In the world of industrial machining, ceramic inserts have emerged as a reliable and durable solution for high-speed applications. Offering superior hardness, heat resistance, and longevity, ceramic inserts are widely used in various industries, including aerospace, automotive, and heavy machinery. As one of the leading suppliers of ceramic inserts, Halnn specializes in providing high-quality, cost-effective solutions tailored to specific machining needs.

In this article, we will explore the factors that influence the price of ceramic inserts, including their composition, manufacturing process, and market demand. We will also delve into how Halnn positions itself in the ceramic insert market, offering competitive pricing without compromising on performance and quality.

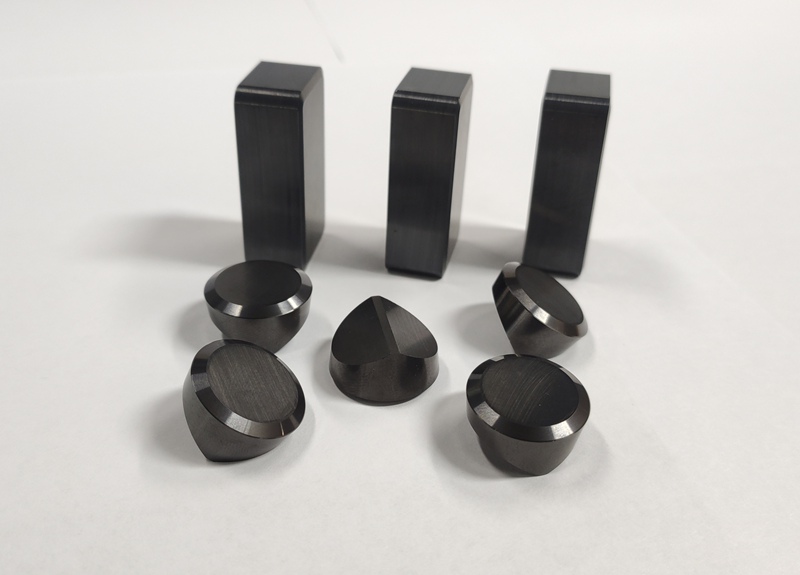

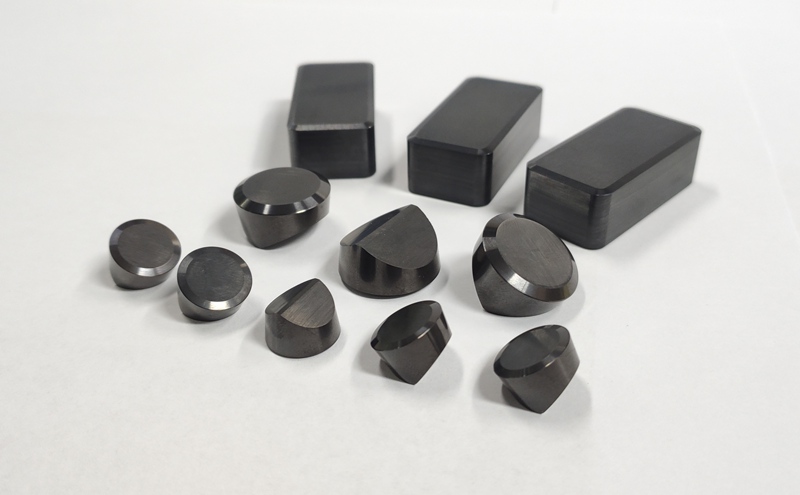

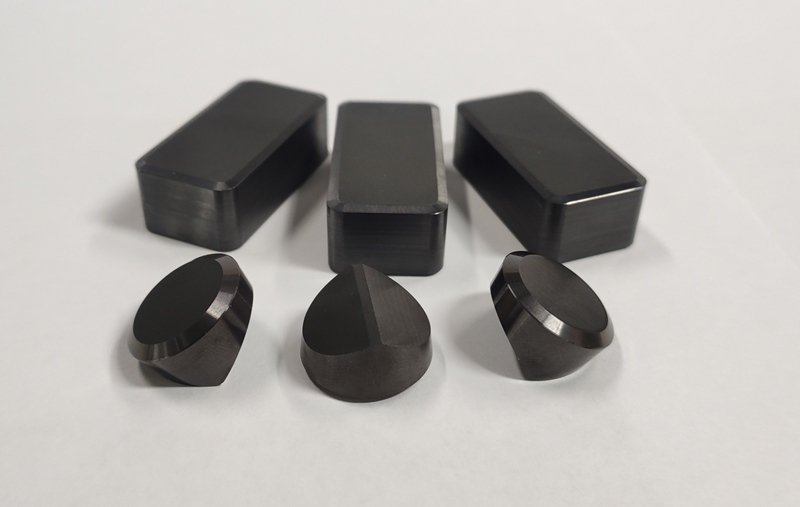

Ceramic inserts are cutting tools made from advanced ceramic materials such as alumina, silicon nitride, and zirconia. These inserts are engineered for high-speed machining and can withstand extreme temperatures and pressures that would degrade other materials like carbide or CBN (Cubic Boron Nitride). Ceramic inserts are widely used in finishing operations, particularly for hard-to-machine materials like high-temperature alloys and hardened steel.

CNGN Series |

SNGA Series |

RNGN Series |

RCGN Series |

RCGX-Y Series |

RCGX-V Series |

DNGN Series |

TNGN Series |

SCGN Series |

CNGO Series |

CNGL Series |

RNGS Series |

DNGL Series |

RCGO Series |

TNGO Series |

RCGS Series |

SNGA Series |

CNGA Series |

TNGA Series |

WNGA Series |

Several key factors impact the price of ceramic inserts, from raw material selection to manufacturing complexity and brand positioning. Understanding these factors will help you make informed purchasing decisions and select the best ceramic insert for your needs.

The type of ceramic material used in the insert significantly affects its price. Silicon nitride and zirconia ceramic inserts, for example, often come at a higher cost due to their enhanced performance characteristics like toughness and resistance to wear and thermal shock. In contrast, alumina-based inserts tend to be more affordable but may not offer the same level of performance in extreme conditions.

The precision and complexity of the manufacturing process also contribute to the price of ceramic inserts. Inserts that undergo advanced sintering processes or require additional coatings to improve their durability and performance are typically more expensive. At Halnn, we use cutting-edge manufacturing technologies to ensure that our ceramic inserts meet the highest industry standards.

The reputation and expertise of the manufacturer play a crucial role in pricing. Established brands like Halnn invest in research and development, stringent quality control, and after-sales support, which reflects in the price of their products. Cheaper alternatives may lack the durability and performance needed for demanding applications, leading to higher long-term costs due to frequent replacements and downtime.

Coated ceramic inserts, which offer enhanced performance in specific applications, generally cost more than uncoated ones. Additionally, custom-made inserts designed for unique machining requirements may also carry a premium due to the additional design and production effort involved. Halnn offers both standard and custom ceramic inserts, ensuring that our clients receive the most efficient solution for their specific needs.

The price of ceramic inserts can vary widely depending on the factors mentioned above. On average, ceramic inserts range from $10 to $50 per insert, with high-end or specialized inserts costing more. Standard alumina ceramic inserts are usually more affordable, while silicon nitride or zirconia inserts fall into the premium category.

The application of the ceramic insert often dictates its price as well. For example, ceramic inserts designed for high-precision aerospace components or heavy-duty automotive machining will typically cost more than those used for general-purpose cutting operations. Understanding your specific application requirements is essential for selecting the right ceramic insert at the right price.

When comparing ceramic inserts to other materials like carbide or CBN inserts, ceramic inserts generally offer better performance in high-speed, high-temperature applications, but they come at a higher price. However, their longevity and reduced downtime often make them a more cost-effective solution in the long run, especially for demanding applications.

At Halnn, we pride ourselves on offering high-quality ceramic inserts that deliver superior performance at competitive prices. Our commitment to innovation and precision machining has made us a trusted partner in the machining industry, particularly for high-performance and hard-to-machine materials.

Halnn positions itself as a leader in the ceramic insert market by offering value-driven pricing. We achieve this through efficient manufacturing processes, economies of scale, and a focus on customer satisfaction. Our ceramic inserts are designed to provide maximum efficiency and durability, helping you reduce costs in the long term.

In addition to offering competitive pricing on standard ceramic inserts, Halnn also provides custom solutions tailored to your specific needs. Whether you require coated inserts for high-precision applications or custom geometries for unique machining tasks, Halnn can deliver high-performance solutions at a reasonable cost.

When selecting ceramic inserts, it’s essential to balance price with performance. Cheaper inserts may seem attractive, but they often fail to deliver the same level of durability and precision as premium options. Here are a few tips for making the right choice:

Assess Your Application Needs: Consider the material you are machining, the cutting speed, and the environment. For high-speed, high-temperature applications, investing in a more expensive ceramic insert will likely pay off in terms of reduced downtime and longer tool life.

Consider Long-Term Costs: While ceramic inserts may have a higher upfront cost, their durability and ability to withstand extreme conditions often result in lower overall costs compared to carbide or CBN inserts.

Consult with Experts: At Halnn, our team of experts can help you choose the best ceramic insert for your specific needs, ensuring that you get the best performance and value for your investment.

The price of ceramic inserts is influenced by several factors, including the material composition (e.g., alumina, silicon nitride, zirconia), the complexity of the manufacturing process, coatings applied for performance enhancement, and the brand or supplier's reputation. Customization and specific application needs can also affect the cost.

Ceramic inserts usually range from $10 to $50 per insert, depending on factors like material, application, and supplier. More specialized inserts designed for high-performance applications may cost more.

Yes, silicon nitride ceramic inserts are generally more expensive than alumina-based ones due to their superior toughness, wear resistance, and ability to handle thermal shock. They are often used in more demanding machining environments.

Ceramic inserts typically offer higher heat resistance, greater hardness, and longer tool life compared to carbide inserts. These properties make ceramic inserts more effective for high-speed machining and difficult-to-machine materials, which justifies their higher price.

Yes, Halnn offers competitive pricing on a range of ceramic inserts. We focus on delivering high-performance tools at a reasonable cost, ensuring that our customers receive excellent value for their investment.

Yes, Halnn offers discounts for bulk orders of ceramic inserts. The more you purchase, the lower the price per unit. Contact us directly for specific pricing details on larger quantities.

Customized ceramic inserts usually come at a higher price due to the additional effort required in design and production. However, they are tailored to meet specific needs and often provide greater efficiency and durability, which can reduce costs in the long term.

Coated ceramic inserts are generally more expensive than uncoated ones because coatings enhance performance by improving wear resistance and extending tool life. These benefits often justify the higher price, especially in high-speed or precision applications.

Yes, the price of ceramic inserts can fluctuate based on changes in raw material costs, demand in the market, and advancements in manufacturing technologies. Global economic factors can also play a role in price changes.

You can contact Halnn directly for a detailed price quote. Provide information about your specific application, the type of insert you need, and the quantity required, and we will offer competitive pricing tailored to your needs.

Ceramic inserts are a vital tool in modern machining, particularly for high-speed and high-temperature applications. Understanding the factors that influence ceramic insert prices helps you make informed decisions when selecting the right tool for your operations. At Halnn, we are committed to providing high-quality ceramic inserts that deliver excellent performance at competitive prices. Whether you're looking for standard inserts or custom solutions, Halnn has the expertise and products to meet your needs.

For more information on our ceramic inserts and pricing, feel free to contact Halnn today!

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.