In the realm of precision machining, even the slightest vibration can compromise the quality of the final product, leading to increased surface roughness and reduced accuracy. Effective vibration control is paramount, influencing not only the quality and efficiency of machining processes but also the longevity and safety of the equipment used. This article delves into the significance of vibration damped machining tools, focusing on Halnn's innovative solutions designed to enhance machining stability and performance.

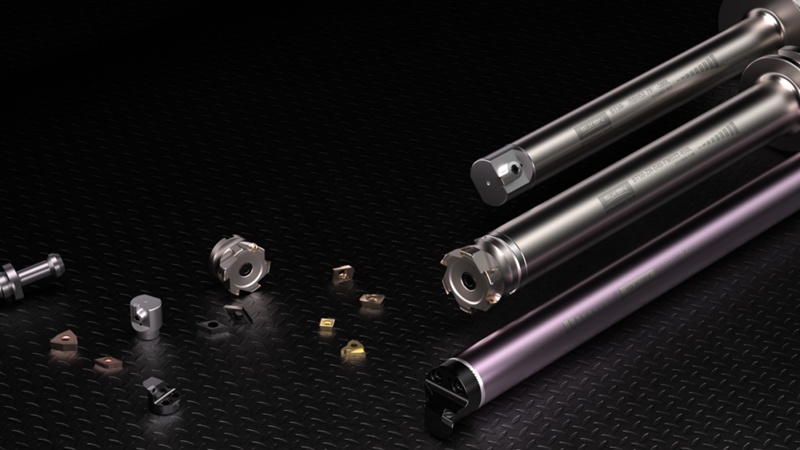

Vibration damped machining tools are specially designed to minimize the impact of vibrations during machining operations. These tools incorporate advanced materials and engineering techniques to absorb and dissipate vibrational energy, ensuring smoother and more precise cutting processes. Common types of vibration damped tools include turning bars, boring bars, and milling cutters, each tailored to specific machining applications.

Vibrations in machining can lead to a host of issues, including poor surface finish, reduced dimensional accuracy, and increased tool wear. By mitigating these vibrations, vibration damped machining tools offer several key benefits:

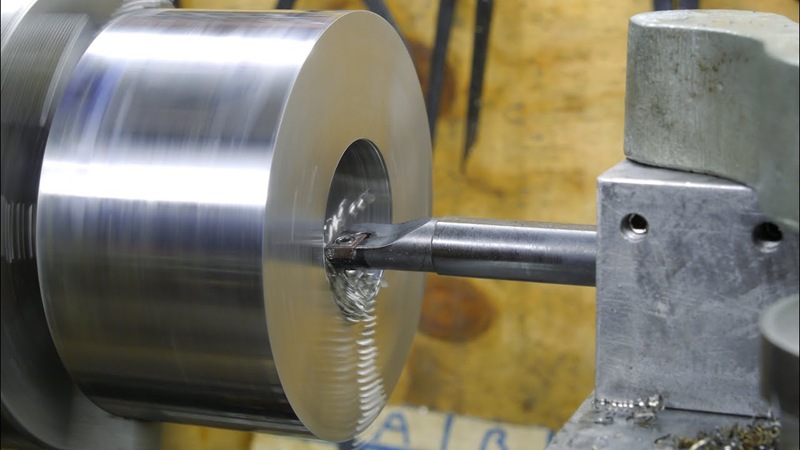

Improved Surface Finish: Smoother cuts result in a finer surface finish, reducing the need for additional finishing processes.

Enhanced Accuracy: Reduced vibrations lead to higher dimensional accuracy, critical in precision machining.

Extended Tool Life: Lower vibrations mean less stress on cutting tools, thereby extending their operational lifespan.

Increased Productivity: With stabilized cutting processes, machining operations can run at higher speeds and feeds, boosting overall productivity.

Halnn's vibration damped machining tools are distinguished by their advanced features:

High-Quality Materials: Utilizing materials with excellent damping properties to absorb vibrational energy effectively.

Innovative Design: Engineered with internal structures that enhance vibration absorption, including viscoelastic materials and tuned mass dampers.

Performance Comparison: Studies and real-world applications demonstrate that Halnn's tools significantly outperform standard machining tools in terms of vibration control and overall machining quality.

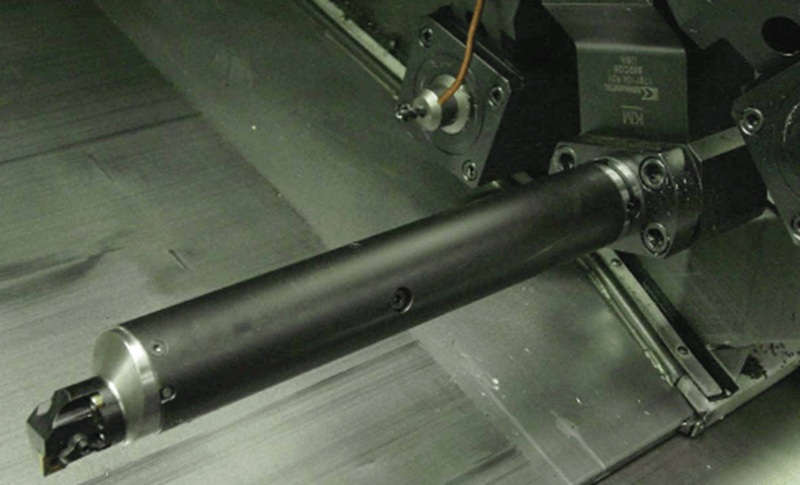

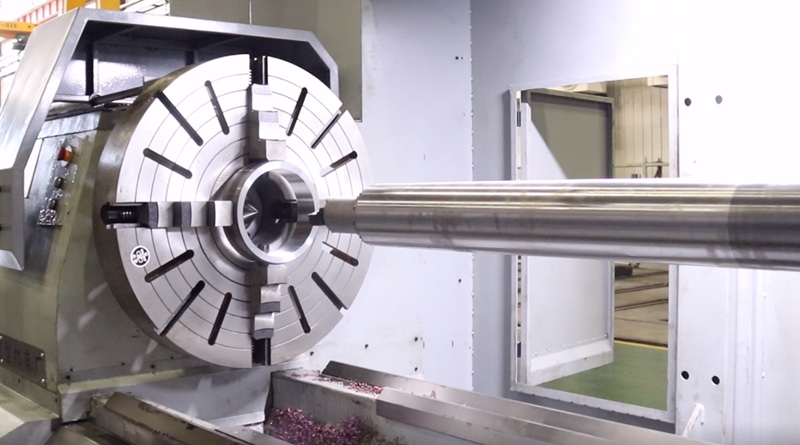

Ideal for deep-hole boring, these bars minimize vibrations to achieve superior surface finish and dimensional accuracy.

Engineered for milling operations, these cutters provide smooth and efficient material removal, even in demanding applications.

Improving the quality and efficiency of engine part manufacturing, leading to higher performance and reliability.

Enhancing precision in machining structural components, which is critical for safety and performance in aerospace applications.

Reducing defects in high-precision parts, contributing to overall product quality and operational efficiency.

Halnn is at the forefront of developing vibration damped machining tools, offering a range of products designed to meet diverse machining needs. Our tools are characterized by:

Proprietary Technologies: Incorporating unique engineering solutions that set our products apart.

Customer Satisfaction: Testimonials from satisfied clients underline the reliability and performance of Halnn's tools.

Product Range: From turning bars to milling cutters, Halnn provides comprehensive solutions for various machining operations.

When selecting a vibration damped machining tool, consider the following factors:

Material Compatibility: Ensure the tool is suited for the material being machined.

Application Type: Choose the right tool type (turning, boring, milling) based on the specific operation.

Machine Specifications: Verify that the tool is compatible with your machining equipment.

Decision-Making Checklist: Use a systematic approach to evaluate your options and make an informed choice.

To maximize the performance and lifespan of vibration damped machining tools, follow these guidelines:

Proper Usage: Adhere to recommended cutting parameters and tool handling practices.

Regular Maintenance: Conduct routine inspections and maintenance to keep the tools in optimal condition.

Troubleshooting: Address common issues promptly to avoid compromising machining quality.

A1: Vibration damped machining tools are specially designed cutting tools that incorporate materials and engineering techniques to reduce or eliminate vibrations during machining operations. This leads to improved surface finish, higher dimensional accuracy, and longer tool life.

A2: Vibration damping is crucial in machining because it helps prevent surface roughness, inaccuracies, and premature tool wear. Reducing vibrations ensures smoother cuts, better precision, and increased productivity, resulting in higher-quality finished products.

A3: Vibration damped machining tools work by incorporating internal structures and materials with high damping properties. These features absorb and dissipate vibrational energy, stabilizing the cutting process and minimizing the impact of vibrations on the tool and workpiece.

A4: The main types of vibration damped machining tools include turning bars, boring bars, and milling cutters. Each type is designed to address specific machining operations, providing stability and precision for various applications.

A5: Vibration damped turning bars offer several benefits, including improved surface finish, enhanced accuracy, and extended tool life. They stabilize the turning process, allowing for higher speeds and feeds, which increases overall productivity.

A6: Yes, vibration damped boring bars are particularly effective for deep-hole boring. Their ability to minimize vibrations ensures superior surface finish and dimensional accuracy, even in challenging deep-hole applications.

A7: Vibration damped milling cutters provide smooth and efficient material removal, reducing the likelihood of defects and improving the overall quality of the machined part. They are ideal for high-precision and high-speed milling operations.

A8: Industries such as automotive, aerospace, and general manufacturing benefit significantly from vibration damped machining tools. These tools enhance the precision and efficiency of machining operations, leading to higher-quality products and reduced production costs.

A9: When selecting a vibration damped machining tool, consider factors such as the material being machined, the specific machining operation (turning, boring, milling), machine specifications, and compatibility with your equipment. Consulting with experts or the tool manufacturer can help ensure you make the right choice.

A10: Regular maintenance of vibration damped machining tools includes routine inspections, proper usage according to recommended cutting parameters, and addressing any issues promptly. Following these practices helps maintain tool performance and extend its operational lifespan.

A11: Halnn's vibration damped machining tools are distinguished by their advanced materials, innovative design, and superior damping properties. They offer unparalleled performance in reducing vibrations, enhancing machining stability, and improving overall product quality.

A12: Halnn's vibration damped machining tools can be purchased directly through our website or by contacting our sales team. We provide comprehensive support to help you select the right tools for your specific machining needs.

A13: While vibration damped machining tools may have a higher initial cost than standard tools, their benefits in terms of improved machining quality, extended tool life, and increased productivity often result in significant cost savings over time.

A14: Vibration damped tools are compatible with a wide range of machining equipment. However, it's essential to verify compatibility with your specific machines and consult with the tool manufacturer for any necessary adjustments or recommendations.

Vibration damped machining tools are essential for achieving precision and efficiency in modern machining operations. Halnn's innovative solutions offer unmatched performance, helping manufacturers enhance product quality and operational efficiency. By choosing Halnn's vibration damped machining tools, you invest in cutting-edge technology that drives success in your machining endeavors. Explore our product offerings and contact us for more information on how we can support your machining needs.

Halnn is committed to providing high-quality, reliable, and innovative machining solutions. Partner with us to experience the benefits of our advanced vibration damped machining tools and elevate your machining processes to new heights.

Our website: https://www.halnncbn.com/

Email: halnntools@halnn-group.com

WhatsApp: +8615515925975

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.