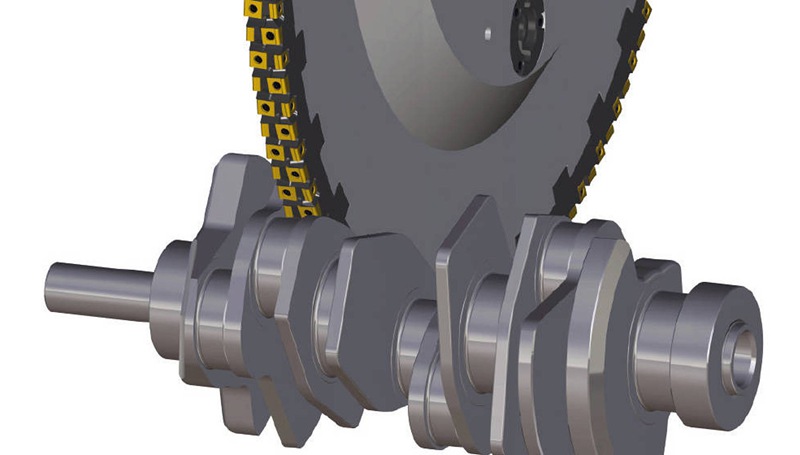

In the demanding world of automotive and industrial manufacturing, precision and efficiency are paramount. Crankshaft machining, a critical process in engine production, requires specialized tools to meet these high standards. Halnn, a leader in cutting tool technology, offers advanced indexable crankshaft cutters designed to enhance performance and reliability. This article delves into the benefits, features, and applications of Halnn's indexable crankshaft cutters.

An indexable crankshaft cutter is a specialized tool used for machining crankshafts. Unlike traditional fixed-blade cutters, these tools feature replaceable inserts, known as indexable inserts. This design allows for continuous use without the need for re-sharpening, significantly enhancing productivity and reducing downtime.

Improved Productivity: The replaceable inserts mean that tools can be quickly and easily refreshed, minimizing downtime.

Cost Efficiency: Reduced need for frequent sharpening and longer tool life contribute to cost savings.

Enhanced Precision: Consistent cutting performance ensures high machining accuracy, essential for crankshaft production.

Halnn’s indexable crankshaft cutters are renowned for their superior construction and performance. Key features include:

High-Quality Materials: Made from advanced carbide and coated inserts, these tools are designed for durability and precision.

Versatile Applications: Suitable for various crankshaft machining processes, including turning, milling, and cutting.

Precision Engineering: Designed to maintain tight tolerances, ensuring the highest quality in crankshaft production.

Halnn offers a range of indexable crankshaft cutters to meet diverse machining needs:

External Crankshaft Milling Tools: Ideal for machining the outer surfaces of crankshafts, providing excellent surface finish and dimensional accuracy.

Internal Crankshaft Milling Tools: Designed for internal machining tasks, ensuring precise and efficient material removal.

Custom Solutions: Halnn can create bespoke cutting tools tailored to specific customer requirements, ensuring optimal performance for unique applications.

Choosing Halnn’s indexable crankshaft cutters offers numerous benefits:

Increased Productivity: High-speed machining capabilities and quick insert changes keep production lines running smoothly.

Cost Efficiency: Durable materials and replaceable inserts reduce overall tooling costs.

Enhanced Precision: Consistent cutting performance ensures high accuracy, reducing the need for additional finishing processes.

Selecting the right cutter involves considering several factors:

Material: Ensure the cutter material matches the crankshaft material for optimal performance.

Dimensions: Choose the correct size and geometry for the specific machining process.

Machining Process: Select tools that align with the intended machining operations (e.g., turning, milling, cutting).

Halnn provides expert guidance to help you choose the best cutter for your needs, ensuring maximum efficiency and effectiveness.

Halnn’s indexable crankshaft cutters have been successfully implemented across various industries, resulting in significant productivity gains and cost savings. Here are a few examples:

Automotive Manufacturer: Improved machining efficiency by 30%, reducing production time and costs.

Industrial Engine Producer: Enhanced precision and surface finish, minimizing post-machining processes.

Custom Engineering Solutions: Tailored tools that met specific customer requirements, providing optimal performance and reliability.

An indexable crankshaft cutter is a specialized machining tool designed for precision cutting of crankshafts. It features replaceable inserts, known as indexable inserts, which can be easily replaced when worn out, enhancing the tool's lifespan and efficiency.

Traditional cutters require frequent re-sharpening and replacement when they become dull. In contrast, indexable crankshaft cutters have replaceable inserts that can be swapped out quickly, reducing downtime and maintaining consistent cutting performance.

Increased Productivity: Quick replacement of inserts minimizes downtime.

Cost Efficiency: Longer tool life and reduced sharpening costs.

Enhanced Precision: Consistent cutting quality ensures high machining accuracy.

Halnn’s indexable crankshaft cutters are made from high-quality carbide and coated inserts, designed for durability and precision in high-performance machining applications.

Yes, indexable crankshaft cutters are available in designs suitable for both external and internal machining tasks, providing versatility and flexibility in various machining operations.

Selecting the right cutter involves considering the material of the crankshaft, the dimensions and geometry of the tool, and the specific machining process (e.g., turning, milling, cutting). Halnn provides expert guidance to help you choose the best tool for your needs.

Regular inspection and timely replacement of the inserts are essential to maintain optimal performance. Ensuring the cutter is clean and properly stored when not in use also helps extend its lifespan.

Yes, Halnn offers custom solutions tailored to specific customer requirements, ensuring optimal performance for unique machining challenges.

The ability to quickly replace worn inserts reduces downtime and maintains a high level of cutting performance, leading to faster machining cycles and improved overall efficiency.

Halnn’s indexable crankshaft cutters can be purchased directly through Halnn's website or by contacting their sales team for detailed information and personalized assistance.

Indexable crankshaft cutters are widely used in the automotive, aerospace, and industrial manufacturing industries, where precision and efficiency in crankshaft machining are crucial.

The precision engineering and consistent performance of indexable crankshaft cutters ensure tight tolerances and excellent surface finishes, reducing the need for additional finishing processes and improving the overall quality of the finished product.

To learn more about Halnn’s indexable crankshaft cutters or to request a quote, visit our [website](https://www.halnncbn.com/) or contact our expert team today. Discover the difference Halnn can make in your machining operations.

Mail address: halnntools@halnn-group.com

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.