In the fast-paced world of gear manufacturing, efficiency and precision are paramount. Hobs with indexable carbide inserts have emerged as a groundbreaking solution, offering superior performance and cost-effectiveness. Halnn, a leader in cutting tool innovation, is at the forefront of this technological advancement.

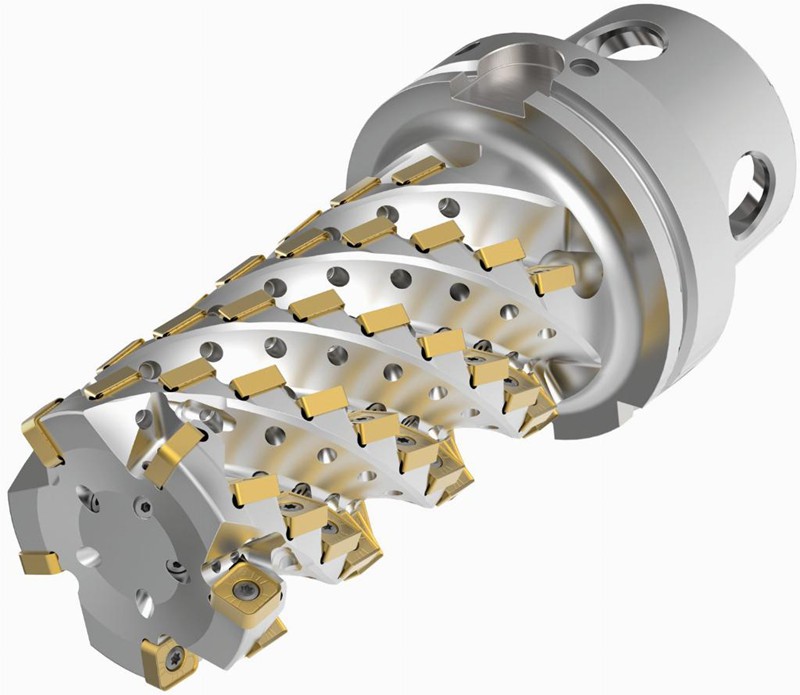

Hobs with indexable carbide inserts are designed for high-precision gear cutting. Unlike traditional hobs, which require entire tool replacement when worn, these hobs feature replaceable inserts made from durable carbide materials. This not only extends the tool's lifespan but also enhances cutting accuracy.

One of the primary benefits of these hobs is their longevity. Carbide inserts are known for their durability, which significantly reduces the frequency of replacements. This translates to cost savings over time.

The replaceable nature of the inserts means that only the worn part needs to be replaced, rather than the entire hob. This reduces both material costs and downtime, further improving cost efficiency.

The precision of these hobs ensures high-quality gear production, meeting the stringent demands of modern manufacturing. The use of indexable inserts allows for consistent performance, leading to fewer defects and higher productivity.

Easy replacement of the inserts means that production interruptions are minimized, ensuring that operations run smoothly and efficiently.

Hobs with indexable carbide inserts are invaluable in industries such as automotive, aerospace, and heavy machinery. They are particularly effective in manufacturing gears for high-stress applications, where precision and durability are critical.

In the automotive industry, the demand for high-precision gears is constant. Hobs with indexable carbide inserts help manufacturers meet these requirements efficiently, ensuring high performance and reliability in vehicles.

For heavy machinery, durability is key. Hobs with indexable carbide inserts provide the strength and longevity needed to produce gears that can handle heavy loads and prolonged use.

Recent advancements have focused on improving the materials and coatings used in carbide inserts. Innovations such as multi-layer coatings enhance the inserts' resistance to wear and heat, further boosting their performance and lifespan. Additionally, improvements in hob design have led to more efficient and precise gear cutting processes.

Advanced coatings such as TiN (Titanium Nitride) and AlTiN (Aluminum Titanium Nitride) improve the hardness and heat resistance of the inserts, making them more effective for high-speed cutting.

Modern hob designs incorporate better chip evacuation and enhanced stability, leading to smoother and more precise cutting operations.

Choosing the right hob depends on several factors, including the material of the workpiece, the required gear specifications, and the specific application. Halnn offers a range of customizable options to meet diverse manufacturing needs, ensuring optimal performance and efficiency.

Material Compatibility: Ensure the hob is suitable for the material being machined.

Gear Specifications: Select a hob that meets the precise specifications of the gears being produced.

Application Requirements: Consider the specific needs of the application, such as speed and load requirements.

Proper maintenance is crucial to maximizing the lifespan of hobs with indexable carbide inserts. Regular inspection and timely replacement of worn inserts are essential. Additionally, following best practices such as using appropriate cutting speeds and feeds can enhance performance.

Regular Inspections: Frequently check the condition of the inserts and replace them when signs of wear are evident.

Optimal Cutting Conditions: Use the recommended cutting speeds and feeds to prevent premature wear.

Proper Storage: Store the hobs and inserts in a clean, dry environment to prevent corrosion and damage.

Many companies have experienced significant benefits from switching to hobs with indexable carbide inserts. For instance, an automotive manufacturer reported a 30% increase in production efficiency and a 20% reduction in tooling costs after implementing Halnn’s solutions.

A leading automotive manufacturer was facing issues with tool wear and production delays. By switching to Halnn’s hobs with indexable carbide inserts, they saw a significant improvement in tool life and production speed, leading to reduced costs and higher product quality.

Halnn is dedicated to pushing the boundaries of gear manufacturing technology. Our commitment to quality and innovation is reflected in our range of hobs with indexable carbide inserts. Designed to meet the highest standards, our products deliver unparalleled performance and reliability. Customers worldwide trust Halnn to provide cutting-edge solutions that drive their success.

Quality Assurance: Every product undergoes rigorous testing to ensure it meets our high standards.

Customer Support: We offer comprehensive support and guidance to help our customers achieve the best results.

Innovation: We continuously invest in research and development to bring the latest advancements to our customers.

Hobs with indexable carbide inserts are specialized gear cutting tools that feature replaceable carbide inserts. These inserts can be indexed, or rotated, to present a fresh cutting edge when one becomes worn, thus extending the tool's life and maintaining cutting performance.

Traditional hobs are typically made from high-speed steel and require re-sharpening or replacement when worn. Hobs with indexable carbide inserts use durable carbide material inserts that can be easily replaced without discarding the entire hob, resulting in reduced downtime and cost savings.

The primary benefits include longer tool life, consistent cutting performance, reduced downtime due to easy insert replacement, and overall cost efficiency. Carbide inserts also offer superior hardness and wear resistance compared to traditional materials.

These hobs are widely used in industries such as automotive and heavy machinery manufacturing, where precision and durability in gear production are critical.

Yes, they are suitable for various gear types, including spur gears, helical gears, and worm gears. However, selecting the appropriate insert geometry and coating is crucial to achieving optimal performance for specific gear types and materials.

Factors to consider include the material of the workpiece, gear specifications, cutting conditions, and the required precision and finish. Consulting with the manufacturer, like Halnn, can help determine the best tool for your specific needs.

Regular inspection for wear and timely replacement of inserts are essential. Additionally, maintaining optimal cutting conditions and following the manufacturer’s recommendations for speeds and feeds can prolong the tool’s life and performance.

While they offer numerous benefits, these hobs may have higher initial costs compared to traditional hobs. Additionally, ensuring proper setup and alignment is critical to prevent damage to the inserts and ensure precise cutting.

Recent advancements include improved carbide grades, advanced coatings such as TiN and AlTiN for enhanced wear resistance, and optimized hob designs for better chip evacuation and stability during cutting.

You can contact Halnn directly through their website or sales representatives to discuss your specific needs and receive expert recommendations on the best hobs for your applications. Halnn offers a range of customizable options to meet diverse manufacturing requirements.

Hobs with indexable carbide inserts represent the future of gear manufacturing, offering unmatched precision, efficiency, and cost-effectiveness. Halnn is proud to lead this transformation, providing top-of-the-line products and exceptional service. Explore our offerings and discover how we can help you achieve excellence in gear production.

Our website: https://www.halnncbn.com/

Mail address: halnntools@halnn-group.com

WhatsApp: +8615515925975

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.