Crankshaft cutting tools are essential components in the manufacturing of engine parts, playing a critical role in ensuring precision and efficiency. At Halnn, we specialize in providing high-quality crankshaft cutting tools designed to meet the rigorous demands of modern manufacturing. This article delves into the intricacies of crankshaft cutting tools, offering valuable insights and highlighting why Halnn is the go-to choice for industry professionals.

Crankshaft cutting tools are specialized instruments used to machine crankshafts, a crucial component in internal combustion engines. These tools are designed to cut, shape, and finish crankshafts with high precision, ensuring they meet exact specifications.

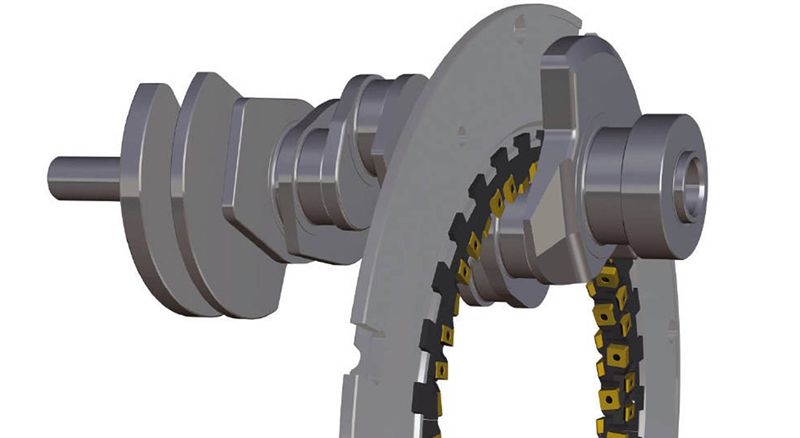

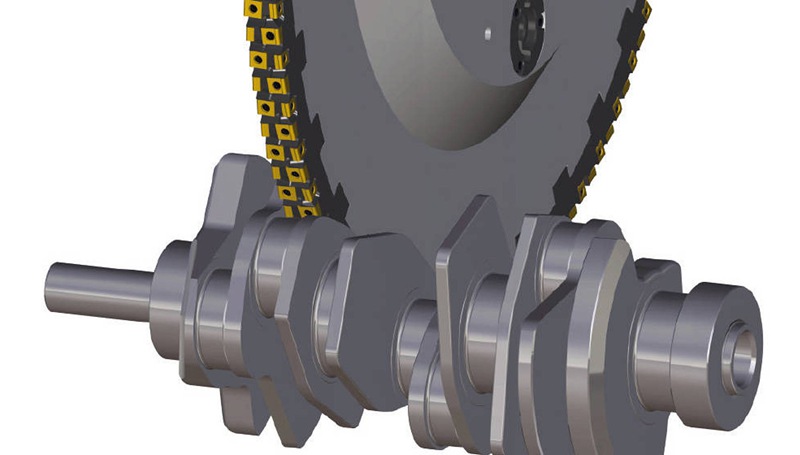

External Crankshaft Milling Cutters: Used for machining the outer surfaces of crankshafts. They are essential for ensuring the crankshaft's external features are accurately shaped and finished.

Internal Crankshaft Milling Cutters: Designed for internal machining tasks, such as cutting internal grooves and slots within the crankshaft.

The performance and reliability of an engine heavily depend on the precision of its crankshaft. Crankshaft cutting tools ensure that every crankshaft meets the required standards, contributing to the engine's overall efficiency and durability.

Machining crankshafts is complex due to their intricate shapes and the need for high precision. The process requires tools that can handle the tough materials and demanding conditions involved in crankshaft manufacturing.

External crankshaft milling cutters are crucial for shaping and finishing the outer surfaces of crankshafts. These cutters must be robust and precise to handle the external contours and ensure a smooth finish.

Internal crankshaft milling cutters are used for machining the internal features of crankshafts, such as grooves and slots. These tools are designed to reach internal areas while maintaining high precision and efficiency.

High-quality crankshaft cutting tools are typically made from durable materials such as carbide and high-speed steel, which offer excellent wear resistance and longevity.

Coatings like Titanium Nitride (TiN), Titanium Carbo-Nitride (TiCN), and Aluminum Titanium Nitride (AlTiN) enhance the performance of cutting tools by reducing friction and increasing hardness.

The design and geometry of crankshaft cutting tools are critical for achieving optimal cutting performance. Advanced designs ensure efficient material removal and precise finishing.

Halnn crankshaft cutting tools are renowned for their superior quality and precision. Our tools are engineered to deliver exceptional performance, ensuring every cut is accurate and consistent.

At Halnn, we utilize cutting-edge technology and innovative processes to manufacture our crankshaft cutting tools. This commitment to innovation ensures our tools meet the highest industry standards.

Our clients consistently praise the reliability and performance of Halnn crankshaft cutting tools. Case studies highlight significant improvements in production efficiency and product quality after implementing our tools.

When selecting crankshaft cutting tools, consider the material of the crankshaft, the required surface finish, and the production volume. These factors will influence the type and specifications of the tools needed.

Halnn offers custom tool solutions tailored to specific applications. Our team works closely with clients to develop tools that meet their unique requirements, ensuring optimal performance and efficiency.

Proper setup and maintenance of crankshaft cutting tools are crucial for achieving the best results. Regular maintenance and correct setup help extend tool life and maintain cutting performance.

Optimizing cutting parameters, such as cutting speed and feed rate, is essential for maximizing efficiency and minimizing tool wear. Proper parameter optimization leads to improved productivity and product quality.

Crankshaft milling cutters are tools specifically designed for machining the surfaces of crankshafts, ensuring they meet precise specifications.

External crankshaft milling cutters machine the outer surfaces, while internal crankshaft milling cutters are used for internal features like grooves and slots.

Crankshaft cutting tools are specialized tools designed for machining crankshafts, which are critical components in internal combustion engines. These tools are used to shape, cut, and finish crankshafts to meet precise specifications.

There are several types of crankshaft cutting tools, including:

External Crankshaft Milling Cutters: Used for machining the external surfaces of the crankshaft.

Internal Crankshaft Milling Cutters: Designed for internal machining tasks, such as cutting grooves and recesses inside the crankshaft.

Precision is crucial in crankshaft cutting because the crankshaft's accuracy directly affects engine performance and reliability. Precise cutting ensures that the crankshaft meets stringent dimensional and tolerance requirements.

Crankshaft cutting tools are typically made from durable materials such as carbide. These materials offer excellent wear resistance and long tool life, essential for handling the tough materials used in crankshaft manufacturing.

External crankshaft milling cutters are used to machine the outer surfaces of the crankshaft, ensuring proper shaping and finishing. Internal crankshaft milling cutters, on the other hand, are used to machine internal features like grooves and recesses within the crankshaft.

High-quality crankshaft cutting tools provide several benefits, including:

Improved precision and surface finish

Increased production efficiency

Reduced tool wear and longer tool life

Consistent machining performance

The design and geometry of crankshaft cutting tools are critical for optimal cutting performance. Advanced tool designs ensure efficient material removal, reduced cutting forces, and improved surface finish.

Proper maintenance is key to maximizing the performance and lifespan of crankshaft cutting tools. Best practices include:

Regular inspection for wear and damage

Proper cleaning and storage

Using appropriate cutting parameters

Ensuring correct tool setup and alignment

Yes, many manufacturers, including Halnn, offer custom crankshaft cutting tools tailored to specific machining needs. Custom tools are designed to meet unique requirements, ensuring optimal performance and efficiency.

Cutting parameters such as cutting speed, feed rate, and depth of cut significantly impact the machining process. Optimizing these parameters can enhance cutting efficiency, reduce tool wear, and improve the overall quality of the crankshaft.

Recent advancements in crankshaft cutting tool technology include the development of new tool materials, advanced coatings, and improved tool geometries. These innovations enhance tool performance, durability, and machining accuracy.

Halnn is a reputable provider of high-quality crankshaft cutting tools. We offer a wide range of tools designed for various crankshaft machining applications, ensuring precision, efficiency, and reliability.

Halnn offers comprehensive technical support and services to assist clients with their crankshaft cutting tool needs. Our expert team is available to provide guidance and answer any technical questions.

Crankshaft cutting tools are vital for the precise machining of crankshafts, ensuring high performance and reliability of engines. Halnn's superior quality and innovative technology make us the leading choice for crankshaft cutting tools. By choosing Halnn, you are investing in tools that deliver exceptional performance, efficiency, and value.

For more information on our products and services, visit Halnn's official website or contact our customer support team. Explore our range of crankshaft cutting tools and discover how we can help you enhance your manufacturing processes.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.