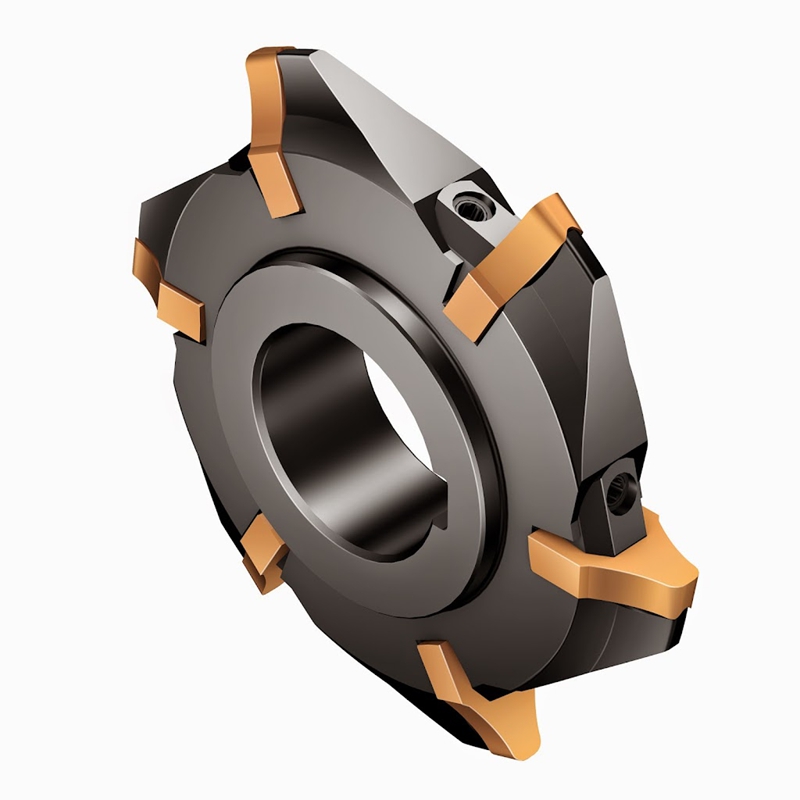

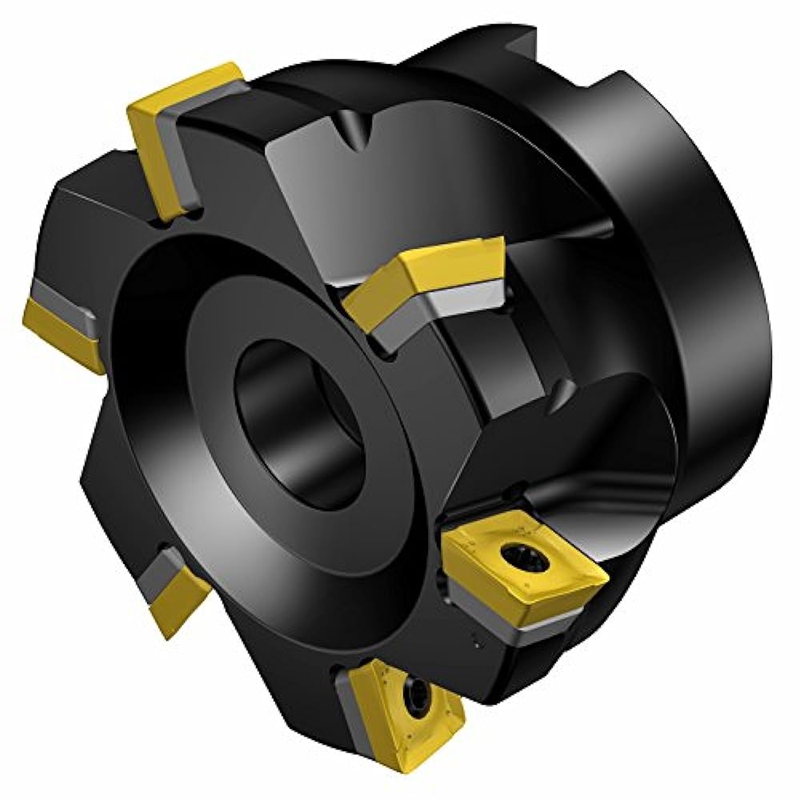

In the realm of gear manufacturing, precision and efficiency are paramount. One tool that has revolutionized this field is the indexable gear milling cutter. This article delves into the intricacies of these advanced tools, their benefits, and their applications. Halnn, a leading name in cutting tool technology, offers an extensive range of indexable gear milling cutters designed to meet the highest standards of performance and durability.

An indexable gear milling cutter is a tool designed for cutting gears with high precision and efficiency. Unlike traditional milling cutters, these tools feature replaceable inserts, which allow for continuous cutting without the need for resharpening. This design enhances the tool's versatility and longevity, making it a preferred choice for modern gear manufacturing.

Indexable gear milling cutters boast several key features that set them apart:

High Cutting Speeds: These cutters are designed to operate at high speeds, significantly reducing production time.

Extended Tool Life: The replaceable inserts mean the tool body lasts longer, as only the worn inserts need to be replaced.

Precision and Accuracy: The advanced design ensures that each gear tooth is cut with high precision, maintaining consistent quality.

Versatility: Suitable for a variety of materials and gear profiles, making them ideal for diverse applications.

Adopting indexable gear milling cutters offers numerous benefits:

Cost-Efficiency: Reduced need for sharpening and longer tool life lead to lower overall costs.

Increased Productivity: Higher cutting speeds and less downtime translate to more gears produced in less time.

Enhanced Gear Quality: Consistent precision cutting improves the quality and performance of the gears.

Flexibility: Capable of handling different gear sizes and profiles with ease.

These cutters are widely used across various industries, including:

Automotive Industry: For manufacturing transmission gears and other precision components.

Heavy Machinery Manufacturing: Suitable for large, high-strength gears used in industrial machinery.

Other Industries: Including wind energy, marine, and rail, where precision gears are crucial.

Halnn, a pioneer in cutting tool technology, offers a comprehensive range of indexable gear milling cutters tailored to meet diverse industrial needs. Our products stand out due to:

Advanced Design: Incorporating the latest technological advancements to ensure superior performance.

High-Quality Materials: Using the best materials to enhance tool life and cutting efficiency.

Customer-Centric Approach: Customized solutions to meet specific requirements of our clients.

Proven Track Record: Numerous successful case studies and positive customer testimonials.

Selecting the appropriate cutter involves considering several factors:

Material: Different materials require specific types of inserts for optimal performance.

Gear Size and Profile: The cutter must be capable of handling the specific dimensions and profiles required.

Precision Requirements: Higher precision applications necessitate cutters with tighter tolerances.

To maximize the lifespan and performance of your indexable gear milling cutters, follow these maintenance tips:

Proper Handling and Storage: Keep tools in a dry, clean environment to prevent damage and corrosion.

Regular Maintenance Schedules: Inspect and replace inserts regularly to ensure consistent performance.

Optimal Usage: Follow recommended cutting speeds and feeds to prevent excessive wear.

The field of gear milling is continually evolving. Future trends include:

Innovative Materials: Development of new materials for inserts to extend tool life and performance.

CNC and Automation: Advances in CNC technology and automation will further enhance precision and efficiency.

AI and Machine Learning: These technologies will enable smarter, more adaptive cutting processes, reducing errors and improving quality.

A: An indexable gear milling cutter is a specialized tool used for cutting gears. It features replaceable inserts, allowing for continuous operation without the need for resharpening. This design enhances efficiency, precision, and tool life.

A: The benefits include higher cutting speeds, extended tool life due to replaceable inserts, cost-efficiency, increased productivity, and improved gear quality. Additionally, these cutters offer versatility, handling various materials and gear profiles.

A: These cutters allow for higher cutting speeds and reduce downtime associated with tool maintenance, such as resharpening. This leads to more gears being produced in less time, significantly boosting productivity.

A: Industries that commonly use these cutters include automotive, aerospace, heavy machinery manufacturing, and others like wind energy, marine, and rail, where precision gears are crucial.

A: To choose the right cutter, consider the material to be cut, the size and profile of the gears, and the precision requirements. Consulting with a cutting tool specialist, like those at Halnn, can help you select the best tool for your needs.

A: Proper handling and storage, regular inspection and replacement of inserts, and following recommended cutting speeds and feeds are essential maintenance practices. This ensures optimal performance and prolongs tool life.

A: Yes, specific types of indexable gear milling cutters are designed for rough milling, while others are optimized for finish milling. It’s important to select the appropriate cutter for each stage of the gear manufacturing process.

A: These cutters are suitable for a variety of materials, including steel, stainless steel, and cast iron. The choice of insert material and coating can be tailored to optimize performance for specific materials.

A: The precision design of these cutters ensures consistent tooth profile and surface finish, which are critical for the performance and longevity of gears. The ability to replace inserts also maintains cutting accuracy over time.

A: Advancements include the development of new insert materials and coatings for longer tool life, integration with CNC and automation technologies for improved precision, and the use of AI and machine learning for smarter cutting processes.

A: Halnn offers advanced design, high-quality materials, and a customer-centric approach. With a proven track record and a range of customized solutions, Halnn ensures you get the best tools for your gear manufacturing needs.

For more information or to explore Halnn range of indexable gear milling cutters, visit our website or contact our sales team.

Indexable gear milling cutters represent a significant advancement in gear manufacturing technology, offering unparalleled efficiency, precision, and cost-effectiveness. Halnn is at the forefront of this innovation, providing top-quality tools tailored to meet the evolving needs of the industry. For more information or to explore our range of products, visit Halnn website or contact our sales team.

By integrating the latest advancements and maintaining a customer-centric approach, Halnn continues to lead the way in cutting tool technology, ensuring our clients achieve the highest standards of gear manufacturing.

Our website: https://www.halnncbn.com/

Mail address: halnntools@halnn-group.com

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.