processes. Techniques such as high-speed grinding and adaptive control systems enhance the precision and efficiency of gear production. Halnn Group's innovative grinding solutions incorporate these advancements, ensuring optimal results.

The integration of CNC machines and robotics in gear machining processes has streamlined production and increased consistency. Automated systems reduce human error and enhance productivity. Halnn Group utilizes state-of-the-art CNC technology to deliver high-precision machining solutions.

Selecting the right tools is critical for machining wind turbine gears. Factors to consider include material hardness, cutting speed, and feed rate. Regular maintenance of tools, such as proper cleaning and re-sharpening, extends their lifespan and maintains machining quality.

Optimizing machining parameters, including cutting speeds, feeds, and depths, is essential for efficient and effective gear production. Proper parameter settings minimize tool wear and improve surface finishes, enhancing overall gear performance.

Implementing rigorous quality control measures ensures the production of high-quality gears. Key checkpoints include dimensional inspection, surface roughness measurement, and defect detection. Halnn Group adheres to stringent quality standards to deliver reliable machining solutions.

The future of gear machining is poised to benefit from emerging technologies such as additive manufacturing and artificial intelligence. These advancements hold the potential to further enhance machining precision and efficiency.

Sustainable machining practices, including the use of eco-friendly cutting fluids and energy-efficient machinery, are gaining traction. Halnn Group is committed to promoting sustainability in gear machining by adopting green practices and reducing waste.

Machining wind turbine gears requires specialized tools and expertise to meet the stringent demands of the industry. Halnn Group, with its advanced CBN and PCD tools, offers reliable and efficient solutions for high-precision gear machining. For more information on our products and services, visit our website: Halnnpcd, Halnncbn, Halnn group or contact us directly.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.