In the ever-evolving world of precision machining, the need for flexible, efficient, and high-precision tooling systems is paramount. One such innovation that has set a new standard in the industry is Capto modular tooling. This article will delve into the various aspects of Capto modular tooling, its benefits, applications, and why Halnn, a leader in tooling solutions, should be your go-to provider for these advanced systems.

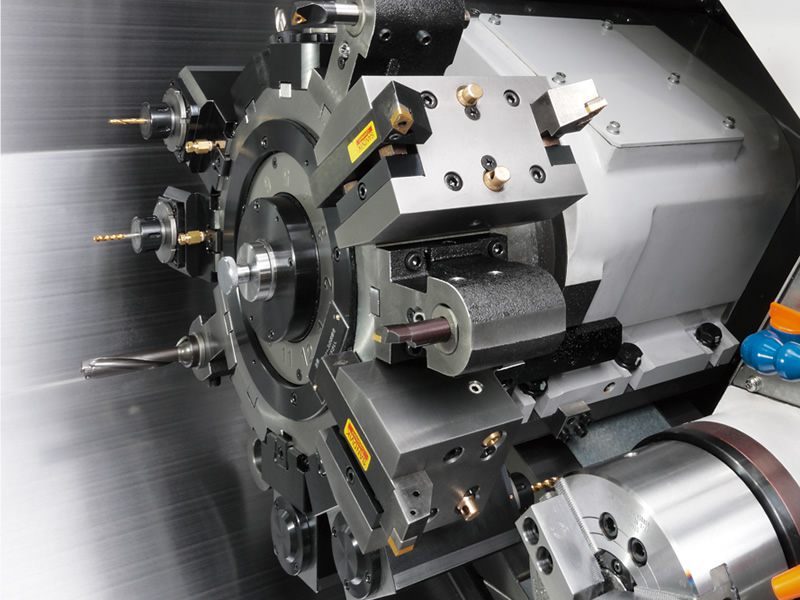

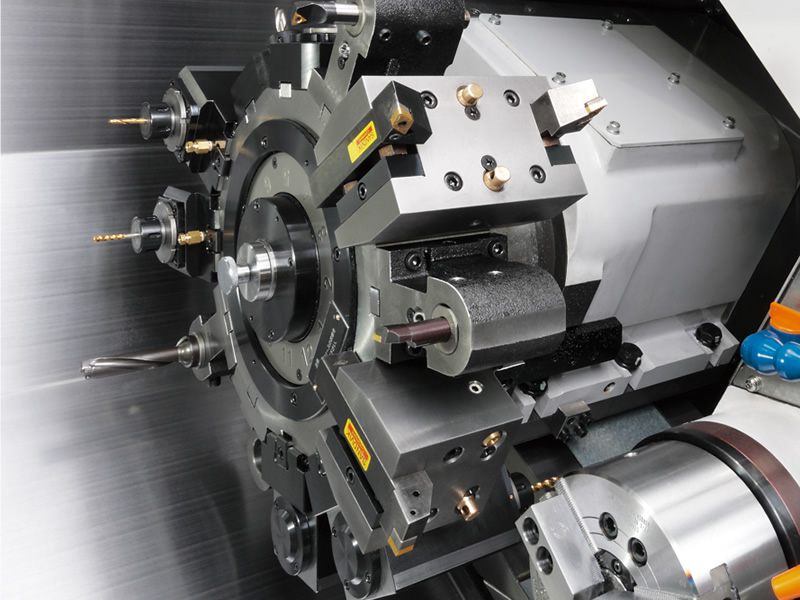

Capto modular tooling is a versatile and innovative tooling system designed to enhance the efficiency and precision of machining processes. Characterized by its polygonal shank design, Capto tooling systems are known for their high rigidity, modularity, and quick-change capabilities. These features make them suitable for a wide range of machining operations, from turning and milling to drilling and boring.

Capto modular tooling systems are designed to be highly adaptable. The modular nature allows for quick and easy changes between different tools, reducing downtime and increasing productivity. This flexibility is essential in modern machining environments where rapid adjustments are often required.

The polygonal shank interface of Capto tools ensures a high level of precision and stability during machining. This design minimizes vibrations and enhances the accuracy of the machining process, resulting in superior surface finishes and tighter tolerances.

One of the standout features of Capto modular tooling is its quick-change capability. This feature allows operators to switch tools swiftly, significantly reducing setup times and improving overall workflow efficiency.

Capto modular tooling is compatible with a variety of machines and operations. Whether you are performing turning, milling, or drilling, Capto tools can be seamlessly integrated into your existing setup.

The quick-change capability and modular design of Capto tools mean less downtime and more time spent on actual machining. This efficiency translates to higher productivity and reduced operational costs.

Traditional tooling systems often require lengthy setup and adjustment times. Capto modular tooling systems, with their easy-to-change design, minimize these times, allowing for more streamlined operations.

The high precision and stability of Capto tools reduce wear and tear, extending the life of the tools. This longevity makes them a cost-effective choice in the long run, as fewer replacements are needed.

The stability and precision of Capto modular tooling ensure that the final product meets the highest standards of accuracy and surface finish. This quality is crucial in industries where precision is non-negotiable.

Capto modular tooling systems are versatile and can be used in various machining operations:

Capto tools are ideal for turning operations, providing high precision and stability.

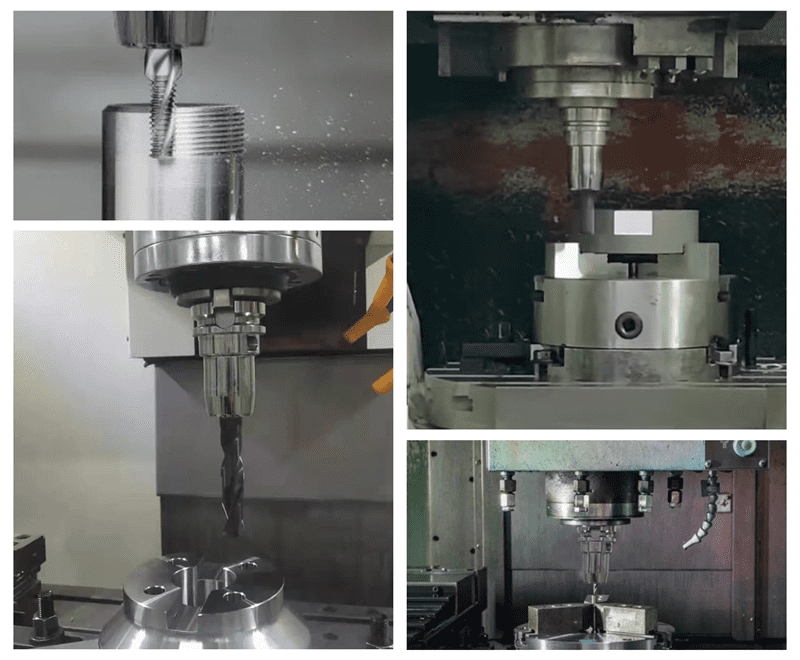

The modularity and rigidity of Capto tools make them perfect for milling tasks, ensuring smooth and accurate cuts.

Capto modular tooling systems enhance drilling operations with their quick-change capabilities and precision.

For boring applications, Capto tools provide the necessary stability and accuracy to achieve the desired results.

Capto modular tooling is widely used in automotive, aerospace, and other industries where precision and efficiency are critical.

Capto modular tooling systems offer several advantages over traditional systems, including quicker tool changes, higher precision, and improved stability.

While both Capto and HSK tooling systems are highly regarded, Capto's polygonal shank design often provides superior rigidity and stability, making it a preferred choice in many applications.

Capto modular tooling stands out for its versatility, precision, and efficiency, making it an excellent investment for any machining operation.

Halnn offers a comprehensive range of Capto modular tooling solutions, designed to meet the diverse needs of modern machining operations.

Halnn provides customization options to tailor Capto tools to your specific requirements, ensuring optimal performance.

Explore success stories and case studies that highlight how Halnn Capto modular tooling solutions have helped clients achieve their machining goals.

Read testimonials from satisfied customers who have experienced the benefits of Halnn Capto modular tooling firsthand.

When selecting Capto modular tooling, consider factors such as material, machine compatibility, and specific application requirements.

Get practical tips on choosing the right Capto tools to meet your machining needs.

Learn how to maintain and care for your Capto tools to ensure longevity and optimal performance.

Stay updated on the latest innovations in Capto tooling technology and how they can benefit your operations.

Discover what the future holds for modular tooling systems and how they will continue to evolve.

Capto modular tooling is a high-precision, quick-change tooling system characterized by its polygonal shank design. It is known for its rigidity, modularity, and versatility, making it suitable for various machining operations, including turning, milling, drilling, and boring.

Capto modular tooling offers several benefits, including:

Quick-change capability: Reduces setup times and increases productivity.

High precision and stability: Ensures superior surface finishes and tighter tolerances.

Modularity: Allows for easy adjustments and tool changes.

Compatibility: Suitable for a wide range of machining operations and machines.

The quick-change capability of Capto modular tooling significantly reduces downtime during tool changes and setups. This efficiency allows for more continuous machining operations, thereby increasing overall productivity.

Yes, Capto modular tooling is highly versatile and can be used in various machining operations, including turning, milling, drilling, and boring. Its design ensures compatibility with a wide range of machines and applications.

Industries such as automotive, aerospace, and precision engineering benefit greatly from Capto modular tooling due to its high precision, quick-change capability, and overall efficiency.

Compared to traditional tooling systems, Capto modular tooling offers superior rigidity, precision, and quick-change capabilities. This results in reduced setup times, increased productivity, and better machining accuracy.

Yes, Capto modular tooling is designed to be compatible with a variety of machines and setups. Its modular design allows for easy integration into existing machining environments.

To ensure optimal performance and longevity, regular maintenance of Capto modular tooling is recommended. This includes cleaning the tool holders, checking for wear and tear, and ensuring proper storage when not in use.

Yes, Halnn offers customization options for Capto modular tooling to meet specific machining requirements. Customized tools can be designed to enhance performance and efficiency for particular applications.

Halnn Capto modular tooling stands out due to its high quality, precision engineering, and the ability to customize tools to specific needs. Halnn commitment to innovation and customer satisfaction makes it a leading provider in the industry.

The polygonal shank design of Capto modular tooling ensures high rigidity and stability during machining operations. This reduces vibrations and enhances accuracy, resulting in superior surface finishes and tighter tolerances.

The quick-change capability of Capto modular tooling allows operators to switch tools swiftly, minimizing downtime and setup times. This feature significantly improves workflow efficiency and productivity.

Yes, there are numerous case studies and success stories showcasing the benefits of Capto modular tooling in various industries. These examples highlight the increased productivity, reduced costs, and superior machining quality achieved with Capto tools.

For more information or to request a quote, you can contact Halnn directly through their website or customer service channels. Halnn team of experts will provide detailed information and assist with your specific needs.

Capto modular tooling is a game-changer in the world of precision machining, offering unparalleled flexibility, precision, and efficiency. Halnn, a leader in tooling solutions, provides a comprehensive range of Capto tools to meet the diverse needs of modern machining operations. By choosing Halnn's Capto modular tooling, you are investing in a solution that will enhance your productivity, reduce costs, and ensure superior machining quality. For more information or to request a quote, contact Halnn today.

Our website: https://www.halnncbn.com/

Mail address: halnntools@halnn-group.com

WhatsApp: +8615515925975

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.