In today's competitive manufacturing landscape, precision and efficiency are paramount. Indexable gun drill tools have emerged as a critical solution for achieving high-quality deep-hole drilling across various industries. At Halnn, we are committed to delivering top-notch carbide indexable gun drills that meet the exacting standards of our clients in aerospace, automotive, medical devices, and beyond. This article will explore the advantages, applications, and selection criteria for indexable gun drill tools, showcasing how Halnn leads the way in this specialized field.

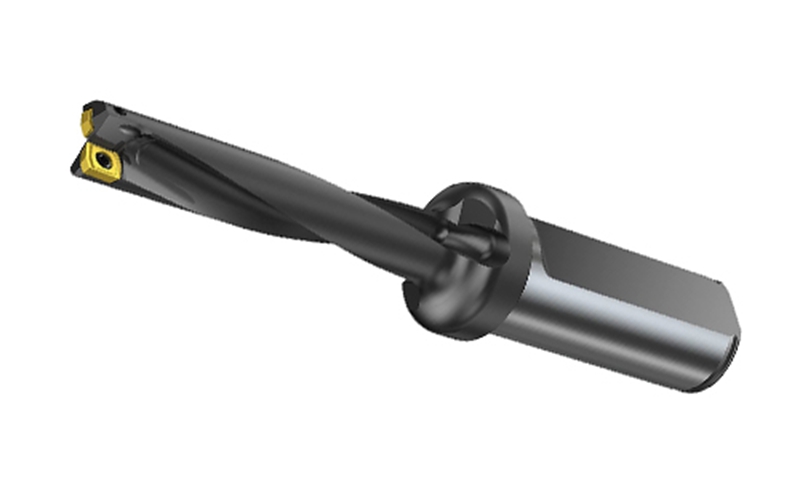

Indexable gun drill tools are specialized drilling instruments designed for deep-hole drilling applications. Unlike traditional gun drills, which feature a single, solid cutting tip, indexable gun drills use replaceable carbide inserts. This innovation allows for enhanced flexibility, cost savings, and tool longevity.

Carbide Insert: The replaceable cutting edge, made from durable carbide material, ensures precise and efficient cutting.

Drill Body: The main structure of the tool, which securely holds the carbide insert and connects to the drilling machine.

Coolant Channels: Integrated channels that facilitate the flow of coolant to the cutting edge, reducing heat and extending tool life.

Indexable gun drills offer exceptional precision, thanks to the carbide inserts' sharpness and consistency. This precision is crucial for applications where tolerance and accuracy are non-negotiable, such as in the aerospace and medical device industries.

The ability to replace only the carbide insert, rather than the entire drill, leads to significant cost savings. This feature also reduces inventory costs, as multiple insert types can be used with a single drill body.

Carbide inserts are known for their wear resistance and durability. The indexable design allows for quick replacement of worn inserts, minimizing downtime and extending the overall life of the tool.

Indexable gun drills can be easily customized to suit different materials and drilling conditions. This flexibility makes them suitable for a wide range of applications, from hard metals to softer alloys.

Maintenance is simplified with indexable gun drills. The ability to replace the insert without disassembling the entire tool reduces maintenance time and complexity, leading to increased productivity.

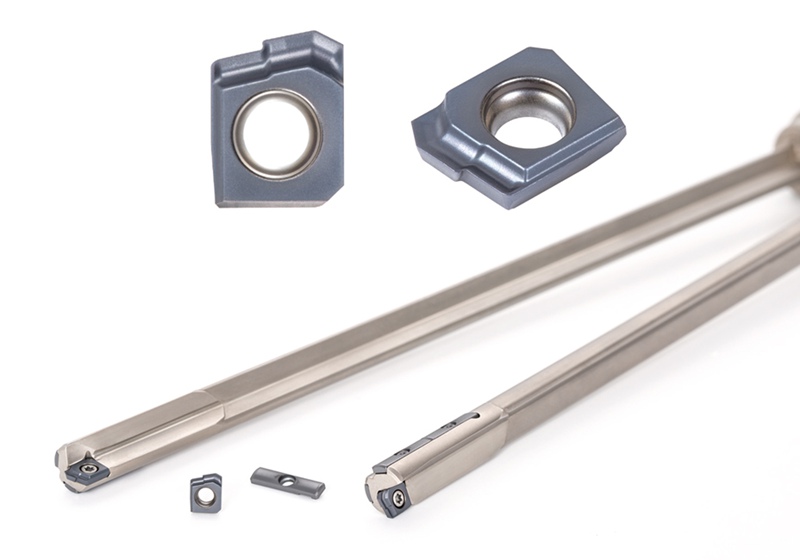

Single-edge indexable gun drills feature one cutting edge, making them ideal for applications requiring high precision and finish quality. They are commonly used in the aerospace and medical device industries.

Double-edge indexable gun drills have two cutting edges, offering faster drilling speeds. These tools are particularly effective in materials like cast iron and aluminum, where speed and efficiency are crucial.

Multi-edge indexable gun drills are designed for high-speed, high-volume production environments. With multiple cutting edges, these drills can achieve faster material removal rates, making them suitable for automotive and general manufacturing applications.

For unique or challenging applications, Halnn offers specialized indexable gun drills. These tools are custom-designed to meet specific requirements, ensuring optimal performance and longevity.

Choosing the right material and coating for your indexable gun drill insert is critical for achieving optimal performance.

Carbide: The most popular material for inserts due to its hardness, wear resistance, and ability to maintain a sharp cutting edge.

CBN (Cubic Boron Nitride): Ideal for hard and abrasive materials, offering excellent heat resistance.

PCD (Polycrystalline Diamond): Best suited for non-ferrous materials and composites, providing superior wear resistance.

TiN (Titanium Nitride): Increases wear resistance and reduces friction.

TiAlN (Titanium Aluminum Nitride): Offers higher heat resistance, suitable for high-speed applications.

DLC (Diamond-Like Coating): Provides extreme hardness and reduces adhesive wear, ideal for aluminum and other soft materials.

In the aerospace sector, the need for precision and reliability is critical. Halnn’s indexable gun drill tools are used to produce engine components, structural parts, and landing gear, ensuring that every hole is drilled with exacting accuracy.

The automotive industry relies on indexable gun drill tools for the production of engine blocks, transmission parts, and suspension systems. Halnn’s tools enable manufacturers to meet tight tolerances and deliver high-quality products consistently.

The medical device industry demands precision and cleanliness. Halnn’s carbide indexable gun drills are used to manufacture intricate parts for surgical instruments, implants, and diagnostic equipment, where precision is crucial for patient safety.

The harsh environments of oil and gas exploration require tools that can withstand extreme conditions. Halnn’s indexable gun drills are designed to drill deep holes in challenging materials, providing the durability and reliability needed in this sector.

Halnn’s indexable gun drill tools are versatile enough for a broad range of general engineering applications. Whether drilling in steel, aluminum, or composites, these tools deliver consistent performance and efficiency.

Selecting the right tool depends on the material you’re drilling. Harder materials like steel and titanium may require carbide or CBN inserts, while softer materials like aluminum benefit from PCD or coated carbide inserts.

The depth and diameter of the hole will influence your choice of indexable gun drill. Halnn offers a range of sizes to accommodate various applications, ensuring optimal tool stability and performance.

Ensure that the indexable gun drill tool you choose is compatible with your drilling machine. Halnn’s experts can assist in selecting the right tool for your specific machine and application needs.

While indexable gun drill tools may have a higher upfront cost, their long-term benefits, including reduced maintenance and replacement costs, make them a cost-effective choice. Halnn offers a range of options to suit different budgets and applications.

Regular inspections help identify wear and tear before it impacts performance. Cleaning the tool after each use prevents debris buildup and prolongs tool life.

Proper handling and usage are essential for maximizing the life of your indexable gun drill tools. Follow Halnn’s guidelines for safe and effective use to avoid damage and ensure optimal performance.

When the insert becomes dull, re-sharpening or replacement is necessary. Halnn offers professional re-sharpening services to restore your inserts to their original sharpness, extending tool life and reducing costs.

Halnn offers a comprehensive range of indexable gun drill tools, including single-edge, double-edge, and specialized drills. Our products are designed to meet the diverse needs of industries such as aerospace, automotive, and medical devices.

We understand that each project has unique requirements. Halnn provides customization options for indexable gun drill tools, including specific sizes, lengths, and coatings. Our team will work closely with you to develop a solution that meets your exact needs.

At Halnn, quality is at the forefront of our operations. Our indexable gun drill tools undergo rigorous testing and adhere to the highest industry standards, ensuring that our clients receive reliable, high-performance tools.

A: Carbide indexable gun drills offer superior precision, durability, and cost-effectiveness. The replaceable carbide inserts reduce the need for frequent tool changes, enhancing productivity.

A: The choice of insert material depends on the material you’re drilling. For hard materials, carbide or CBN inserts are ideal. For softer materials, consider PCD or coated carbide inserts.

A: Yes, Halnn offers customization options to meet the unique requirements of different industries and applications. Our experts will work with you to design the perfect tool for your needs.

A: Insert replacement frequency depends on usage and the material being drilled. Regular inspections will help determine when an insert needs to be replaced or re-sharpened.

Indexable gun drill tools are an essential asset for achieving precision, efficiency, and cost savings in deep-hole drilling applications. Halnn is dedicated to providing high-quality carbide indexable gun drills that meet the specific needs of various industries. With our extensive product range, customization options, and commitment to quality, Halnn is your ideal partner for all your drilling needs.

Ready to enhance your drilling operations with top-of-the-line indexable gun drill tools? Contact Halnn today to explore our product range and discover how we can help you achieve superior drilling performance. Visit our website or reach out to our team for a consultation and take the first step towards optimizing your production process.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.