In the realm of precision machining, controlling vibration is paramount to achieving superior surface finish, dimensional accuracy, and tool longevity. Anti-vibration boring bars are essential tools designed to mitigate the negative effects of vibrations during machining operations. In this article, we will explore the importance and benefits of anti-vibration boring bars, delve into their functionality, and highlight why Halnn's products stand out in this crucial aspect of machining.

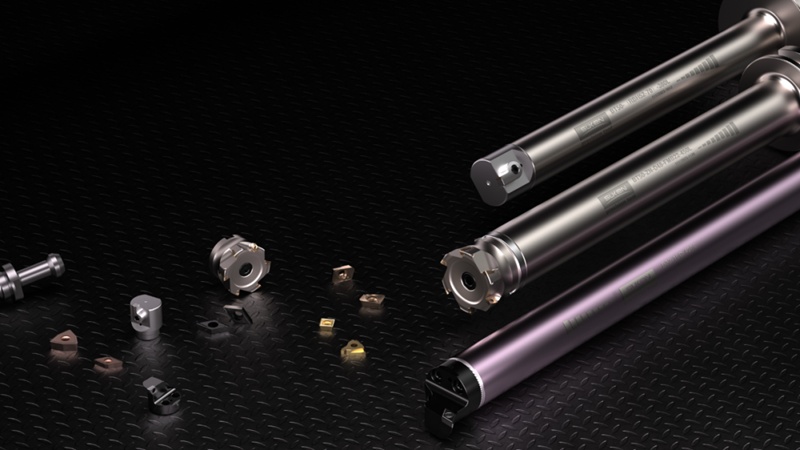

Anti-vibration boring bars are specialized cutting tools engineered to minimize vibrations during boring operations. These bars incorporate advanced damping mechanisms that absorb and neutralize the vibrations generated during machining, ensuring smoother operations and higher precision. Key components typically include a damping element, which can be made of materials like tungsten or polymer, and a robust bar body designed to maximize rigidity.

Improved Surface Finish: By significantly reducing vibrations, these tools produce a smoother surface finish, enhancing the overall quality of the machined part.

Enhanced Dimensional Accuracy: Minimizing vibrations ensures the cutting tool maintains its precise path, leading to higher dimensional accuracy and tighter tolerances.

Increased Tool Life: Vibration reduction decreases wear and tear on the tool, extending its usable life and reducing replacement costs.

Higher Machining Efficiency: With reduced vibrations, cutting speeds can be increased without sacrificing quality, leading to greater productivity.

Reduced Noise Levels: Anti-vibration tools operate more quietly, contributing to a safer and more pleasant working environment.

The core principle behind anti-vibration boring bars is the incorporation of a damping mechanism that counteracts the natural vibrations generated during machining. This mechanism often includes:

Damping Elements: These are typically made from materials that absorb vibrations, such as tungsten, composites, or specialized polymers.

Robust Design: The bar is constructed to be highly rigid, reducing its susceptibility to bending and vibrational forces.

Dynamic Balancing: Some bars are dynamically balanced to further minimize vibrational impact during high-speed operations.

There are various types of anti-vibration boring bars, each tailored to specific applications and machining needs:

Standard Anti-Vibration Boring Bars: Suitable for general-purpose machining.

Heavy-Duty Anti-Vibration Boring Bars: Designed for large-scale, heavy-duty operations.

Custom Anti-Vibration Boring Bars: Tailored to specific requirements, including specialized materials and geometries.

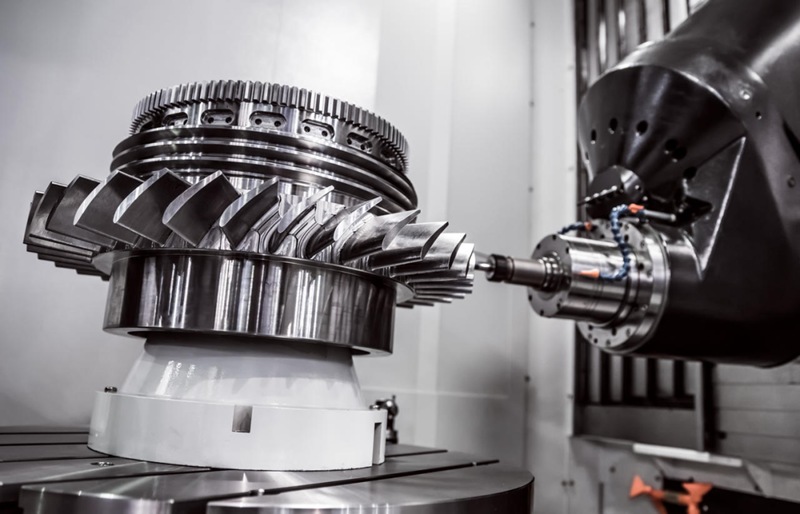

Anti-vibration boring bars are indispensable in industries where precision and surface quality are critical:

Aerospace: Ensuring precision in components subject to extreme conditions.

Automotive: Enhancing the quality and durability of engine parts.

Heavy Machinery: Improving the performance and reliability of large-scale machinery components.

When selecting an anti-vibration boring bar, consider the following factors:

Material Compatibility: Ensure the bar is suitable for the materials being machined.

Size and Length: Choose a bar that fits the specific dimensions and depth requirements of your application.

Damping Efficiency: Opt for a bar with proven damping capabilities to achieve the desired level of vibration control.

To maximize the lifespan and effectiveness of your anti-vibration boring bars, follow these maintenance tips:

Regular Inspections: Check for signs of wear or damage and replace components as needed.

Proper Storage: Store the bars in a dry, secure place to prevent corrosion and physical damage.

Cleaning: Keep the bars clean and free from debris to maintain their performance.

Halnn is a leader in the development and manufacturing of high-performance anti-vibration boring bars. Our products are designed with cutting-edge technology and materials to deliver unparalleled performance. Here's why you should choose Halnn:

Expertise: With years of experience in the industry, Halnn understands the intricacies of vibration control.

Quality: We use only the highest quality materials and adhere to stringent manufacturing standards.

Innovation: Halnn continuously invests in research and development to bring you the latest advancements in machining tools.

Anti-vibration boring bars are vital for achieving superior machining results, enhancing tool life, and improving operational efficiency. Halnn's anti-vibration boring bars are engineered to deliver exceptional performance, making them the ideal choice for your machining needs. Choose Halnn to experience the difference in quality and precision.

A1: Anti-vibration boring bars typically use damping materials such as tungsten, composites, and specialized polymers to absorb and neutralize vibrations.

A2: Consider factors such as material compatibility, size and length requirements, and the damping efficiency needed for your specific application.

A3: Yes, they are designed to handle high-speed machining while maintaining precision and reducing vibrations.

A4: Regular inspections, proper storage, and keeping the bars clean are essential for maintaining their performance and extending their lifespan.

A5: Halnn offers high-quality, innovative products backed by years of industry expertise and a commitment to excellence in machining tools.

Email: halnntools@halnn-group.com

WhatsApp: +8615515925975

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.