In the world of precision machining, valve body honing reamers are indispensable tools that play a crucial role in ensuring the optimal performance and longevity of valves. At Halnn, we specialize in providing high-quality valve body honing reamers that meet the exacting standards of various industries. This article delves into the intricacies of valve body honing reamers, highlighting their importance, types, benefits, and Halnn's superior offerings.

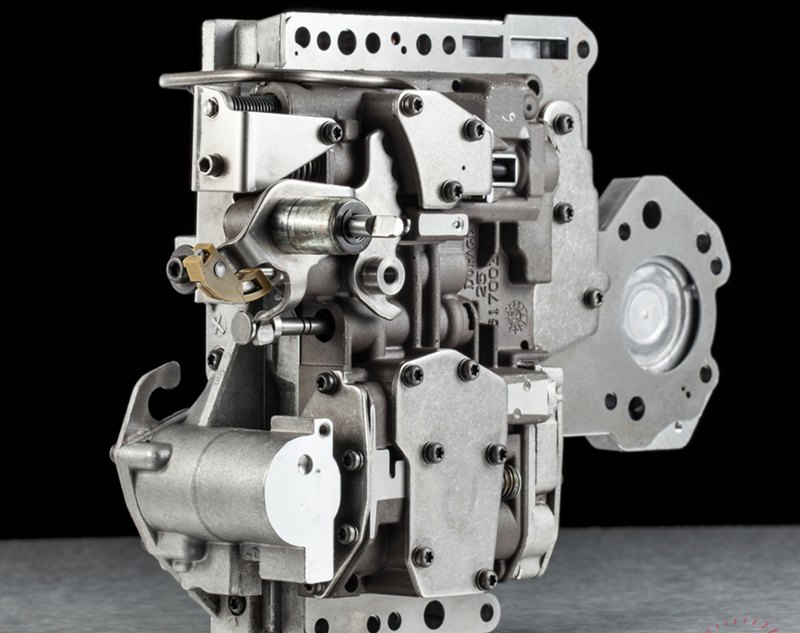

A valve body honing reamer is a precision tool designed to finish the inner surfaces of valve bodies to achieve a high degree of accuracy and smoothness. These tools are essential in applications where tight tolerances and excellent surface finishes are required, such as in the automotive, hydraulic, and aerospace industries.

Material: Typically made from high-quality steel or carbide and coated with diamond for enhanced durability.

Design: Includes adjustable or stationary blades to cater to different precision levels and application needs.

Precision: Capable of achieving micron-level accuracy for superior surface finishes.

Precision is paramount in valve body honing as it directly impacts the performance, efficiency, and lifespan of valves. Proper honing reduces friction, wear, and tear, ensuring that valves operate smoothly and reliably. This precision is especially crucial in industries where valves play a critical role in system safety and functionality.

Stationary Diamond Reamers: Ideal for specific, repeatable tasks where the dimensions do not change frequently.

Adjustable Diamond Honing Reamers: Provide flexibility to accommodate various sizes and are suitable for applications requiring different tolerances.

Diamond Honing Reamers: Known for their exceptional hardness and durability, providing superior surface finishes and longer tool life.

Other Abrasive Materials: Include silicon carbide, aluminum oxide, etc., which are used for less demanding applications.

Diamond honing reamers offer unmatched hardness, making them ideal for machining hard materials and ensuring extended tool life.

The use of diamond ensures a smoother surface finish, which is crucial for reducing friction and wear in valve components.

Despite the higher initial cost, diamond honing reamers provide long-term cost savings due to their durability and reduced need for frequent replacements.

At Halnn, we pride ourselves on delivering top-tier valve body honing reamers that cater to a wide range of industrial needs. Our reamers are designed with precision and durability in mind, ensuring that our clients receive the best tools for their applications.

Customization: We offer customized solutions to meet specific client requirements.

Quality Assurance: Each reamer undergoes rigorous quality checks to ensure it meets industry standards.

Innovative Design: Our reamers incorporate the latest technology to enhance performance and efficiency.

Used extensively in the manufacturing of engine components, transmission parts, and other critical automotive systems.

Essential for honing hydraulic valve bodies to ensure smooth operation and longevity.

Used in the production of high-precision aerospace components where reliability and performance are critical.

Material: The material of the reamer should be suitable for the specific application.

Precision Requirements: Consider the level of precision required for your application.

Customization Needs: Determine if a standard or customized solution is best for your needs.

Engage with Halnn’s experts to identify the best honing reamer for your specific application. Our team is always ready to assist in making the right choice.

Regular Cleaning: Keep the reamers clean to prevent buildup of materials that can affect performance.

Proper Storage: Store in a dry, secure place to prevent damage and corrosion.

Implement a regular maintenance schedule to check for signs of wear and ensure the reamers are always in optimal condition.

Monitor for signs such as reduced performance, increased friction, and visible wear. Replace the reamer when these signs appear to maintain precision.

“Our production efficiency increased significantly after switching to Halnn’s diamond honing reamers. The precision and durability are unmatched.” - Automotive Industry Client

Read our detailed case studies to see how Halnn’s honing reamers have helped various clients achieve their manufacturing goals.

A valve body honing reamer is a precision tool used to finish the inner surfaces of valve bodies. It ensures high accuracy and smoothness, which are crucial for the optimal performance of valves in various applications, such as automotive, hydraulic, and aerospace industries.

Precision is vital in valve body honing because it directly affects the performance, efficiency, and lifespan of the valve. High precision reduces friction, wear, and tear, ensuring smooth and reliable operation of the valve.

Valve body honing reamers are typically made from high-quality steel or carbide. For enhanced durability and performance, these materials are often coated with diamond.

Diamond honing reamers offer superior hardness and durability, improved surface finishes, and longer tool life compared to other abrasive materials. They are ideal for machining hard materials and provide cost-effectiveness over the long term.

Stationary diamond Reamers: These are designed for specific, repeatable tasks where the dimensions do not change frequently.

Adjustable Diamond Honing Reamers: These provide flexibility to accommodate various sizes and are suitable for applications requiring different tolerances.

Yes, Halnn offers customized solutions to meet specific client requirements. Our experts can help design and manufacture honing reamers tailored to your unique needs.

Consider the material, precision requirements, and whether you need a standard or customized solution. Consulting with experts, like those at Halnn, can help you make the best choice for your specific application.

Regular cleaning, proper storage, and adhering to a maintenance schedule are crucial for maintaining your honing reamer. Monitor for signs of wear and replace the reamer when performance decreases to maintain precision.

Signs that a honing reamer needs to be replaced include reduced performance, increased friction, and visible wear. Regular monitoring and maintenance can help identify these signs early.

Valve body honing reamers are commonly used in the automotive, hydraulic, and aerospace industries. They are essential for achieving the high precision and smooth finishes required in these applications.

Valve body honing reamers are essential tools for achieving precision and durability in various industrial applications. At Halnn, we are committed to providing top-quality honing reamers that meet the highest standards. Whether you need standard or customized solutions, our expertise ensures you get the best tools for your needs.

For more information or to place an order, visit our website: https://www.halnncbn.com/. You can also reach us via email at halnntools@halnn-group.com or WhatsApp at +8615515925975.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.