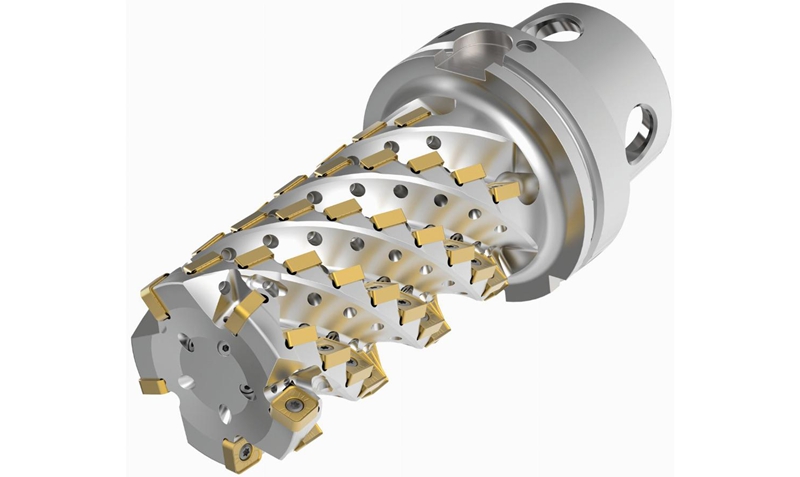

An indexable gear cutting tool is designed with replaceable inserts, allowing for continuous use and reduced downtime during maintenance. These tools are essential in various manufacturing processes, offering unparalleled precision and efficiency. Unlike traditional gear cutting tools, indexable gear cutting tools provide a flexible and cost-effective solution for producing high-quality gears.

Indexable gear cutting tools significantly enhance production efficiency. The replaceable inserts allow for quick changes without the need for tool regrinding, thus reducing downtime and maintaining consistent production flow.

By utilizing replaceable inserts, manufacturers can reduce the cost associated with tool maintenance and replacement. This leads to long-term savings and improved cost management.

Halnn indexable gear cutting tools are engineered for high precision and consistency, ensuring that each gear produced meets stringent quality standards.

These tools are versatile and can be used in a wide range of applications, including automotive, aerospace, and heavy machinery industries.

These cutters are used for creating gear teeth profiles through milling operations. Halnn indexable gear milling cutters are designed for optimal performance and longevity.

Ideal for continuous gear production, indexable gear hobbing cutters by Halnn provide excellent surface finish and dimensional accuracy.

Perfect for shaping internal and external gear profiles, these tools offer high precision and are suitable for complex gear geometries.

Comprehensive tools designed for various gear machining processes, providing flexibility and efficiency in manufacturing operations.

Halnn employs advanced materials and cutting-edge technology in the production of its indexable gear cutting tools. High-quality carbide inserts ensure durability and superior cutting performance. Innovative geometrical designs and coatings enhance tool life and reduce cutting forces.

Used extensively in the production of transmission gears, differentials, and other critical components.

Vital for manufacturing high-precision gears used in aircraft engines and navigation systems.

Essential for creating robust gears for construction equipment, industrial machines, and other heavy-duty applications.

Halnn offers custom solutions tailored to specific industry needs, ensuring optimal performance and efficiency.

When selecting an indexable gear cutting tool, consider the material of the workpiece, gear type, production volume, and specific application requirements.

Consult with Halnn experts to choose the appropriate tool that meets your production needs and ensures maximum efficiency and cost-effectiveness.

Regular inspection and proper maintenance of tools ensure their longevity and optimal performance. Clean and store tools properly to avoid damage.

Follow best practices for tool usage, such as using the correct cutting parameters and ensuring proper coolant application to maximize tool life.

Address common issues such as insert wear or breakage promptly to maintain production efficiency and product quality.

Explore how Halnn indexable gear cutting tools have transformed manufacturing processes for various clients, improving efficiency and product quality.

Hear from satisfied customers about their experiences with Halnn cutting tools and the benefits they have realized.

Review documented improvements in production metrics and cost savings achieved by clients using Halnn tools.

With years of experience and a solid reputation, Halnn is a trusted provider of high-quality cutting tools.

Halnn tools offer superior performance, durability, and cost-effectiveness, making them a preferred choice in the industry.

Continuous innovation and commitment to customer satisfaction set Halnn apart as a leader in cutting tool technology.

In summary, indexable gear cutting tools by Halnn provide unmatched efficiency, precision, and versatility, making them an essential component in modern manufacturing processes. Whether you are in the automotive, aerospace, or heavy machinery industry, Halnn cutting tools can help you achieve your production goals with excellence.

An indexable gear cutting tool is a type of cutting tool designed with replaceable inserts, allowing for continuous use without the need for tool regrinding. These tools are used in various gear manufacturing processes, providing precision and efficiency.

Efficiency and Productivity: Quick insert changes reduce downtime.

Cost-Effectiveness: Replaceable inserts lower maintenance and replacement costs.

Precision and Consistency: High-quality inserts ensure consistent gear production.

Versatility: Suitable for a wide range of gear machining applications.

Indexable Gear Milling Cutters: For creating gear teeth profiles.

Indexable Gear Hobbing Cutters: Ideal for continuous gear production.

Indexable Gear Shaper Cutters: For shaping internal and external gear profiles.

Indexable Gear Machining Tools: Comprehensive tools for various gear machining processes.

Indexable gear milling cutters are specifically designed for milling operations, providing high precision and flexibility with replaceable inserts. They offer efficient metal removal rates and longer tool life compared to traditional fixed-geometry tools.

Halnn uses high-quality carbide inserts for durability and superior cutting performance. Advanced coatings and geometrical designs enhance tool life and reduce cutting forces.

Automotive: Production of transmission gears and differentials.

Heavy Machinery: Creating robust gears for construction equipment and industrial machines.

Custom Applications: Tailored solutions for specific industry needs.

Consider the material of the workpiece, gear type, production volume, and specific application requirements. Consulting with Halnn experts can help you select the appropriate tool for your needs.

Regular inspection, proper cleaning, and correct storage are essential to maintain tool longevity and performance. Following best practices for tool usage, such as using correct cutting parameters and proper coolant application, can also help maximize tool life.

Common issues like insert wear or breakage should be addressed promptly. Consult Halnn support team for troubleshooting assistance and recommendations on best practices to maintain production efficiency and product quality.

Halnn offers high-quality cutting tools designed for superior performance, durability, and cost-effectiveness. With years of experience and a commitment to innovation, Halnn provides reliable solutions that enhance manufacturing processes across various industries.

For more detailed information or specific inquiries, contact Halnn today to learn how our indexable gear cutting tools can benefit your production operations.

Our website: https://www.halnncbn.com/

Mail address: halnntools@halnn-group.com

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.