The PSC tool system, also known as the Polygonal Shank Coupling system, has revolutionized the machining industry with its exceptional precision, stability, and quick-change capability. As a leading provider of high-quality machining solutions, Halnn proudly offers advanced PSC tool systems designed to meet the demands of modern manufacturing. This article delves into the features, benefits, and applications of the PSC tool system, providing valuable insights for users and promoting Halnn's cutting-edge products.

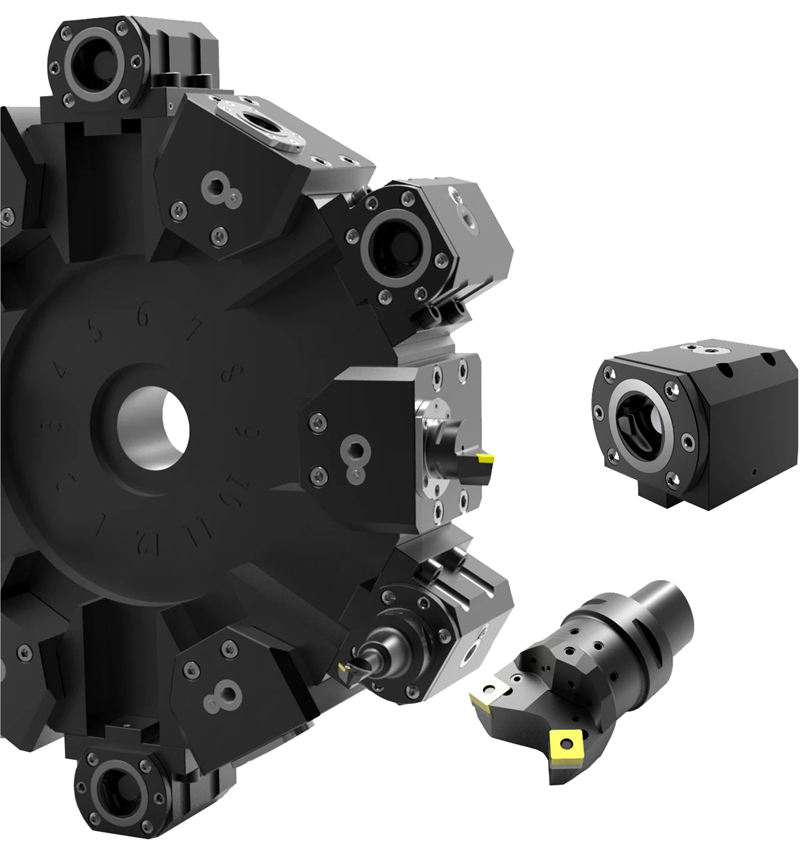

The PSC tool system is a modular tooling system characterized by a polygonal shank coupling interface. This design ensures high rigidity and stability, making it ideal for various machining operations. The PSC system was developed to address the limitations of traditional tool holders, providing enhanced precision, repeatability, and versatility.

Initially developed in Europe, the PSC tool system has been standardized internationally and widely adopted across the machining industry. Its unique design allows for easy integration into existing machine setups, making it a preferred choice for manufacturers seeking to improve productivity and accuracy.

High Rigidity and Stability: The polygonal interface provides superior rigidity, reducing vibrations and improving machining accuracy.

Precision and Accuracy: Enhanced repeatability ensures consistent performance and high-quality results.

Quick-Change Capability: Tools can be changed swiftly, minimizing downtime and increasing efficiency.

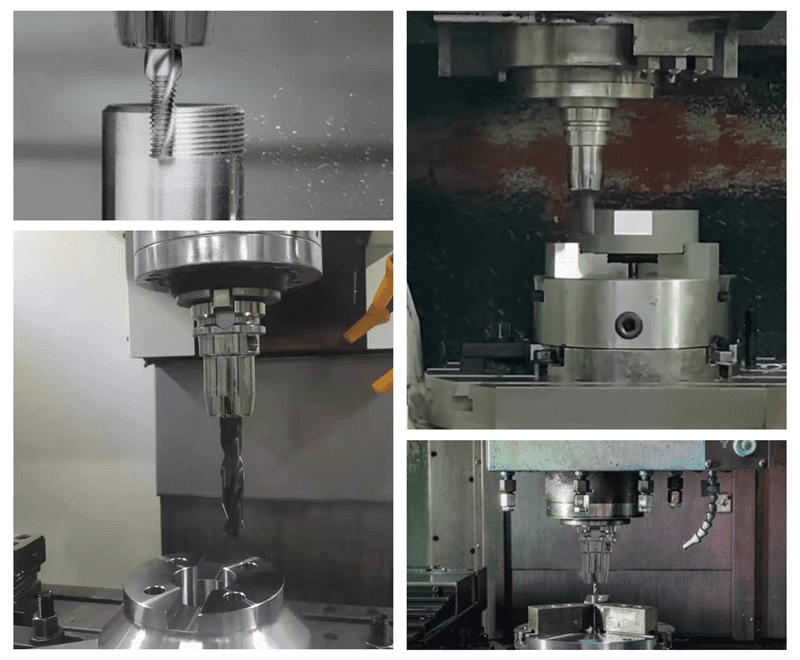

Versatility: Suitable for a wide range of machining applications, from turning and milling to drilling and boring.

Extended Tool Life: Reduced wear and tear on tools result in longer tool life and cost savings.

Modular Design: The modular nature of the PSC system allows for flexible tool configurations, adapting to various machining requirements.

High Torque Transmission: Capable of transmitting high torque, making it suitable for heavy-duty machining tasks.

Precision Coupling: Ensures exact positioning and alignment, crucial for high-precision operations.

Robust Construction: Built to withstand demanding industrial environments, providing durability and reliability.

Halnn offers a comprehensive range of PSC tool systems tailored to different machining needs:

PSC Turning Tools: Designed for high-precision turning operations, these tools provide exceptional stability and accuracy.

PSC Milling Tools: Ideal for complex milling tasks, offering high rigidity and precise control.

PSC Drilling and Boring Tools: Ensuring accurate hole-making with minimal deflection and superior finish.

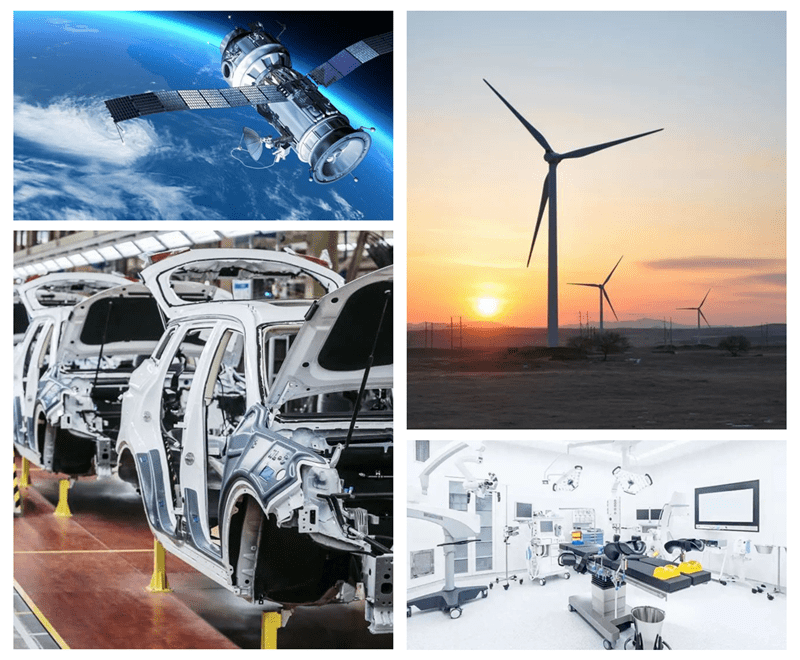

The versatility of the PSC tool system makes it suitable for various industries, including automotive, aerospace, and general manufacturing. Here are some notable applications:

Automotive Industry: Used in the production of engine components, transmission parts, and chassis elements, ensuring high precision and efficiency.

Aerospace Industry: Essential for machining critical aircraft parts, providing the necessary accuracy and reliability.

General Manufacturing: Applicable in a wide range of manufacturing processes, from small-scale workshops to large industrial setups.

Halnn's PSC tool systems have been successfully implemented in numerous projects, resulting in improved productivity and reduced costs. For instance, a leading automotive manufacturer reported a 20% increase in machining efficiency after switching to Halnn's PSC turning tools.

Choosing Halnn's PSC tool system offers several advantages:

Superior Quality: Halnn's tools are manufactured to the highest standards, ensuring reliability and performance.

Innovative Designs: Continuous research and development result in cutting-edge tool solutions.

Customer Support: Dedicated support and service teams provide assistance with tool selection, installation, and maintenance.

Competitive Pricing: Cost-effective solutions without compromising on quality.

Selecting the right PSC tool system involves considering several factors:

Machining Requirements: Assess the specific needs of your machining operations, including the type of materials and the complexity of tasks.

Machine Compatibility: Ensure the tool system is compatible with your existing machinery.

Tool Life and Maintenance: Evaluate the expected tool life and maintenance requirements.

Cost-Benefit Analysis: Consider the overall cost-effectiveness, including potential savings from increased efficiency and reduced downtime.

1. Preparation: Ensure the machine and tools are clean and free from debris.

2. Alignment: Carefully align the PSC tool with the machine spindle.

3. Coupling: Engage the polygonal shank coupling securely.

4. Calibration: Calibrate the tool to ensure precise positioning.

Regular Inspections: Conduct routine checks for wear and damage.

Cleaning: Keep the tool and machine interface clean to prevent contamination.

Lubrication: Apply appropriate lubricants to maintain smooth operation.

Tool Sharpening: Regularly sharpen or replace cutting edges to maintain performance.

Vibration and Instability: Check for proper coupling and alignment.

Tool Wear: Ensure correct tool usage and maintenance practices.

Precision Loss: Recalibrate the tool and inspect for any damage or wear.

Smart Tooling: Integration of sensors and IoT technology for real-time monitoring and optimization.

Advanced Materials: Development of new materials for improved tool performance and durability.

Automation: Increased use of automation in tool changing and maintenance processes.

The PSC tool system is poised to become even more integral to modern machining, driven by advancements in technology and the increasing demand for high-precision manufacturing.

A PSC (Polygonal Shank Coupling) tool system is a modular tooling system designed for high precision, stability, and quick-change capabilities in machining operations. It features a polygonal shank coupling interface that ensures superior rigidity and accuracy.

The polygonal shank coupling provides high rigidity, reducing vibrations and improving machining accuracy. This results in consistent performance and high-quality results in various machining applications.

High Rigidity and Stability: Ensures reduced vibrations and enhanced machining accuracy.

Quick-Change Capability: Allows for swift tool changes, minimizing downtime and increasing efficiency.

Versatility: Suitable for various machining operations, including turning, milling, drilling, and boring.

Extended Tool Life: Reduced wear and tear on tools, leading to cost savings.

PSC Turning Tools: Designed for high-precision turning operations.

PSC Milling Tools: Ideal for complex milling tasks with high rigidity and precise control.

PSC Drilling and Boring Tools: Ensure accurate hole-making with minimal deflection and superior finish.

Consider the specific requirements of your machining operations, machine compatibility, expected tool life, maintenance needs, and overall cost-effectiveness. Assessing these factors will help you choose the most suitable PSC tool system.

PSC tool systems are widely used in various industries, including automotive, aerospace, and general manufacturing. They are essential for high-precision tasks and improving efficiency in these sectors.

1. Preparation: Ensure the machine and tools are clean and free from debris.

2. Alignment: Carefully align the PSC tool with the machine spindle.

3. Coupling: Engage the polygonal shank coupling securely.

4. Calibration: Calibrate the tool to ensure precise positioning.

Regular Inspections: Conduct routine checks for wear and damage.

Cleaning: Keep the tool and machine interface clean to prevent contamination.

Lubrication: Apply appropriate lubricants to maintain smooth operation.

Tool Sharpening: Regularly sharpen or replace cutting edges to maintain performance.

Vibration and Instability: Check for proper coupling and alignment.

Tool Wear: Ensure correct tool usage and maintenance practices.

Precision Loss: Recalibrate the tool and inspect for any damage or wear.

Future trends include the integration of smart tooling with sensors and IoT technology for real-time monitoring, the development of advanced materials for improved tool performance, and increased automation in tool changing and maintenance processes.

Halnn offers superior quality PSC tool systems with innovative designs, dedicated customer support, and competitive pricing. Choosing Halnn ensures reliable performance, enhanced machining capabilities, and improved efficiency in your manufacturing processes.

Yes, PSC tool systems are highly suitable for multi-tasking machines. They provide the necessary rigidity, torque transmission, and precise tool center positioning required for integrating turning and milling operations in a single setup.

The PSC tool system represents a significant advancement in machining technology, offering unparalleled precision, stability, and versatility. Halnn, as a leader in the industry, provides top-quality PSC tool systems designed to meet the evolving needs of manufacturers. By choosing Halnn's PSC tool systems, you can enhance your machining capabilities, reduce costs, and improve overall efficiency.

Website: https://www.halnncbn.com/

Mail address: halnntools@halnn-group.com

WhatsApp: +8615515925975

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.