In the world of machining, ceramic inserts play a vital role in providing enhanced performance, especially in high-speed, high-temperature, and abrasive conditions. Whether it’s automotive, aerospace, or heavy machinery, manufacturers depend on reliable ceramic inserts to ensure durability and efficiency in their operations. But not all ceramic insert manufacturers are the same. Choosing the right manufacturer directly impacts the quality of the inserts you receive and the performance of your machining processes.

At Halnn, we take pride in being a leading ceramic insert manufacturer, offering advanced solutions that exceed industry standards. This article will explore the key benefits of ceramic inserts, why choosing a reputable manufacturer matters, and why Halnn should be your top choice for high-performance ceramic inserts.

Ceramic inserts are a type of cutting tool made from advanced ceramic materials, often used in applications where heat resistance, hardness, and wear resistance are critical. Unlike carbide inserts, ceramic inserts can maintain their integrity at high temperatures, making them ideal for high-speed machining and dry cutting environments.

High Wear Resistance: Ceramic inserts maintain their sharpness and hardness over extended periods, resulting in longer tool life.

Heat Resistance: Ceramic materials can withstand higher temperatures than carbide, enabling faster cutting speeds.

Surface Finish: Due to their rigidity and resistance to wear, ceramic inserts provide better surface finishes, especially in finishing applications.

Halnn's ceramic inserts, particularly, are designed to offer superior performance in high-speed operations and challenging machining conditions, reducing downtime and improving productivity.

When selecting a ceramic insert manufacturer, product quality, consistency, and performance are crucial. A reliable manufacturer ensures that you receive inserts that meet your machining needs without sacrificing quality. Here’s why partnering with a reputable manufacturer like Halnn is important:

Material Integrity: The quality of ceramic materials can vary, and only a reputable manufacturer can guarantee top-tier materials that withstand the rigors of high-speed machining.

Precision Engineering: Reputable manufacturers employ advanced engineering techniques to ensure that each insert is machined to precise tolerances, reducing the chances of breakage or failure during use.

Custom Solutions: Many manufacturers offer off-the-shelf products, but a trusted manufacturer can provide customized solutions that align with specific requirements.

At Halnn, we prioritize excellence in every step of our manufacturing process, ensuring that our ceramic inserts meet the highest standards of quality, durability, and performance.

Halnn has been at the forefront of ceramic insert innovation, continuously advancing our technology and product offerings to stay ahead of industry demands. Our expertise extends beyond standard solutions, and we are committed to providing inserts that offer superior performance even in the most demanding conditions.

We use only the finest ceramic materials in our inserts, ensuring that they deliver exceptional wear resistance and high-temperature stability. Our ceramic inserts excel in machining difficult-to-cut materials like hardened steels and cast iron, reducing tool wear and increasing productivity.

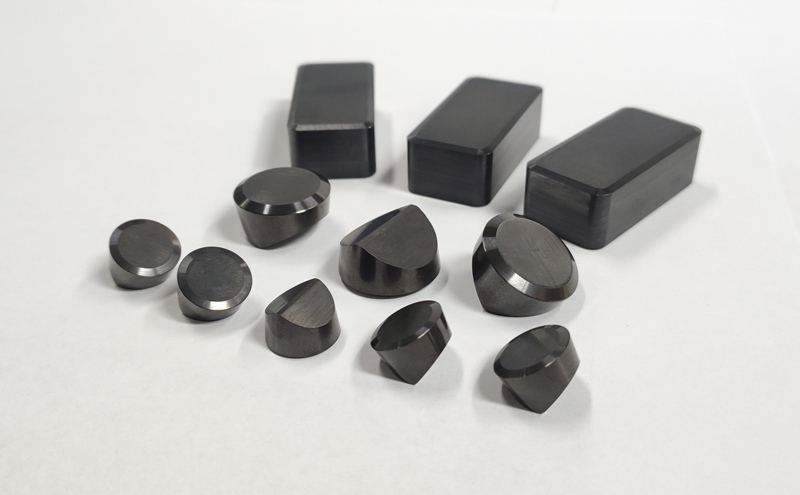

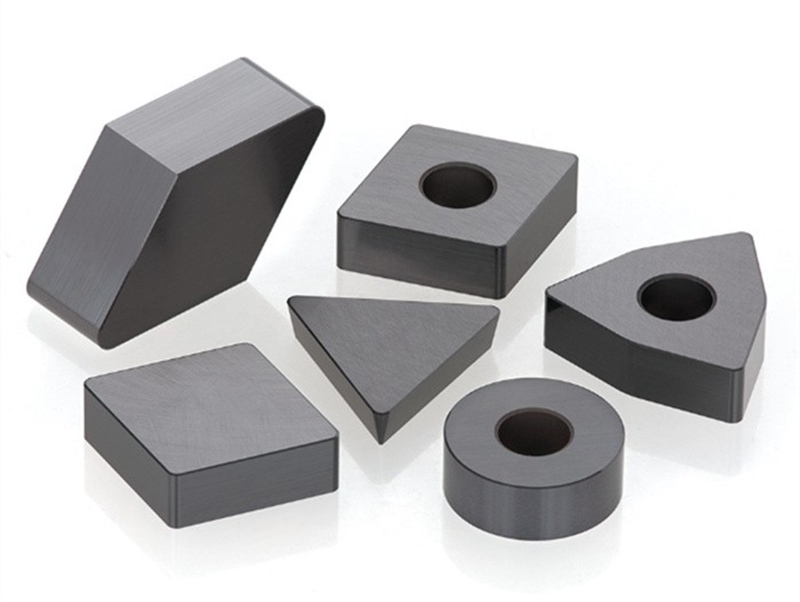

At Halnn, we understand that every application is unique. That’s why we offer customization options for our ceramic inserts, from specific geometries to unique material compositions. Whether you need inserts for high-speed cutting or roughing applications, we tailor our solutions to meet your exact specifications.

While quality and performance are our primary goals, we also understand the importance of cost-efficiency. Halnn offers competitive pricing on all our ceramic inserts, ensuring that you receive maximum value without compromising on quality.

Halnn serves customers worldwide, offering comprehensive support before, during, and after the sale. Our technical team is ready to assist with product selection, application guidance, and troubleshooting, ensuring that you get the best results from our ceramic inserts.

Halnn employs a highly controlled manufacturing process that starts with material selection and ends with rigorous quality testing. We use state-of-the-art machinery and precision tooling to create ceramic inserts that are accurate and reliable. Our manufacturing process includes:

Material Preparation: High-purity ceramic powders are mixed and prepared for pressing.

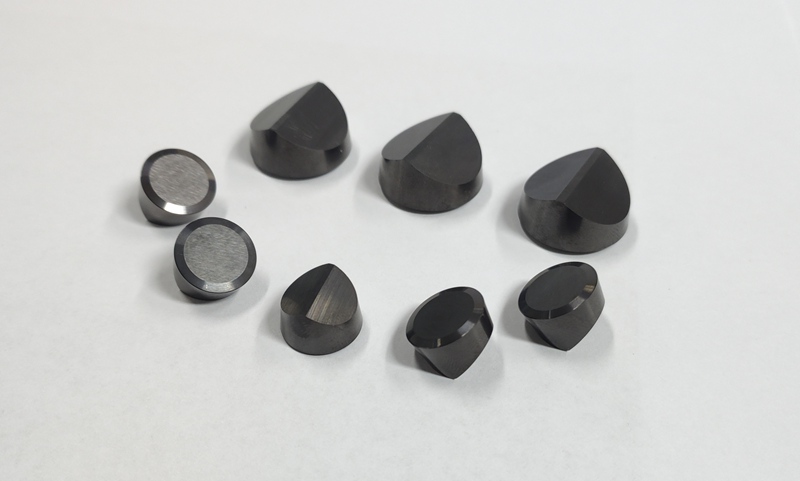

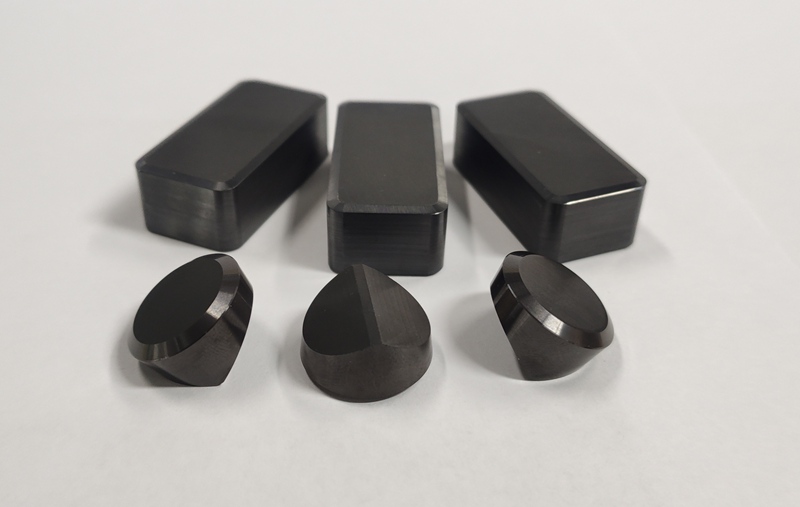

Shaping: The material is pressed into the desired insert shape with exacting precision.

Sintering: The inserts are sintered at high temperatures to achieve optimal hardness and strength.

Finishing: The inserts undergo finishing processes such as grinding, coating, and final inspection to ensure they meet our stringent quality standards.

By adhering to these meticulous processes, Halnn ensures that our ceramic inserts are of the highest quality and ready to perform in the toughest conditions.

Halnn’s ceramic inserts are trusted by a wide range of industries, including:

Automotive: For machining high-strength steels and cast iron in engine components and transmission parts.

Aerospace: For high-temperature machining of heat-resistant superalloys and other aerospace materials.

Heavy Machinery: For turning and milling in large-scale industrial applications where tool life and precision are essential.

We are proud to serve diverse industries and help them achieve greater efficiency and performance through our advanced ceramic inserts.

Here’s a quick checklist to help you choose the right ceramic insert manufacturer:

Experience and Reputation: Look for manufacturers with a proven track record and industry recognition.

Material Quality: Ensure the manufacturer uses high-quality, advanced ceramic materials.

Customization Capabilities: Choose a manufacturer that can provide custom inserts tailored to your specific needs.

Technical Support: Ensure the manufacturer offers robust support and assistance throughout the process.

Competitive Pricing: Find a manufacturer that provides high-quality products at competitive prices.

Halnn checks all these boxes, making us the ideal partner for your ceramic insert needs.

A ceramic insert manufacturer is a company that specializes in designing, producing, and distributing ceramic cutting inserts. These inserts are used in machining applications for materials like cast iron, hardened steel, and superalloys due to their high wear resistance and ability to withstand high temperatures.

Manufacturers typically produce several types of ceramic inserts, including silicon nitride, aluminum oxide, and zirconium oxide ceramic inserts. These can come in a variety of shapes (like square, triangle, round), edge types, and geometries to suit different machining applications.

Choosing a reputable ceramic insert manufacturer like Halnn ensures you receive high-performance cutting tools that meet industry standards. Halnn specializes in innovative ceramic inserts that enhance machining efficiency, extend tool life, and maintain precision, even in demanding applications.

Ceramic inserts are widely used in industries such as automotive, aerospace, heavy equipment manufacturing, and energy production. These industries require reliable and durable inserts for tasks like turning, milling, and drilling hard materials, making ceramic inserts an essential part of their machining operations.

When selecting a ceramic insert manufacturer, consider their experience, range of products, customization options, material quality, and customer support. A good manufacturer like Halnn provides tailored solutions, offers a variety of insert types for different applications, and ensures consistent product performance.

Halnn uses advanced production technologies, rigorous testing, and stringent quality control processes to ensure the highest standards of its ceramic inserts. This results in reliable, durable inserts that enhance productivity and reduce operational costs.

Choosing the right ceramic insert manufacturer is crucial for ensuring the efficiency and performance of your machining processes. At Halnn, we combine industry-leading expertise, high-quality materials, and custom solutions to deliver ceramic inserts that meet the demands of modern manufacturing. Whether you need standard or customized inserts, Halnn is your trusted partner for high-performance ceramic tooling.

Contact Halnn today to learn more about our ceramic inserts and how we can help optimize your machining operations.

Our website: https://www.halnncbn.com/

Email: halnntools@halnn-group.com

WhatsApp: +8613271562251

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.