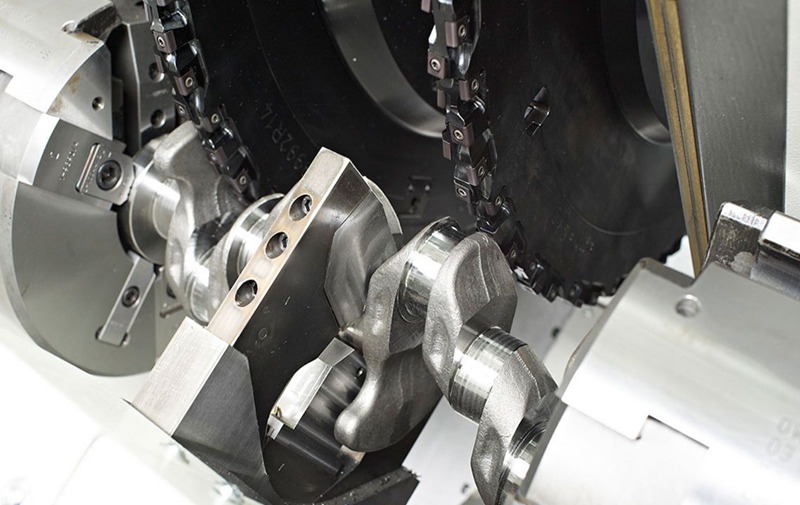

In the realm of internal combustion engines, the camshaft plays a pivotal role in ensuring the precise movement and synchronization of engine valves. This critical component relies on high-quality milling tools to achieve the precision necessary for optimal engine performance. As a leader in advanced machining solutions, Halnn offers a comprehensive range of camshaft milling inserts designed to meet the rigorous demands of modern manufacturing. This article delves into the essential aspects of camshaft milling inserts, providing valuable insights into their importance, types, features, and applications.

Camshaft milling inserts are essential for achieving the precision and efficiency required in camshaft production. These inserts not only influence the quality of the finished camshaft but also play a significant role in reducing production costs and improving overall manufacturing efficiency. High-quality milling inserts ensure that the camshaft's lobes, journals, and other critical surfaces are machined to exact specifications, which is crucial for the performance, durability, and longevity of the engine.

Halnn’s expertise in developing camshaft milling tools is grounded in our commitment to innovation and quality. Our inserts are engineered to withstand the extreme conditions of high-speed machining, ensuring consistent performance and long tool life.

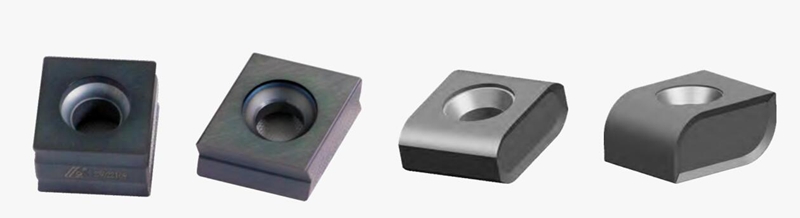

Halnn provides a variety of camshaft milling inserts tailored to meet the diverse needs of the automotive and manufacturing industries. Our product range includes:

Solid carbide inserts are known for their exceptional hardness and wear resistance, making them ideal for machining camshafts. These inserts are designed to handle high-speed operations while maintaining the precision required for complex camshaft geometries.

CBN inserts are perfect for high-speed finishing operations on hardened materials. They offer excellent thermal stability and wear resistance, which are critical for achieving a superior surface finish on camshafts. These inserts are particularly beneficial in applications where long tool life and minimal downtime are essential.

Halnn also offers custom milling inserts designed to meet specific machining requirements. Whether you need inserts for unique camshaft profiles or specialized applications, our team can develop tailored solutions that enhance your production capabilities.

Selecting the right camshaft milling insert is crucial for achieving the desired balance between performance and cost-effectiveness. Here are some key features to consider:

The material composition of the insert plays a significant role in its performance. Halnn’s inserts are made from premium materials like solid carbide and CBN, which provide excellent wear resistance and durability.

The geometry of the cutting edge impacts the insert’s ability to produce a smooth finish while minimizing tool wear. Our inserts are designed with optimized edge geometries to ensure efficient chip removal and high surface quality.

Coatings such as PVD (Physical Vapor Deposition) or CVD (Chemical Vapor Deposition) enhance the performance of the inserts by reducing friction and heat buildup. These coatings extend tool life and improve machining efficiency.

Inserts with multiple cutting edges allow for higher productivity and reduced tooling costs. Halnn’s inserts are designed with up to eight cutting edges, providing a cost-effective solution for high-volume camshaft production.

Camshaft milling inserts from Halnn are used in a variety of applications, including:

The primary use of camshaft milling inserts is in the automotive industry, where they are essential for the mass production of camshafts. These inserts help achieve the precision required for modern engines, which demand lower fuel consumption and reduced emissions.

Beyond automotive manufacturing, camshaft milling inserts are also used in other sectors of precision engineering where high accuracy and consistency are critical.

For manufacturers engaged in large-scale production, Halnn’s inserts offer the durability and efficiency needed to maintain high output levels while minimizing tooling costs.

Choosing the right camshaft milling insert involves several considerations:

Ensure that the insert material is compatible with the camshaft material (e.g., cast iron, steel) to prevent premature wear and achieve the desired surface finish.

Select inserts that are designed to work with your specific milling machines to optimize performance and tool life.

Consider factors such as speed, feed rate, and the required surface finish when selecting your inserts. Consulting with experts, like those at Halnn, can help you make the best choice for your application.

Halnn is at the forefront of innovation in camshaft milling technology. Our research and development efforts focus on creating advanced materials, enhancing coating technologies, and improving insert geometries to meet the evolving demands of the industry. Some of the latest innovations include:

Advanced Materials: Development of new materials that offer higher hardness and thermal stability.

Enhanced Coatings: Innovations in coating technologies that reduce friction, extend tool life, and improve overall machining performance.

Precision Engineering: Continuous improvements in insert design to achieve higher precision and consistency in camshaft milling.

To maximize the lifespan of your camshaft milling inserts, follow these maintenance tips:

Use the inserts according to the manufacturer’s recommendations to prevent excessive wear and ensure consistent performance.

Store inserts in a clean, dry environment to avoid damage and contamination. Proper handling is also crucial to prevent chipping and other forms of damage.

Conduct routine inspections to check for signs of wear or damage. Replace inserts as needed to maintain optimal machining performance.

Halnn is a trusted name in the machining industry, known for our high-quality camshaft milling inserts and tools. Our products are designed to meet the demanding requirements of modern manufacturing, offering reliability, precision, and cost-effectiveness. We are committed to providing our customers with innovative solutions that enhance productivity and reduce operational costs.

Whether you need standard camshaft milling inserts or custom-engineered solutions, Halnn has the expertise and technology to meet your needs. Contact us today to learn more about our products and how we can help you achieve your manufacturing goals.

Camshaft milling inserts are specialized cutting tools used in the milling process to shape and finish camshafts in internal combustion engines. They are crucial for achieving the precise dimensions and surface finishes required for the camshaft to function properly. High-quality inserts ensure the camshaft’s durability and performance, which is essential for the engine's overall efficiency.

Camshaft milling inserts are typically made from materials such as solid carbide and cubic boron nitride (CBN). These materials offer excellent hardness, wear resistance, and thermal stability, making them ideal for high-speed machining of camshafts.

Camshaft milling inserts are designed to remove material from the camshaft with precision. Their sharp cutting edges and optimized geometries ensure that the camshaft’s lobes, journals, and other critical surfaces are machined to exact specifications. This precision is vital for the camshaft’s role in controlling valve movement and synchronization in the engine.

Halnn’s camshaft milling inserts offer several benefits, including:

Increased Tool Life: Made from durable materials like carbide and CBN, Halnn’s inserts resist wear and last longer.

High Precision: Optimized geometries and advanced coatings provide superior cutting performance and surface finishes.

Cost Efficiency: Multiple cutting edges on Halnn’s inserts reduce tooling costs and increase productivity.

Custom Solutions: Halnn offers tailored insert designs to meet specific machining needs.

When selecting a camshaft milling insert, consider factors such as:

Material Compatibility: Ensure the insert material matches the camshaft material (e.g., cast iron, steel).

Machine Compatibility: The insert should be compatible with your milling machine for optimal performance.

Application Requirements: Evaluate the speed, feed rate, and desired surface finish. Consulting with Halnn’s experts can help you choose the most suitable insert.

Common challenges include maintaining dimensional accuracy, achieving the desired surface finish, and managing tool wear. Using high-quality camshaft milling inserts from Halnn can mitigate these challenges by providing consistent performance, longer tool life, and precise cutting action.

Yes, Halnn offers custom-engineered camshaft milling inserts designed to meet specific machining requirements. Whether you need inserts for unique camshaft profiles or specialized applications, Halnn’s team can develop solutions that enhance your production efficiency.

To maximize the lifespan of your inserts:

Follow recommended usage guidelines from the manufacturer.

Store and handle inserts properly to avoid damage.

Perform regular inspections to check for wear and replace inserts as needed.

Optimize machining parameters (speed, feed rate, etc.) based on the insert material and the camshaft being machined.

Halnn is at the forefront of innovation, offering advancements such as:

Enhanced Coating Technologies to reduce friction and improve tool life.

Advanced Material Compositions for better wear resistance and thermal stability.

Precision-Engineered Geometries for higher accuracy and surface quality in camshaft milling.

You can purchase Halnn camshaft milling inserts directly from our website or by contacting our sales team. Halnn offers a wide range of standard and custom milling inserts to meet your specific machining needs.

Camshaft milling inserts are a critical component in the production of high-quality camshafts. By choosing the right inserts, manufacturers can achieve the precision and efficiency required for modern engines. Halnn’s range of camshaft milling inserts offers superior performance, durability, and cost-effectiveness, making them the ideal choice for manufacturers looking to enhance their machining processes.

For more information on Halnn’s camshaft milling inserts and other machining solutions, visit our website or contact our team of experts.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.